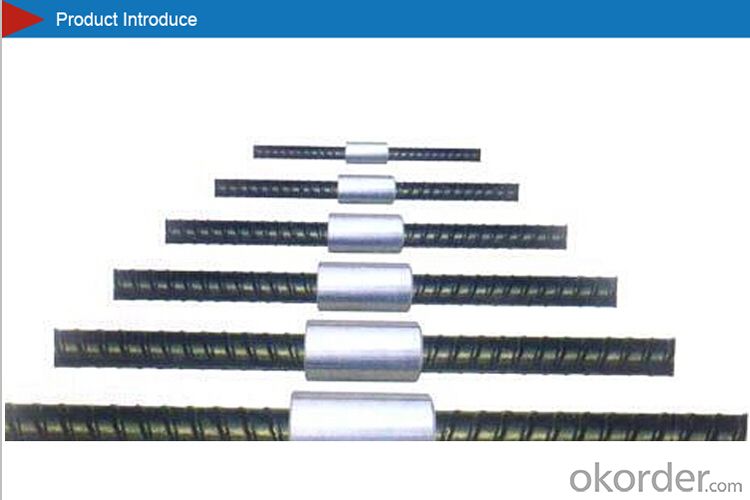

Parallel Thread Rebar Coupler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Material:45#high quality carbon steel.

2.Application: 12--50mm.

3.High strength,low cost,simple operation.

1#

| Coupler Size | Outer Dia(±0.5mm) | Inner Dia(±0.5mm) | Length(±2mm) | Thread Pitch(mm) | Thread Angle(º) | Weight/Pc(kg) |

| D12 | 19 | 10.28 | 35 | M12*1.75P | 60/75 | 0.036 |

| D14 | 21 | 12.55 | 38 | M14.8*2.5P | 60/75 | 0.068 |

| D16 | 24 | 14.50 | 43 | M16.8*2.5P | 60/75 | 0.099 |

| D18 | 27 | 16.35 | 48 | M18.6*2.5P | 60/75 | 0.125 |

| D20 | 29 | 18.45 | 53 | M20.6*2.5P | 60/75 | 0.180 |

| D22 | 33 | 20.35 | 58 | M22.6*2.5P | 60/75 | 0.205 |

| D25 | 37 | 23.15 | 63 | M26.0*3.0P | 60/75 | 0.317 |

| D28 | 41 | 25.95 | 68 | M28.6*3.0P | 60/75 | 0.399 |

| D32 | 47 | 30.15 | 80 | M32.8*3.0P | 60/75 | 0.640 |

| D36 | 54 | 33.85 | 83 | M36.7*3.5P | 60/75 | 0.900 |

| D40 | 59 | 37.55 | 88 | M40.4*3.5P | 60/75 | 1.099 |

| D50 | 74 | 47.10 | 125 | M50.4*3.5P | 75 | 1.298 |

3#

| Coupler Size | OD(±0.5mm) | Length(±2mm) | Thread Pitch | Thread Angle(º) | G/W(kgs) |

| D14 | 22 | 38 | 2.5 | 75 | 0.068 |

| D16 | 25 | 43 | 2.5 | 75 | 0.099 |

| D18 | 28 | 48 | 2.5 | 75 | 0.125 |

| D20 | 30 | 53 | 2.5 | 75 | 0.180 |

| D22 | 34 | 58 | 2.5 | 75 | 0.205 |

| D25 | 38 | 63 | 3.0 | 75 | 0.317 |

| D28 | 42 | 68 | 3.0 | 75 | 0.399 |

| D32 | 48 | 80 | 3.0 | 75 | 0.640 |

| D36 | 55 | 83 | 3.5 | 75 | 0.900 |

| D40 | 59 | 88 | 3.5 | 75 | 1.099 |

Rebar Coupler Advantages:

----Adopt National Standard 45# igh quality carbon steelas raw meterial.

----High strength, tensile test usually more than 600Mpa,Tensile strength can reach 110%of yiled strength of parent rebar.

----The product has passed ISO9001 International Quality System Certification.

----We can design,produce weldable or other type rebar couper as per customers` requirement.

Tengzhong Machinery Co.,Ltd

A processional manufacture of rebar mechanical splicing equipment,rebar processing machinery,rebar coupler and related products.It is a membership of construction machinery trade of China quality cotrol association.

- Q: ... the two methods are similar

- Scaffolding method is not mathematical method. It's just the way to provide people some knowledge in working on the problem. Well, to use the standard algorithm, see this guide.

- Q: Can steel tube couplers be used in scaffolding projects with restricted weight limits?

- When working on scaffolding projects with weight restrictions, it is important to take into account and follow the weight limits set by the manufacturer and relevant regulations. Due to their strength and durability, steel tube couplers are frequently employed in scaffolding. However, in cases where weight limits are constrained, it is vital to make sure that the total weight of the scaffolding structure, platforms, and any extra equipment or materials does not surpass the specified limits. This might involve using lighter materials, redistributing the weight more evenly, or employing additional support structures to decrease the load on the scaffolding. Ultimately, conducting a careful assessment and planning of the scaffolding project is crucial in order to comply with weight limits and maintain a safe working environment.

- Q: What are the common sizes and dimensions of steel tube couplers used in scaffolding?

- The common sizes and dimensions of steel tube couplers used in scaffolding typically range from 48.3mm to 60.3mm in outer diameter, with a wall thickness of around 3.2mm to 4mm. These couplers are designed to connect two scaffolding tubes together securely, providing stability and strength to the overall scaffold structure.

- Q: Are steel tube couplers adjustable for different heights in scaffolding with restricted access?

- No, steel tube couplers are not adjustable for different heights in scaffolding with restricted access. Steel tube couplers are used to connect and secure steel tubes in scaffolding systems, but they do not have the capability to adjust the height of the scaffolding. In situations where there is restricted access and the scaffolding needs to be adjusted to different heights, alternative solutions such as adjustable base plates, telescopic props, or adjustable scaffolding systems should be considered. These options provide the flexibility to adjust the height of the scaffolding in restricted areas without the need for disassembling and reassembling the entire structure.

- Q: Are steel tube couplers resistant to vibration or movement in scaffolding structures?

- Steel tube couplers are generally known for their resistance to vibration and movement in scaffolding structures. Due to the strength and rigidity of steel, it is highly capable of withstanding vibrations and movements. The purpose of steel tube couplers is to securely connect two or more steel tubes, creating a stable and dependable connection. To ensure a secure grip and minimize any potential movement, these couplers are typically fastened with nuts and bolts. Furthermore, it is common for steel tube couplers to undergo testing and certification to meet safety standards, providing additional assurance of their resistance to vibration and movement. It is important to emphasize, however, that proper installation and regular inspection are vital in maintaining the stability and integrity of the scaffolding structure.

- Q: Is there any secondary construction division exams over the years? (Municipal) can pass a thank you

- This is not to say which specification is explained! Should be considered! See the load check and then choose whether to double pole!

- Q: We don't see it around much anymore but the Scaffold Match was a big deal back in the 80's. Who invented the match? Who were the participants, and who won? When (the year will suffice) and where did the first Scaffold Match take place?Whoever gets the most right gets Best Answer.

- I think ECW did. There's a scaffold match between Tommy Dreamer and someone else. I don't know his opponents name.

- Q: What are the common methods of disassembling scaffolding structures with steel tube couplers?

- There are several common methods used for disassembling scaffolding structures with steel tube couplers. These methods include: 1. Sequential disassembly: This method involves removing the scaffolding components in the reverse order of their installation. Starting from the top, each level is dismantled one by one until the entire structure is taken apart. It is important to follow a systematic approach and ensure that all couplers are properly disconnected before removing the tubes. 2. Sectional disassembly: In this method, the scaffolding structure is divided into manageable sections, typically 6 to 8 feet long. Each section is then disassembled independently by removing the couplers and separating the tubes. This approach is commonly used when working with larger scaffolding structures that cannot be easily dismantled as a whole. 3. Drop disassembly: This method involves removing the horizontal members first, which are then allowed to drop to the ground or a lower level. Once the horizontal members are removed, the vertical tubes can be disassembled section by section. This method requires careful planning and coordination to ensure the safety of workers and prevent any potential hazards. 4. Use of dismantling tools: Various specialized tools can be used to aid in the disassembly process. Tools such as scaffolding spanners, ratchet wrenches, and pry bars can help loosen tight couplers and facilitate the removal of tubes. These tools are particularly useful when dealing with rusted or stubborn couplers that are difficult to detach. Regardless of the method chosen, it is crucial to follow proper safety guidelines and ensure that all workers are trained on the correct disassembly procedures. Regular inspection of the scaffolding components is also important to identify any damaged or worn-out parts that may need replacement before disassembly.

- Q: Are steel tube couplers compatible with scaffolding standards and regulations?

- Indeed, scaffolding standards and regulations deem steel tube couplers compatible. They serve as a prevalent and accepted technique for joining scaffolding tubes. These couplers are purposefully engineered to meet industry guidelines and regulations, guaranteeing the security and steadfastness of the scaffolding framework. Typically crafted from top-notch materials, steel tube couplers undergo rigorous testing to ensure they meet specific load-bearing requirements. Moreover, their design facilitates effortless installation and removal, granting construction workers and scaffolding contractors flexibility and convenience in constructing and dismantling scaffolding systems. As a result, these individuals can confidently incorporate steel tube couplers, knowing they adhere to the necessary standards and regulations.

- Q: What are the common failure modes of steel tube couplers in scaffolding?

- Several factors can be attributed to the common failure modes of steel tube couplers in scaffolding. One of these modes is overloading, which occurs when the weight or load applied to the scaffolding surpasses the coupler's maximum load capacity. As a result, the coupler can deform, crack, or even break, leading to a catastrophic failure of the entire scaffolding structure. Improper installation or assembly of the couplers is another failure mode to consider. If the couplers are not properly tightened or aligned, they can become loose or detached, posing a significant safety risk. This improper installation can also create gaps or misalignment between the tubes, compromising the overall strength and stability of the scaffold. The corrosion of steel tube couplers is yet another failure mode to be aware of. Over time, exposure to moisture, chemicals, or other corrosive agents can cause the couplers to rust or corrode. This weakens the structural integrity of the couplers, making them prone to failure under load. Fatigue failure is also common in steel tube couplers. The repeated application of loads, such as during the construction or dismantling of the scaffold, can lead to the development of cracks or fractures in the couplers over time. These cracks can propagate and eventually result in a complete failure of the coupler. Finally, poor quality or substandard manufacturing can contribute to failure modes in steel tube couplers. If the couplers do not meet industry standards or are made from low-quality materials, they may lack the necessary strength and durability, making failure more likely. To prevent these failure modes, it is crucial to ensure that the scaffolding design is appropriate for the intended load and usage. Regular inspections and maintenance should be carried out to identify any signs of wear, corrosion, or damage to the couplers. Proper training and education of personnel involved in the assembly and disassembly of scaffolding are also essential to ensure correct installation and alignment of the couplers. Using high-quality and corrosion-resistant couplers, as well as following manufacturer guidelines and industry best practices, can also help prevent the common failure modes of steel tube couplers in scaffolding.

Send your message to us

Parallel Thread Rebar Coupler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords