Frame-Connected High Qulity and Convenient Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

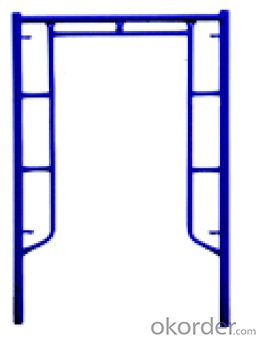

1. Structure of Frame-Connected Scaffolding

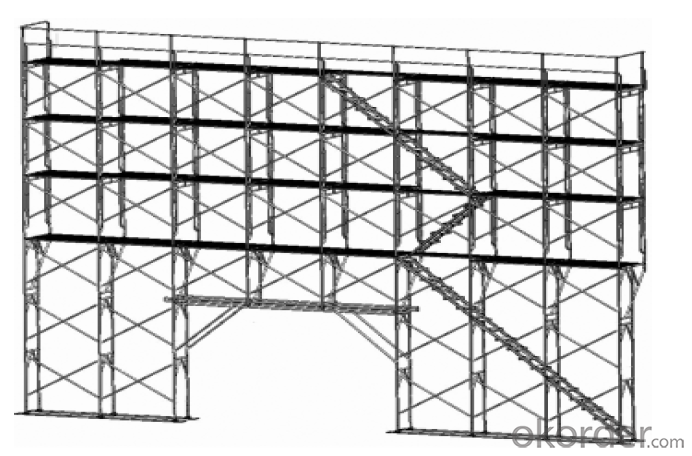

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

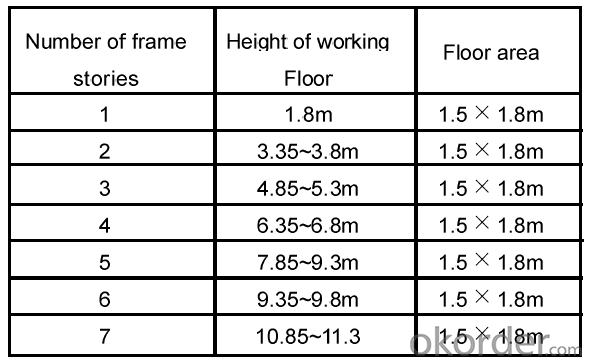

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel tube couplers be used for scaffolding systems with high wind loads?

- Yes, steel tube couplers can be used for scaffolding systems with high wind loads. Steel tube couplers are strong and durable, making them capable of withstanding high wind forces. However, it is important to ensure that the scaffolding system is properly designed and erected by professionals to account for the specific wind load requirements.

- Q: Can steel tube couplers be used in scaffolding systems that need to accommodate special access requirements?

- Indeed, steel tube couplers are capable of being utilized in scaffolding systems that necessitate the accommodation of distinctive access prerequisites. These versatile steel tube couplers possess the ability to connect scaffolding tubes at diverse angles and positions, thereby enabling the creation of customized scaffolding structures. This adaptability renders them suitable for scaffolding systems that require adjustment to cater to exceptional access requirements, including facilitating entry into irregularly shaped or difficult-to-reach areas. Moreover, the strength and dependability of steel tube couplers are well-regarded, guaranteeing the stability and safety of the scaffolding system, even when confronted with special access demands.

- Q: Can steel tube couplers be used in confined spaces scaffolding projects?

- Yes, steel tube couplers can be used in confined spaces scaffolding projects. Steel tube couplers are commonly used in scaffolding systems to securely connect tubes and provide stability. They are versatile and can be used in various project environments, including confined spaces, as long as they are properly installed and meet safety regulations.

- Q: Can steel tube couplers be used for scaffolding projects that require frequent load testing?

- Yes, steel tube couplers can be used for scaffolding projects that require frequent load testing. Steel tube couplers are commonly used in construction and scaffolding industries to connect steel tubes and provide a secure and rigid connection. They are designed to withstand heavy loads and provide a stable structure for scaffolding systems. When it comes to load testing, steel tube couplers are tested and certified for their load-bearing capacity. This ensures that they can support the intended loads during scaffolding projects. Some couplers are specifically designed for heavy-duty applications and are capable of withstanding even higher loads. In scaffolding projects that require frequent load testing, it is important to ensure that the steel tube couplers used are properly rated and certified for the expected loads. Regular inspections and load tests should be conducted to ensure the safety and integrity of the scaffolding system. This involves applying loads to the scaffolding to verify its strength and stability, as well as checking the condition of the couplers and other components. Overall, steel tube couplers are suitable for scaffolding projects that require frequent load testing, as long as they are properly certified and inspected. It is essential to follow the manufacturer's guidelines and industry standards to ensure the safe and efficient use of steel tube couplers in such projects.

- Q: How do steel tube couplers compare to other types of scaffolding connectors?

- Steel tube couplers are generally considered to be stronger and more durable compared to other types of scaffolding connectors. They provide a secure and reliable connection between scaffolding tubes, ensuring stability and safety. Additionally, steel tube couplers are versatile and can be used in various scaffolding configurations, making them a preferred choice for many construction projects.

- Q: Are steel tube couplers suitable for outdoor scaffolding applications?

- Yes, steel tube couplers are suitable for outdoor scaffolding applications. Steel is a durable and weather-resistant material, making it ideal for use in outdoor environments. Couplers provide a strong and secure connection between steel tubes, ensuring the stability and safety of the scaffolding structure.

- Q: How do steel tube couplers contribute to the overall cost-effectiveness of scaffolding systems?

- Several factors contribute to the overall cost-effectiveness of scaffolding systems, and steel tube couplers play a crucial role in this regard. To begin with, the durability and longevity of steel tube couplers are remarkable. Crafted from top-notch steel, they offer unparalleled strength and stability to the scaffolding structure. This robustness ensures that the system can withstand heavy loads and endure harsh weather conditions, thereby reducing the need for frequent repairs or replacements. As a result, maintenance and replacement costs associated with scaffolding systems are considerably minimized, making them more cost-effective in the long run. Moreover, the versatility of steel tube couplers allows for easy adjustments and reconfigurations to suit the specific requirements of different projects. This flexibility eliminates the necessity of purchasing additional components or materials, resulting in significant time and cost savings. It facilitates swift assembly and disassembly of the scaffolding system, thereby reducing labor costs and increasing productivity on construction sites. Another significant aspect contributing to cost-effectiveness is the ability to reuse steel tube couplers. These couplers can be effortlessly dismantled and repurposed in various projects, thereby reducing overall material costs. This reusability not only saves money but also reduces waste and promotes sustainability within the construction industry. Furthermore, steel tube couplers ensure a secure and sturdy connection between scaffold tubes, guaranteeing the safety of workers on-site. By minimizing the risk of accidents and injuries, scaffolding systems equipped with steel tube couplers help avoid potential legal liabilities and associated costs. In conclusion, the utilization of steel tube couplers in scaffolding systems yields numerous cost-effective benefits. These include durability, versatility, reusability, and safety. With reduced maintenance and replacement costs, saved time and labor, enhanced sustainability, and mitigated legal liabilities, incorporating steel tube couplers is undoubtedly a wise investment that leads to long-term cost savings.

- Q: Do you have to be a certain age to get an scaffold ear piercing?

- Legally? Not typically (some states have limits like 13 or 14 for body piercing in general last I checked, but that was years ago). But if you're under 18, you will need parental consent. This is a US answer btw, if you live somewhere else, answers will vary. But anywhere you go, piercers can and do set their own age limits within the confines of the law. The easiest way to find out for sure is to ring up a few shops and ask. Oh, personal warning. Scaffolding/Industrial is a really difficult piercing to heal. Extremely prone to problems like hypertrophic scarring and long healing times (mine took about a year and a half; I had problems with it). Not telling you not to get the piercing, just that this is something to be aware of before hand.

- Q: what is the job description of a certified saudi aramco scaffolding supervisor?

- Scaffolding work is a job of maintenance, so it only means that your work description is maintenance supervisor. ...

- Q: Are steel tube couplers suitable for scaffolding projects requiring frequent reconfiguration or customization?

- Yes, steel tube couplers are suitable for scaffolding projects requiring frequent reconfiguration or customization. Steel tube couplers are widely used in the construction industry for their versatility and durability. They provide a secure and reliable connection between scaffolding tubes, allowing for easy assembly, disassembly, and reconfiguration of scaffolding structures. Additionally, steel tube couplers can be adjusted and tightened as needed, making them an ideal choice for scaffolding projects that require frequent changes or customization. Their strength and stability ensure the safety of workers and the stability of the scaffolding system, even with frequent reconfiguration. Overall, steel tube couplers are a practical and reliable option for scaffolding projects that require flexibility and adaptability.

Send your message to us

Frame-Connected High Qulity and Convenient Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches