Frame-Connected Scaffolding for Civil Construction and Industrial

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

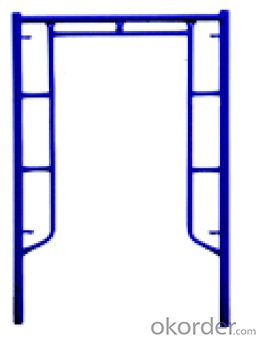

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

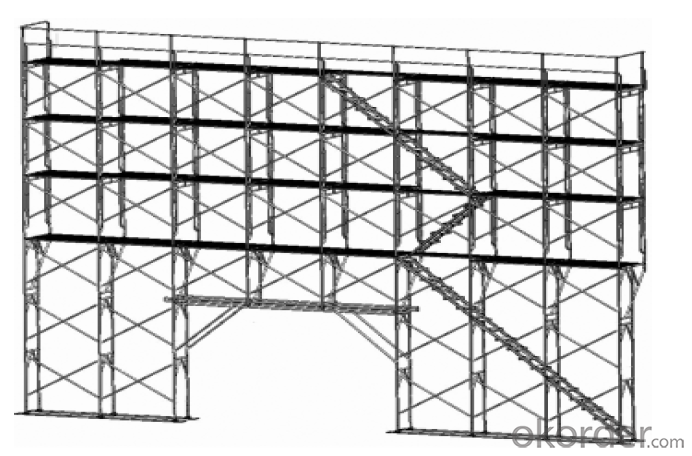

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

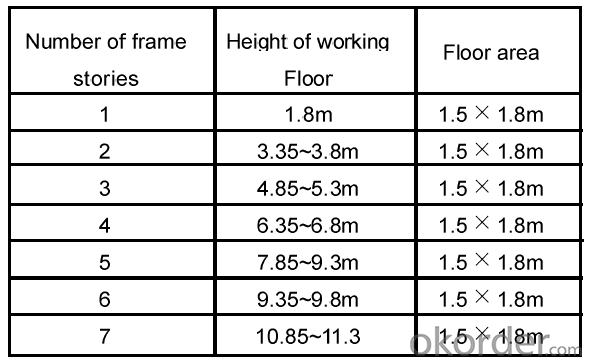

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Construction construction fastener type steel pipe scaffolding safety technical specifications of the latest version of what is

- 2 Since the intention to paste the wall, then the external walls need to chisel and then brush the cement mortar to shop

- Q: What is the purpose of using steel tube couplers in scaffolding?

- Steel tube couplers are utilized in scaffolding to securely connect and join the diverse components of the scaffold structure. These couplers are specifically designed to establish a robust and dependable connection between the tubes, thereby ensuring stability and safety for the workers utilizing the scaffolding. The implementation of couplers enables the scaffolding to be conveniently assembled, disassembled, and altered, thereby allowing for flexibility and adaptability in construction projects. Additionally, these steel tube couplers possess corrosion resistance and exceptional load-bearing capabilities, rendering them suitable for a wide range of construction applications. In essence, the primary objective of utilizing steel tube couplers in scaffolding is to establish a stable and secure structure that effectively supports both workers and materials throughout the construction process.

- Q: What are the maximum heights that can be achieved using steel tube couplers?

- The maximum heights that can be achieved using steel tube couplers depend on various factors such as the size and strength of the steel tubes, the design and stability of the structure, and the specific application or load requirements. Steel tube couplers are commonly used in construction and scaffolding projects to join steel tubes together and create a stable framework. The height that can be achieved using steel tube couplers is determined by the load-bearing capacity of the couplers, the strength of the steel tubes, and the overall stability of the structure. In general, steel tube couplers are designed to support a certain amount of weight and provide stability to the structure. The maximum height that can be achieved using steel tube couplers will depend on the load capacity of the couplers and the strength of the steel tubes. It is important to consult engineering guidelines and specifications to ensure that the maximum height is within the safe limits set by industry standards and regulations. Additionally, other factors such as wind loads, seismic conditions, and safety considerations may also play a role in determining the maximum height that can be achieved using steel tube couplers. Engineering calculations and structural analysis should be conducted to assess the stability and integrity of the structure at higher heights. Ultimately, the maximum height achievable using steel tube couplers will vary depending on the specific application, design, and engineering considerations. It is important to work with experienced professionals and adhere to industry guidelines to ensure the safety and stability of the structure.

- Q: Anyone know how much they are in Public Image? :)Try not to put a stupid answer. :) ta.

- Try not to put a stupid question. Call the place and find out. Customer service is free.

- Q: Can steel tube couplers be used in scaffolding projects that require temporary roofing or weather protection?

- Steel tube couplers are an excellent choice for scaffolding projects that necessitate temporary roofing or weather protection. They are frequently utilized in scaffolding to connect and secure steel tubes, resulting in robust and dependable connections. This makes them suitable for supporting temporary roofs or structures designed to shield against inclement weather conditions. When employed in scaffolding projects for temporary roofing or weather protection, steel tube couplers can establish a stable and secure framework. They can be used to link steel tubes and form the primary structure of the temporary roof or weather protection, ensuring its ability to withstand varying weather conditions. Furthermore, steel tube couplers possess versatility and ease of adjustment or disassembly, making them particularly well-suited for temporary structures. They facilitate swift installation and dismantling, which is often essential for projects requiring temporary roofing or weather protection. Overall, steel tube couplers are a fitting choice for scaffolding projects that necessitate temporary roofing or weather protection. They offer robust connections, versatility, and ease of adjustment or disassembly, rendering them a reliable and efficient solution for such endeavors.

- Q: How do you calculate the required number of steel tube couplers for a specific scaffolding project?

- To determine the necessary quantity of steel tube couplers for a particular scaffolding undertaking, several crucial factors must be taken into account. Initially, you must ascertain the total length of tubes to be utilized in the project. This can be achieved by measuring the gaps between each platform or level of the scaffold, as well as the vertical height required. Subsequently, you need to identify the types of connections that will be established using the steel tube couplers. For instance, if you plan to connect two tubes in a straight line, one coupler will suffice. However, if you intend to create a corner or an intersection, multiple couplers may be necessary to ensure stability and safety. In addition, the load-bearing capacity of the scaffolding must be considered as this will dictate the spacing and quantity of couplers required. Referring to the manufacturer's guidelines or industry standards for the specific load ratings of the couplers and calculating the maximum load capacity of each connection point will aid in determining the number of couplers needed to evenly distribute the load throughout the structure. Finally, any additional factors such as safety regulations or local building codes that specify specific requirements for the number of couplers needed should be taken into account. By thoroughly considering these factors, you will be able to accurately calculate the requisite number of steel tube couplers for your particular scaffolding project. It is always advisable to consult a professional engineer or scaffolding specialist to ensure compliance with safety standards and regulations.

- Q: How do steel tube couplers ensure a secure connection between tubes?

- Steel tube couplers ensure a secure connection between tubes through their design and mechanical properties. Firstly, these couplers are designed to provide a precise fit between two tubes, ensuring that there is minimal movement or play between them. This tight fit helps to maintain the structural integrity of the connection. Furthermore, steel tube couplers often feature internal teeth or grooves that grip onto the surface of the tubes. These teeth create a strong frictional force that prevents the tubes from sliding or rotating relative to each other. This gripping action enhances the stability and security of the connection, particularly in applications where the tubes are subjected to axial or torsional loads. In addition to the gripping mechanism, steel tube couplers are typically made from high-strength steel materials. This choice of material ensures that the couplers themselves can withstand significant forces and stresses without deforming or failing. By using strong and durable materials, the couplers provide a reliable and robust connection between the tubes, even under demanding conditions. Overall, steel tube couplers ensure a secure connection between tubes by offering a precise fit, employing a gripping mechanism, and utilizing high-strength materials. These features work together to create a connection that is resistant to movement, rotation, and failure, providing confidence in the structural integrity of the joined tubes.

- Q: Are steel tube couplers suitable for scaffolding projects with uneven or sloping surfaces?

- No, steel tube couplers are not suitable for scaffolding projects with uneven or sloping surfaces. The uneven or sloping surfaces can affect the stability and safety of the scaffolding structure, making it difficult to securely connect the steel tube couplers. In such cases, alternative scaffolding methods or adjustable couplers specifically designed for uneven or sloping surfaces should be used.

- Q: How do steel tube couplers ensure the safety and stability of scaffolding platforms or work areas?

- Steel tube couplers ensure the safety and stability of scaffolding platforms or work areas by providing a secure connection between the tubes. These couplers are designed to grip the tubes tightly, preventing any movement or slippage. This ensures that the scaffolding structure remains sturdy and stable, reducing the risks of accidents or collapse. Additionally, the use of steel tube couplers allows for easy adjustment and reconfiguration of the scaffolding system, providing flexibility while maintaining a high level of safety.

- Q: What are the typical weight capacities of steel tube couplers in scaffolding applications?

- The weight capacities of steel tube couplers in scaffolding applications can differ based on the coupler's specific type and design. However, in general, steel tube couplers used in scaffolding are engineered and tested to safely support heavy loads. Take, for instance, a standard double coupler, which is commonly employed to connect two scaffold tubes at right angles. Typically, it can bear a weight of approximately 5,000 to 6,000 pounds (2,268 to 2,722 kilograms) without any risk of failure or collapse. Likewise, other kinds of steel tube couplers, like swivel couplers and beam clamps, also possess substantial weight capacities to ensure the stability and safety of the scaffolding system. Swivel couplers, designed to connect two scaffold tubes at any angle, usually have weight capacities ranging from 4,000 to 6,000 pounds (1,814 to 2,722 kilograms). Beam clamps, which are utilized to attach scaffold tubes to steel beams, can possess weight capacities ranging from 3,000 to 6,000 pounds (1,361 to 2,722 kilograms) or potentially more, depending on the specific model and design. It is important to recognize that these weight capacities are general guidelines and may differ due to factors such as the coupler's quality, the condition of the scaffold tubes, and the overall design and arrangement of the scaffolding system. It is always advisable to consult the manufacturer's specifications and guidelines for accurate weight capacity information and to ensure the safe and proper utilization of steel tube couplers in scaffolding applications.

Send your message to us

Frame-Connected Scaffolding for Civil Construction and Industrial

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches