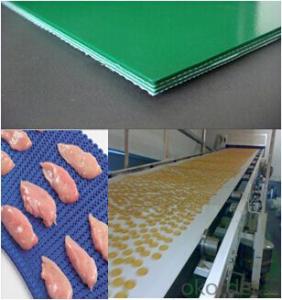

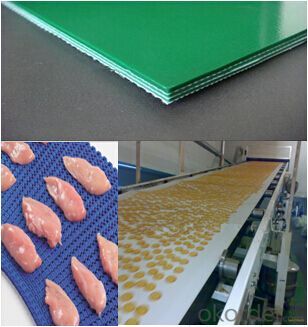

Green/White PVC/PU Conveyor Belt Used in Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green/White PVC/PU Conveyor Belt Used in Food Industry

Product Description:

Anti-static and tearing resistant

Abrasion and oil/heat/fire resistant

Working temperature ranges from -10 to 80Deg.C

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

Product Pictures:

- Q: Rubber soaked with hot water will not come out harmful substances?

- Chloroprene rubber is electrical insulation, cold resistant performance is poor, rubber is not stable in storage. Neoprene is widely used, such as the manufacture of transport belts and belts, wires and cables, and the manufacture of oil resistant hoses, gaskets, and chemical resistant equipment linings.

- Q: Process for producing rubber products

- In the production process of rubber products, the process of making various shapes and sizes is made by using a calender or an extruder, which is called forming. Forming methods are1. rolling formingThe utility model is suitable for making simple sheet and plate shaped articles. It is a method of pressing compound rubber into a certain shape and a certain size of film by calender. It is called calendering forming. Some rubber products, such as tires, adhesive tape, hose and other textile fiber materials, must be coated with a thin layer of glue on the fiber, also known as glue or glue, the process of gluing is generally completed on the calender. Fiber material needs drying and dipping drying before calendering. The purpose is to reduce moisture content of fiber material, avoid evaporation and foaming, and increase the temperature of fiber material, so as to ensure the quality of calendering process. Dipping is a necessary process before cementing. The purpose is to improve the bonding property of fiber and rubber.2. extrusion moldingFor more complex rubber products, such as tyres, tread, hose, and wire surface coating, shall be made by extrusion molding. It is a method of continuous molding with a certain plastic compound into the extruder's hopper, the extrusion of the screw under the internal screw, and through a variety of dies, also known as the templates. Before extrusion, the material must be preheated to make the material soft and easy to extrude so as to obtain a smooth and accurate rubber product.3. moldingIt can also be used to make some rubber products with complex shapes, such as leather bowl and sealing ring. The rubber material is placed in the mold and shaped by heating.

- Q: Why do rubber products Blister?

- A lot of reasons, but the main factors are: 1) there are 2 water) mixed rubber Mooney viscosity high fluidity of the compound 3) poor curing pressure lowFrom what you say without adding mold agent foaming phenomenon is more obvious in terms of liquidity, the reason may not glue a problem.

- Q: What's the difference between silicone rubber and 703.704 glue?

- 704, temperature range of -50-250, better temperature effect, mainly used for sealing electric heating devices; electric plug sealing; instrument, instrument bonding and sealing.

- Q: How does the rubber part of the watch become yellow?

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air.

- Q: UV glue can glue rubber products?

- If you want to completely recover, do not see the crack, in addition to professional factories, individuals can not reach this technology for the time being

- Q: How can rubber products prevent fading?

- Light and white rubber products are prone to yellowing in the course of use and storage, thus affecting appearance and quality, resulting in various economic disputes and irreversible losses.

- Q: The action of various ingredients in rubber formula

- Curing system: vulcanizing agent, accelerator, active agent, anti coke agent,

- Q: Why does rubber stink?

- Because of the original gum problem, such as PU or polyurethane will have a foul smell.Highly elastic polymer material with reversible deformation of rubber. It is elastic at room temperature and can produce great deformation under very little external force. It can be restored to original state after removing external force. Rubber is completely amorphous polymer, its glass transition temperature (T, g) is low, the molecular weight is often large, more than hundreds of thousands.

- Q: How is the temperature range of rubber determined?

- Rubber is based on rubber molecular structure and molecular weight as well as microscopic view to determine temperature range!

Send your message to us

Green/White PVC/PU Conveyor Belt Used in Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords