Frame Connected Scaffolding of Easy and Fast Operation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

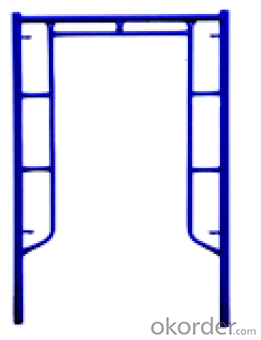

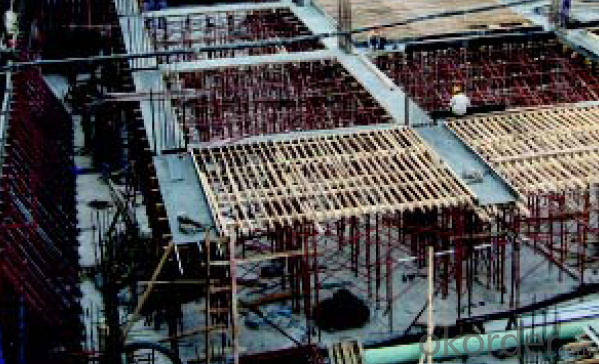

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Images

4. Specification

Maximum breaking load: 22.2t

Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How do steel tube couplers attach to scaffolding tubes?

- Steel tube couplers attach to scaffolding tubes by being slid over the end of the tube and secured in place using a tightening mechanism. The coupler typically consists of two parts - a sleeve and a wedge. The sleeve is a hollow cylindrical metal component that fits snugly over the end of the tube, while the wedge is a wedge-shaped piece that is inserted into the sleeve. To attach the coupler, the sleeve is first placed onto the tube, ensuring that it is positioned correctly and aligned with the desired angle. The wedge is then inserted into the sleeve, with the angled side facing towards the tube. As the wedge is pushed into the sleeve, it creates a tight grip on the tube, effectively locking the coupler in place. Once the coupler is attached, it provides a secure connection between two scaffolding tubes, allowing them to be joined together to form the desired structure. The tight grip of the coupler ensures stability and strength, enabling the scaffolding to support the weight of workers and materials safely. It is important to note that the installation of steel tube couplers should be carried out by trained and experienced scaffolders, who have a thorough understanding of the correct procedures and safety regulations. Proper installation and regular inspections are essential to ensure the integrity of the scaffolding structure and prevent any accidents or failures.

- Q: Its been up for 8 months! He hasn't been on the job site in over 6 months. He said he wasn't coming over today to remove scaffolding because the MHIC advised him to seek counsel. What does getting a lawyer have to do with getting his tools? What recourse do we have to get his property off our property? We already sent him a certified letter to remove the items. Does it become considered abandoned at some point?

- after 30 days of him receiving the letter, if he does not come get his materials they are now yours.(in my area you should check a little more to make sure you area has the same rules) They are technically yours. I'd try to sell them, depending on if they are in good shape, you can get quite a bit of good money for them. You also can send another cerified letter to contractor saying that as of [DATE] you are now charging [AMOUNT OF MONEY] per day to hold them for [CONTRACTOR NAME/COMPANY].

- Q: What are the common materials used for manufacturing steel tube couplers?

- The common materials used for manufacturing steel tube couplers are stainless steel, carbon steel, and alloy steel.

- Q: What are the load-bearing capacities of steel tube couplers?

- The load-bearing capacities of steel tube couplers vary depending on various factors such as the size, type, and specific design of the coupler. It is crucial to refer to the manufacturer's specifications and guidelines for accurate information on load-bearing capacities.

- Q: Are steel tube couplers compatible with scaffolding systems using different tube lengths?

- Yes, steel tube couplers are compatible with scaffolding systems using different tube lengths. Steel tube couplers are designed to connect scaffolding tubes and can accommodate various tube lengths, allowing for versatility and adaptability in scaffolding systems.

- Q: How do steel tube couplers accommodate different angles or connections in scaffolding systems with complex or intricate designs?

- Steel tube couplers accommodate different angles or connections in scaffolding systems with complex or intricate designs by providing a versatile and secure connection point. These couplers are capable of rotation, allowing them to adjust to various angles or connections, ensuring stability and flexibility in the scaffolding system. Additionally, the strong and durable nature of steel enables the couplers to handle the weight and load of the structure, making them reliable components for accommodating different angles or connections in complex scaffolding designs.

- Q: Can steel tube couplers be used for scaffolding structures that need to provide access to remote or difficult-to-reach areas?

- Scaffolding structures requiring access to remote or hard-to-reach areas can indeed utilize steel tube couplers. These couplers, commonly employed in scaffolding systems, facilitate the connection between tubes and establish a stable and secure structure. Their versatility allows for various configurations to meet diverse requirements, including accessing remote or difficult-to-reach areas. The utilization of steel tube couplers ensures a robust and trustworthy connection between scaffolding tubes, guaranteeing the stability and safety of the structure. Designed to withstand substantial loads, these couplers exhibit excellent resistance to corrosion and adverse weather conditions, rendering them suitable for challenging environments. Through the implementation of steel tube couplers, scaffolding structures can be conveniently assembled and disassembled, enabling swift setup and efficient access to remote or difficult-to-reach areas. These couplers offer flexibility in adjusting the height and configuration of the scaffolding to accommodate different terrains and obstacles. Furthermore, steel tube couplers are widely accessible and relatively cost-effective, making them an economical solution for scaffolding structures. They are also compatible with various other scaffolding components, allowing for customization and versatility in designing the scaffolding system. To summarize, steel tube couplers are an appropriate choice for scaffolding structures that require access to remote or difficult-to-reach areas. Their attributes of strength, stability, and flexibility make them an exceptional option for such applications.

- Q: Are there any specific guidelines for the safe use of steel tube couplers in scaffolding near electrical or hazardous areas?

- Yes, there are specific guidelines for the safe use of steel tube couplers in scaffolding near electrical or hazardous areas. When working in such environments, it is crucial to follow these guidelines to minimize the risk of accidents and ensure the safety of workers. 1. Risk Assessment: Before starting any work in an electrical or hazardous area, a thorough risk assessment must be conducted. Identify potential hazards, such as live electrical wires or flammable materials, and plan accordingly. 2. Qualified Personnel: Only trained and competent personnel should be allowed to work in these areas. They should have a good understanding of the potential risks and appropriate safety measures. 3. Isolation and Lockout/Tagout: If possible, electrical systems or equipment in the vicinity should be isolated and locked out or tagged out to prevent accidental activation during scaffold erection or dismantling. 4. Non-Conductive Scaffold Tubes: Consider using non-conductive scaffold tubes to reduce the risk of electrical shocks. Non-metallic or fiberglass scaffolding may be suitable in such situations. 5. Insulation: If non-conductive tubes are not available, ensure that metal scaffold tubes are adequately insulated. This can be achieved by using insulating sleeves or caps on exposed ends to prevent contact with live electrical sources. 6. Distance: Maintain a safe distance between scaffold tubes and any electrical or hazardous equipment. Follow local regulations or industry standards to determine the minimum distance required. 7. Grounding: If the scaffolding is required to be grounded, ensure proper grounding techniques are used to prevent the buildup of static electricity or electrostatic discharge. 8. Training and Awareness: All personnel working in the area should receive appropriate training on the potential hazards, emergency procedures, and safe practices. Regular safety meetings or toolbox talks can help reinforce these guidelines. 9. PPE: Personal Protective Equipment (PPE) should be provided and worn by all workers. This may include non-conductive gloves, safety helmets, eye protection, and footwear with electrical insulation. 10. Regular Inspection: Regularly inspect the scaffolding and couplers for any signs of damage or wear. Replace any defective or damaged components immediately. It is important to note that these guidelines may vary depending on local regulations and industry standards. Always consult relevant authorities, such as occupational health and safety agencies or professional scaffolding organizations, to ensure compliance with the specific requirements of your area.

- Q: What are the advantages of using steel tube couplers in scaffolding?

- There are several advantages of using steel tube couplers in scaffolding: 1. Strength and Durability: Steel tube couplers are made from high-grade steel, which provides exceptional strength and durability. They can withstand heavy loads and adverse weather conditions, making them ideal for construction projects that require sturdy scaffolding. 2. Versatility: Steel tube couplers can be used with a wide range of scaffold tubes, allowing for flexible configurations and easy assembly. This versatility makes them suitable for various construction applications, such as building maintenance, renovations, and infrastructure projects. 3. Safety: Steel tube couplers provide a secure and reliable connection between scaffold tubes, ensuring the stability and safety of the scaffolding structure. They are designed to prevent slippage or disconnection, reducing the risk of accidents and injuries. 4. Cost-effectiveness: Steel tube couplers are a cost-effective solution for scaffolding needs. They are relatively inexpensive compared to other scaffolding systems, and their durability ensures a longer lifespan, reducing the need for frequent replacements or repairs. 5. Easy Installation and Dismantling: Steel tube couplers are easy to install and dismantle, saving time and effort during construction projects. They do not require specialized tools or skills, making them accessible to a wide range of workers. 6. Compatibility: Steel tube couplers are compatible with various scaffolding accessories, such as platforms, boards, and guardrails. This compatibility allows for the customization and adaptation of scaffolding systems to meet specific project requirements. 7. Reduced Weight: Compared to traditional scaffolding systems, steel tube couplers are lightweight, which makes them easier to transport and handle. This advantage is particularly beneficial for projects that require frequent mobility or access to confined spaces. In summary, the advantages of using steel tube couplers in scaffolding include their strength, durability, versatility, safety, cost-effectiveness, ease of installation, compatibility with accessories, and reduced weight. These benefits make steel tube couplers an excellent choice for construction projects that require reliable and efficient scaffolding solutions.

- Q: Can steel tube couplers be easily adjusted or removed from scaffolding tubes?

- Yes, steel tube couplers can be easily adjusted or removed from scaffolding tubes. These couplers are designed to provide a strong and secure connection between two scaffolding tubes, but they can also be easily adjusted or removed when needed. They are typically made with a bolt and nut mechanism, which allows for quick and easy adjustment or removal. By loosening the nut, the coupler can be adjusted to the desired position or completely removed from the scaffolding tube. This flexibility is particularly useful when scaffolding structures need to be modified or dismantled. Overall, steel tube couplers offer both strength and versatility in scaffolding systems.

Send your message to us

Frame Connected Scaffolding of Easy and Fast Operation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords