Detailed Product Description/

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.convenient scaffolding system

2.industrial buildings and civil buildings

Convenient Ring - Lock Scaffold Formwork For Industrial, Civil Buildings

Description:

Brief introduction

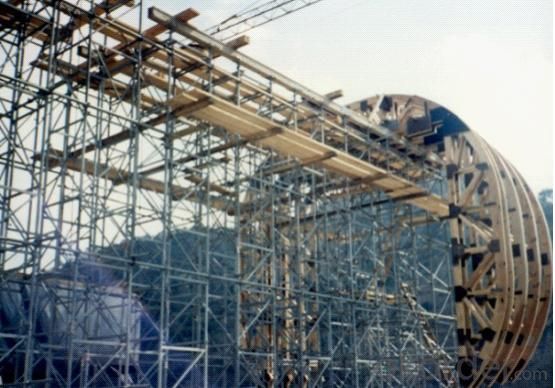

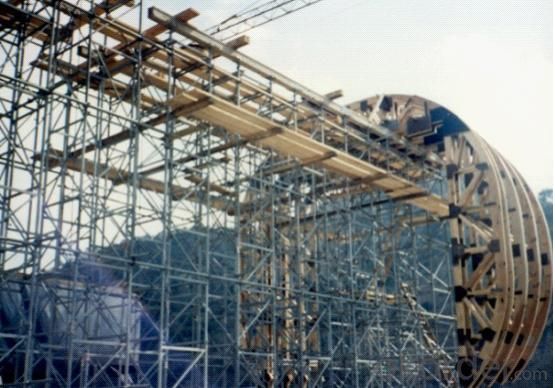

A convenient scaffolding system, especially for load-bearing support, its structure is simple and reasonable, its operation is easy and flexible, and the system is widely used in industrial buildings and civil buildings.

Competitive advantage

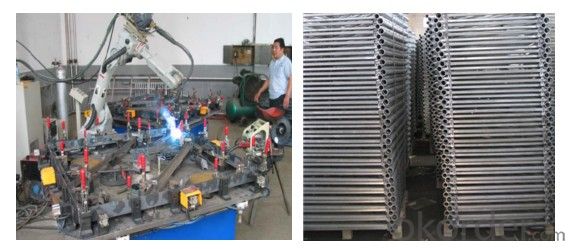

①. Product standardization, produce cost is lowered.

As the picture left shown, the standard is auto-welded; all the distance between cross plates of standards with different length is 500mm, which makes the auto-welded working method be easily achieved.

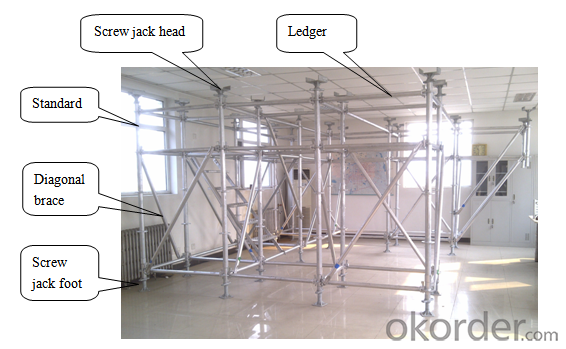

②. Spatial tower assembly guarantees high load-bearing capacity.

The main body of RL-scaffolding system is consisted of standard, ledger, diagonal ledger, and diagonal brace. The system forms a whole spatial frame structure that guarantees its high load-bearing capacity.

③.Smart joint design guarantees safe application and easy operation.

As the picture below shown, the “connect head” stuck in the position of cross plate with correct hole, then fix the pins tightly with a hammer, after that, you finish the whole connection work. The joint is safe and firmly.

Applications

- Q: What is the typical lifespan of steel tube couplers in scaffolding?

- The typical lifespan of steel tube couplers in scaffolding can vary depending on several factors such as usage, maintenance, and environmental conditions. However, with proper care and regular inspections, steel tube couplers can last for many years, often exceeding 10 to 15 years or more.

- Q: Can steel tube couplers be used in both tube and fitting scaffolding systems?

- Yes, steel tube couplers can be used in both tube and fitting scaffolding systems. Steel tube couplers are versatile and designed to connect steel tubes together securely. They are commonly used in various types of scaffolding systems, including tube and fitting scaffolding systems. These couplers are essential for connecting horizontal, vertical, and diagonal tubes, ensuring the stability and structural integrity of the scaffold. Whether it is a tube and fitting system or any other scaffolding system that uses steel tubes, steel tube couplers are compatible and can be used effectively.

- Q: Are steel tube couplers reusable or designed for single-use only?

- Steel tube couplers have been specifically engineered for reusability. These couplers are commonly employed in a wide range of applications, including scaffolding, construction, and engineering projects, to effectively join steel tubes together. They are manufactured using robust materials like steel and are adept at withstanding heavy loads while providing a dependable connection between tubes. The cost-effectiveness and practicality of steel tube couplers lie in their ability to be reused multiple times. Unlike certain other couplers or connectors that are intended for single-use only, steel tube couplers can be easily dismantled and reinstalled whenever necessary. This adaptability facilitates efficient assembly and disassembly of structures, making them particularly advantageous for temporary or adjustable installations. Additionally, the durability of steel tube couplers guarantees that they can endure repeated usage without compromising their performance or safety. This attribute is especially significant in industries wherein structures need to be frequently constructed and dismantled, or where adjustments and modifications are required. Nevertheless, it is crucial to emphasize the importance of proper inspection and maintenance when reusing steel tube couplers. Regular examinations must be carried out to identify any indications of wear, corrosion, or damage that could jeopardize their integrity. If any issues are detected, it is imperative to replace the couplers to ensure the safety of the structure. In conclusion, steel tube couplers have been designed with reusability in mind and can offer a secure and dependable connection between steel tubes. Their durability, flexibility, and cost-effectiveness render them an excellent choice for various applications that necessitate frequent assembly and disassembly of structures.

- Q: Can steel tube couplers be used in both indoor and outdoor scaffolding projects?

- Steel tube couplers offer a reliable and durable solution for connecting scaffolding tubes, making them a popular choice among construction professionals. These couplers can be used in both indoor and outdoor scaffolding projects, providing a strong and stable structure. They securely connect scaffolding tubes together, ensuring the safety of workers and the stability of the structure. Made from durable and weather-resistant materials, such as galvanized steel, these couplers are suitable for outdoor use. They can withstand harsh weather conditions, including rain, snow, and extreme temperatures, without rusting or deteriorating. This durability makes them ideal for outdoor scaffolding projects that require strength and reliability. In indoor settings, steel tube couplers are also commonly used. They find applications in building renovations, maintenance work, and other construction projects that take place indoors. These couplers provide a secure and stable connection between scaffolding tubes, ensuring the safety of workers and the stability of the structure. Overall, steel tube couplers are versatile and can be used in a wide range of scaffolding projects, both indoors and outdoors. Their reliable and durable nature makes them a preferred choice among construction professionals for securely connecting scaffolding tubes.

- Q: Are steel tube couplers compatible with scaffolding projects involving temporary roofs or canopies?

- Yes, steel tube couplers are compatible with scaffolding projects involving temporary roofs or canopies. Steel tube couplers are commonly used in scaffolding systems to connect and secure the tubes together, creating a stable and durable structure. These couplers are designed to provide a strong connection between the tubes, ensuring the scaffolding can support the weight of the temporary roof or canopy. Additionally, steel tube couplers are versatile and can be used in various configurations to meet the specific requirements of the project. Therefore, they are an ideal choice for scaffolding projects involving temporary roofs or canopies.

- Q: Are steel tube couplers resistant to extreme temperatures or weather conditions?

- Known for their durability and ability to withstand extreme temperatures and weather conditions, steel tube couplers are made from high-quality steel with excellent resistance to heat and cold. Their design ensures that they maintain strength and structural integrity even in the face of extreme temperature fluctuations, be it high heat or freezing cold. Moreover, steel tube couplers exhibit a high resistance to corrosion, rendering them suitable for use in diverse weather conditions such as rain, snow, and humidity. In summary, steel tube couplers are widely regarded as dependable and sturdy components capable of enduring the most severe environmental conditions.

- Q: How do steel tube couplers ensure the proper alignment of scaffolding tubes?

- The alignment of scaffolding tubes is ensured by the use of steel tube couplers, which securely connect the tubes together. These couplers are designed to fit over the ends of the tubes, creating a connection that is both strong and rigid. Typically constructed from high-quality steel, these couplers offer durability and reliability. One important feature of steel tube couplers is their ability to maintain the alignment of the scaffolding tubes. When properly tightened, the couplers securely hold the tubes in place, preventing any movement or rotation. This ensures that the scaffolding structure remains stable and safe for workers. In addition, steel tube couplers are designed with precision and accuracy in mind. They have a snug fit that minimizes any gaps between the tubes, which is crucial for maintaining the proper alignment. This ensures that the scaffolding structure remains level and even. Furthermore, steel tube couplers are often equipped with locking mechanisms or bolts that provide additional security for the connection between the tubes. These mechanisms prevent any accidental dislodging or loosening of the couplers, which could compromise the alignment of the scaffolding. Overall, steel tube couplers play a critical role in maintaining the proper alignment of scaffolding tubes. They create a strong and secure connection that minimizes any movement or rotation. With their precise fit and locking mechanisms, they contribute to the stability and safety of the scaffolding structure.

- Q: Are there any specific safety guidelines for using steel tube couplers in scaffolding?

- Steel tube couplers in scaffolding have specific safety guidelines that must be followed. To start, it is crucial to use couplers that are of high quality and meet the necessary standards. They should be manufactured properly and be suitable for the intended purpose. It is advisable to use couplers that have been tested and approved by relevant authorities or organizations. Next, it is essential to inspect the couplers before using them. This involves checking for any signs of damage, wear, or corrosion. If any defects are found, the couplers should be replaced immediately. Furthermore, it is important to secure the couplers to the scaffold tubes correctly. This can be achieved by fully tightening the bolts or clamps according to the manufacturer's instructions. Loose or inadequately secured couplers can lead to instability and pose a safety hazard. Moreover, when erecting scaffolding with steel tube couplers, it is vital to follow the manufacturer's guidelines and industry best practices. This includes ensuring that the scaffold is properly braced, level, and plumb, and using the correct number and type of couplers for adequate support and stability. Regular inspections and maintenance of the couplers and scaffolding are also necessary to ensure ongoing safety. This involves checking for any signs of damage, wear, or movement and promptly addressing any issues that arise. To summarize, the use of steel tube couplers in scaffolding requires adherence to specific safety guidelines. These include using high-quality couplers, inspecting them before use, securing them properly, following manufacturer's guidelines, conducting regular inspections and maintenance, and adhering to industry best practices. By following these guidelines, the risk of accidents or failures can be minimized, thereby ensuring a safe working environment for those utilizing the scaffolding.

- Q: Are steel tube couplers suitable for use in corrosive or chemical environments?

- Steel tube couplers are not appropriate for corrosive or chemical environments. When steel comes into contact with acids, bases, or saltwater, it is prone to corrosion. Over time, this corrosion weakens the steel, compromising its strength and structural integrity. To ensure safety and durability in corrosive or chemical environments, it is recommended to use couplers that are made from materials explicitly engineered to resist corrosion, such as stainless steel or plastic.

- Q: What are the common maintenance practices for steel tube couplers in scaffolding?

- The common maintenance practices for steel tube couplers in scaffolding include regular inspections for any signs of damage or wear, such as cracks or deformations. They should also be cleaned regularly to remove any dirt or debris that could compromise their functionality. Lubricating the couplers with a suitable lubricant can help to prevent rust and ensure smooth operation. Additionally, storing the couplers in a dry and well-ventilated area can help to prolong their lifespan and prevent corrosion.

Send your message to us

Detailed Product Description/

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords