Frame-Connected Scaffolding with Ideal Materials for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

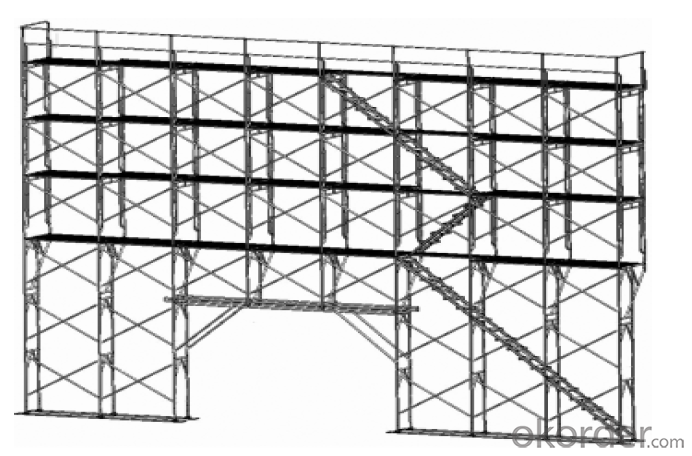

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

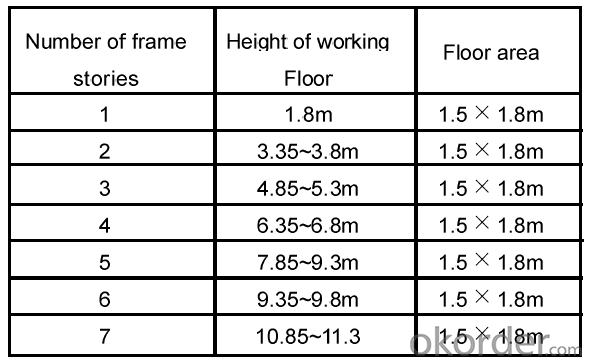

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: A uniform 300nt. scaffold is 8 meters long. it hangs from two ropes, one at ech end. A 700nt painter stands two meters from one end. What are the tensions in the two ropes?

- Let the tension in the two ropes are T1(near) T2(far) Newtons, =>T1+T2 = 300 + 700 = 1000 -----(i) The unit length weight of scaffold = 300/8 = 37.5 N By taking the torque at painter, =>T1 x 2 + [37.5 x 6] x 3 = T2 x 6 + [37.5 x 2] x 1 =>2T1 + 675 = 6T2 + 75 =>3T2 - T1 = 300 ------(ii) by (i) + (ii):- =>4T2 = 1300 =>T2 = 1300/4 = 325 N =>T1 = 675 N

- Q: Can steel tube couplers be used in scaffolding projects with limited access to lifting equipment?

- Yes, steel tube couplers can be used in scaffolding projects with limited access to lifting equipment. Steel tube couplers are commonly used to connect scaffolding tubes together, providing a secure and stable structure. These couplers do not require lifting equipment for installation, as they can be easily tightened by using a wrench or spanner. This makes them suitable for projects with limited access to lifting equipment, as they can be installed manually by workers on site. Additionally, steel tube couplers are known for their strength and durability, ensuring the safety and stability of the scaffolding structure.

- Q: Do you think it looks thuggy or trashy? I am not a fan of it and my 18 year old did this, I just found out!

- ive had both of these done when i was 13, and im 16 now and i still think they are pretty ******* awesome ! , so if this was your mom or something talking below your question... shut up !

- Q: What safety standards do steel tube couplers need to meet?

- Steel tube couplers, also called steel pipe connectors or fittings, are utilized in a wide range of applications, including construction, plumbing, and industrial settings, to connect steel tubes or pipes. To guarantee the safety and dependability of these connections, steel tube couplers must fulfill specific safety criteria. One of the primary safety criteria that steel tube couplers must satisfy involves meeting dimensional and mechanical requirements specified by international or national standards organizations. These requirements often encompass parameters such as the couplers' size, wall thickness, and length, as well as their mechanical properties like tensile strength, yield strength, and ductility. Alongside the dimensional and mechanical criteria, steel tube couplers must also meet performance standards. This entails their ability to withstand high loads, pressures, and vibrations without experiencing failure or leakage. For instance, in construction applications, steel tube couplers often endure heavy loads and forces, necessitating their capability to withstand these conditions without compromising the integrity of the connection. Furthermore, depending on the application, steel tube couplers may need to adhere to specific industry standards or certifications. In the oil and gas industry, for example, couplers used for pipeline connections may be required to meet standards such as API (American Petroleum Institute) or ASME (American Society of Mechanical Engineers) to ensure their suitability for the specific environment and conditions they will encounter. Moreover, safety standards for steel tube couplers generally mandate that they be manufactured using high-quality materials that resist corrosion, rust, and other forms of deterioration. This is crucial for preserving the structural strength and longevity of the connections. Additionally, it is essential for steel tube couplers to undergo thorough testing and inspection procedures to ensure compliance with safety standards. These procedures may involve various methods, including destructive and non-destructive testing, such as tensile testing, pressure testing, visual inspection, and ultrasonic testing. Overall, the safety standards governing steel tube couplers encompass multiple aspects, including dimensional and mechanical requirements, performance specifications, industry standards, material quality, and rigorous testing procedures. By adhering to these standards, steel tube couplers can provide dependable and secure connections, thereby ensuring the overall safety and integrity of the structures or systems in which they are employed.

- Q: How do steel tube couplers ensure the stability and rigidity of scaffolding structures during use?

- Steel tube couplers ensure the stability and rigidity of scaffolding structures during use by providing a secure connection between the steel tubes. These couplers are designed to grip the tubes tightly, preventing any movement or slippage. This ensures that the scaffolding remains stable and rigid, even when subjected to various loads and forces. The strong and reliable connection created by the couplers enhances the overall structural integrity of the scaffolding, ensuring the safety of workers and the stability of the platform.

- Q: How do you ensure proper stability when using steel tube couplers in confined spaces scaffolding?

- When using steel tube couplers in confined spaces scaffolding, there are several measures that can be taken to ensure proper stability: 1. Adequate spacing: Ensure that the steel tube couplers are spaced at regular intervals along the scaffolding structure. This will help distribute the load evenly and prevent any weak points. 2. Secure connections: Make sure that the steel tube couplers are properly tightened and secured to the scaffolding tubes. Loose connections can compromise stability and increase the risk of accidents. 3. Proper alignment: Ensure that the scaffolding tubes are aligned correctly and inserted fully into the steel tube couplers. Misalignment can lead to weak connections and reduced stability. 4. Use of diagonal bracing: Incorporate diagonal bracing within the scaffolding structure to provide additional stability. These braces help to distribute the load more evenly and prevent excessive movement. 5. Regular inspections: Regularly inspect the steel tube couplers and scaffolding structure for any signs of damage or wear. Replace any damaged or worn-out components immediately to maintain the stability and safety of the scaffolding. 6. Ensure proper weight distribution: Avoid placing excessive weight on any single section of the scaffolding. Distribute the load evenly across the structure to prevent overloading and maintain stability. 7. Follow manufacturer guidelines: Always follow the manufacturer's instructions and guidelines when using steel tube couplers in confined spaces scaffolding. This will ensure that you are using the couplers correctly and maximizing their stability. By following these guidelines, you can ensure proper stability when using steel tube couplers in confined spaces scaffolding, minimizing the risk of accidents and creating a safe working environment.

- Q: Can steel tube couplers be used in scaffolding projects with limited foundation support?

- Steel tube couplers are suitable for scaffolding projects with limited foundation support. They are extensively used in scaffolding systems to link steel tubes, creating a robust and secure structure. These couplers are designed to withstand heavy loads and are commonly employed in construction projects where safety is of utmost importance. In projects with limited foundation support, steel tube couplers offer numerous advantages. They enable versatile and flexible scaffolding designs as they can be easily adjusted and repositioned to accommodate various ground conditions. This flexibility aids in distributing the load across multiple support points, thereby minimizing the impact on the limited foundation support available. Moreover, steel tube couplers are renowned for their durability and strength. They establish a stable and secure connection among scaffolding components, ensuring the safety of workers and materials. This aspect is particularly vital in projects with limited foundation support as a reliable and sturdy scaffolding structure is crucial. Nevertheless, it is always advisable to seek advice from a structural engineer or scaffolding expert before using steel tube couplers in projects with limited foundation support. They can evaluate the specific site conditions and offer guidance on the appropriate design and utilization of scaffolding systems to ensure compliance with local regulations and guarantee safety.

- Q: Are steel tube couplers suitable for scaffolding projects with complex or intricate designs?

- Yes, steel tube couplers are suitable for scaffolding projects with complex or intricate designs. Steel tube couplers offer a versatile and flexible solution for joining scaffolding tubes in various angles and configurations, making them ideal for projects that require complex or intricate designs. These couplers provide reliable and secure connections, allowing scaffolding structures to be built with precision and stability, even in challenging or unique layouts.

- Q: what does the terminology 'Scaffolding principle' mean, refering to psychology?

- One sets of facts depend upon another being true. If the premise is only theory, then the conjecture which is supported by it is flimsy indeed.

- Q: What is the typical weight limit for steel tube couplers in scaffolding?

- The typical weight limit for steel tube couplers in scaffolding varies depending on different factors such as the specific type of coupler being used, the manufacturer's specifications, and the intended application. However, as a general guideline, most steel tube couplers used in scaffolding systems are designed to support loads ranging from 500 to 1000 kilograms (1100 to 2200 pounds) per coupler. It is crucial to consult the manufacturer's documentation or the scaffolding engineer to determine the exact weight limit for a particular type of steel tube coupler to ensure safe and proper usage.

Send your message to us

Frame-Connected Scaffolding with Ideal Materials for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords