Custom Rubber Seal Strip for Door&Window Fireproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Custom Rubber Seal Strip for Door&Window Fireproof :

1. Brief Description of Custom Rubber Seal Strip for Door&Window Fireproof

Our solid rubber profiles include rubber u channel, glazing rubber, rubber cord, rubber tube, rubber strip, rubber flocking, trim seal, door and window seals, etc.

The types of rubber we used in making rubber profiles include NBR (Buna-N), EPDM, Neoprene (CR), Silicone and Viton.

EPDM 65+/-5 is the most popular material.

2. Main Features of Custom Rubber Seal Strip for Door&Window Fireproof

1).Ozone and chemical resistance

2).High temperature resistance

3). Excellent weather and water resistance

4).Anti-aging, anti-radiation, good flexibility, good elasticity

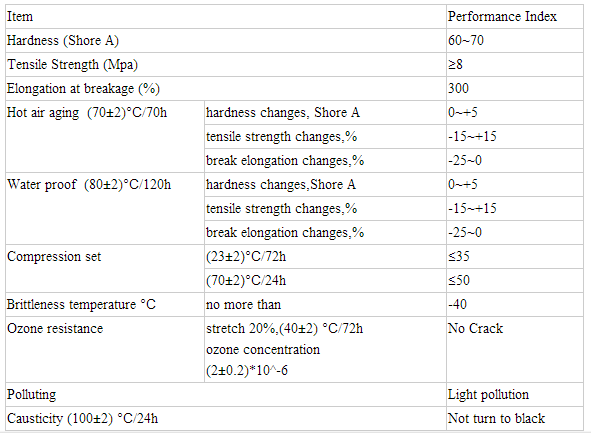

3. Main Specification of Custom Rubber Seal Strip for Door&Window Fireproof

4. Pictures of Custom Rubber Seal Strip for Door&Window Fireproof

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

6. Q: Your paymet terms?

A: We accept T/T, L/C, Paypal, Escrow, Western union, Money gram, D/P, D/A, Cash, and O/A.

- Q: How can I remove the rubber flavor on rubber products? It smells terrible

- Different types of rubber deodorant by different chemical AO and effect, which can effectively remove all kinds of rubber, including reclaimed rubber, flame retardant rubber smell in the processing and use of rubber products, improve the level of environmental protection, applicable to all kinds of rubber molding process. The utility model has the advantages of low use, high efficiency, safety and innocuity

- Q: How can I make rubber products brighter?

- Special release agent for rubber products, release agent.Mold release agent is an interface coating used on two surfaces that are easy to adhere to each other. It can make the surface of the material easy to break off, smooth and clean. Mold release agent is used in various molding processes, such as glass fiber reinforced plastics, metal die casting, polyurethane foam and elastomer, injection molding thermoplastic, vacuum foaming sheet and extrusion section. In molding, sometimes other plastics, such as plasticizers, leak to the interface, and then a surface remover is needed to remove it.

- Q: How can the frictional properties of rubber improve?

- Because of its high elasticity and low modulus, the friction and wear properties of rubber are greatly affected by their physical and mechanical properties. The hardness of rubber is smaller, contacting with a rigid object, the real contact area is large, and the real size of the contact area is an important factor, so the friction rubber hardness, have more effect on the friction performance.

- Q: How can rubber and mould not be bonded when producing rubber products?

- Mold release can not be solved, we can only start with the mold structure. Because the main reason for adhesion is the complex structure of the product, resulting in strong vacuum adsorption between the mold and the mold. In view of this, we can do a few more exhaust at the appropriate location of the mold. If allowed, you can also modify the product structure, of course, this is unlikely. But really can not do it, this is the best solution.

- Q: What's rubber skin?

- Rubber (Rubber): highly elastic polymeric material with reversible deformation. It is elastic at room temperature and can produce great deformation under very little external force. It can be restored to original state after removing external force. Rubber is completely amorphous polymer, its glass transition temperature (T, g) is low, the molecular weight is often large, more than hundreds of thousands.

- Q: What material is the rubber used in the tires?

- The main material of automobile tire is the most widely used rubber, natural rubber, polybutadiene rubber, styrene butadiene rubber, rubber and other Ding Ji. Early automobile tires are outside the tire structure, wherein the inner tube is made of rubber, rubber and tire cord fabric made by multilayer. Nowadays tubeless tires are mostly radial tyres. Radial tire early steel strengthened, with the development of chemical technology, replaced by synthetic fiber steel radial gradually by Kevlar and other lighter weight, higher strength.

- Q: How can there be a crack in the rubber ring?

- Problems in production:1) formulation design, oil or resin less material or caused by excessive or high temperature, poor liquidity and other reasons!2) when manufacturing, the product appears the hole which the exhaust is not good3) the raw material is too thick during production, and cracks are also caused.

- Q: What is rubber leather?

- High elasticity polymer. The word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process (see photo). In 1770, British chemist J. Priestley discovered that rubber could be used to erase pencil writing. The material used at that time was called rubber, which has been used so far. The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. Rubber is the basic raw material of rubber industry. It is widely used in making tyres, rubber hoses, tapes, cables and other kinds of rubber products.

- Q: What about the smell of smoked rubber products?

- The corresponding type of rubber deodorant is one of good methods for removing it, or to reduce the degradation of various rubber acids produced in the processing or in the process of the use of alkoxy compounds, aldehydes, vinyl compounds, peroxide and sulfide odor of chemical additives, the smell if inhaled for a long time will stimulate the senses, give people uncomfortable feeling even harmful to the body, have two times of pollution to the environment, the chemical composition of different varieties of rubber and the resulting odor molecules are different,

- Q: What are the bridge rubber air bags used for?

- Open the valve, inflated to the specified pressure, you can close the valve, must not exceed the pressure.

Send your message to us

Custom Rubber Seal Strip for Door&Window Fireproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords