Flat Rubber Sealing Strips Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Flat Rubber Sealing Strips Made in China:

1. Brief Description of Flat Rubber Sealing Strips Made in China

Building door & windows; curtain walls, Automobiles, trucks, boat, railway, plane, cabinet, bridge, equipment, industrial and agriculture machines etc.

2. Main Features of Flat Rubber Sealing Strips Made in China

1. Very soft and light weight, With smooth surface

2. Ozone and chemical resistance.

3. Good elasticity and flexibility.

4. Excellent weather resistant and water resistant

5. High and low temperature resistance

6. No penetrating smell.

7. Ensure long life to use under stable temperature.

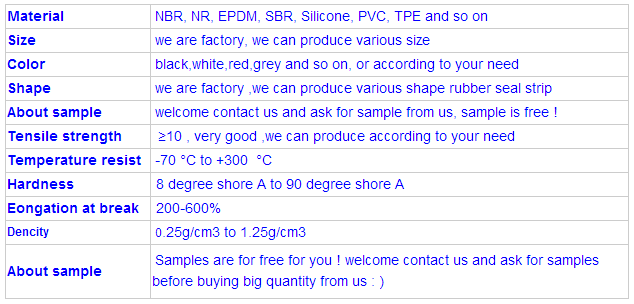

3. Main Specification of Flat Rubber Sealing Strips Made in China

4. Pictures of Flat Rubber Sealing Strips Made in China

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

- Q: Which is better waterproof performance, neoprene or silica gel?

- High temperature silicone rubber is mainly used for making all kinds of silicone rubber products, while room temperature silicone rubber is mainly used as adhesives, potting materials or dies. The maximum amount of heat curing type, heat curing type and methyl silicone rubber (MQ), methyl vinyl silicone rubber (VMQ, dosage and product grades at most), methyl vinyl silicone rubber (PVMQ low temperature resistance and radiation resistance), there are other eyes of silicone rubber, fluorine rubber and so on.

- Q: Excuse me, is PU one kind of silicone? Or what is the connection between the two?

- First of all, PU does not belong to silica gel, and PU refers to polyurethane. It is a kind of macromolecule material which is made up of organic diisocyanate or polyisocyanate and two hydroxyl or polyhydroxy compound. And silica gel is a common organic silica gel. The basic structure of organic silica gel is made up of silicon oxygen link, and the side chain is connected with other organic groups through silicon atom. So, these are two very different materials that make up the system. But because of the wide application of the two, they intersect in some application fields.

- Q: How are rubber wires processed?

- Extrusion processExtrusion process is through extrusion machine, barrel, cylinder wall and screw member role, so that the plastic to achieve extrusion and preliminary shape purposes, extrusion process, also known as extrusion process.Extrusion process is the main equipment extruder.Extrusion characteristics of several rubber: natural rubber extrusion speed, shrinkage of semi-finished products is small. The body temperature 50-60, head of 70-80 C, 80-90 type C; styrene butadiene rubber extrusion speed, compression deformation, surface roughness, body temperature 50-70, the temperature of 70-80 DEG C, die temperature is 100-105 DEG C; chloroprene rubber extrusion without sufficient thermal refining, body temperature of 50 DEG C, nose, mouth and 70 DEG C; ethylene propylene rubber extrusion speed, small shrinkage, body temperature 60-70, the temperature of 80-130 DEG C, C type 90-140. Acrylonitrile butadiene rubber extrusion performance is poor, extrusion should be fully hot refining. The body temperature is 50-60 degrees, and the nose temperature is 70-80 degrees centigrade.

- Q: Silicone is silicone rubber? Extracted from there?

- Inorganic silica gel is a kind of highly active adsorbent material, which is usually reacted with sodium silicate and sulfuric acid, followed by a series of post treatment processes such as aging and acid foaming.

- Q: Comparison of physical properties of HNBR rubber material with other rubber materials

- HNBR has a high temperature resistance of 130~180 degrees, cold resistance of -55 ~ -38 degrees, and good mechanical properties, compared with other polymers, can meet the requirements of the automotive industry. HNBR with ZnO/ methacrylate (MAA) can be used to make V-belt, triangular V-belt, multi base rubber, vibration isolator and so on. It can also prepare sealing ring, sealing element, heat resisting tube and so on. In oil drilling, rubber products are required to withstand high temperature, high pressure, acid, amines, H2S, CO2, CH4 and other tests of steam. The products prepared by HNBR can be acid resistant, oil resistant and solvent resistant. With the ZnO/MAA HNBR reinforcement can be used for the production of drilling mud pump piston and protection box. In addition, the beating method HNBR can be used as a sealing washer washer made of paper oil industry and automobile industry. HNBR heat and radiation resistance properties than silicon rubber, fluorine rubber, poly four vinyl chloride is better, suitable for all kinds of rubber seals for power station, is also used as a hydraulic pipe, hydraulic seals, power station for cable sheath, can also be used for printing and fabric roller, weapons components and aerospace seals, cover, fuel capsule; HNBR latex can be used as a surface coating (painting), textile, paper, leather, metal, ceramic fiber, non-woven adhesive, and foam rubber, latex impregnated products etc.. In addition, with ZnO/MAA, peroxide and high wear furnace HNBR, its comprehensive performance is better than ordinary HNBR.

- Q: How can there be a crack in the rubber ring?

- Problems in production:1) formulation design, oil or resin less material or caused by excessive or high temperature, poor liquidity and other reasons!2) when manufacturing, the product appears the hole which the exhaust is not good3) the raw material is too thick during production, and cracks are also caused.

- Q: The action of various ingredients in rubber formula

- Cost system: filler, compatibilizer

- Q: How to distinguish between silicone hose and rubber tube by appearance?

- Silicone hose is relatively soft, flexible, and looks better than other rubber tube gloss, color is mostly red, blue, translucent and other colors. Others, such as three yuan ethylene propylene and nitrile rubber hose, are basically black.

- Q: Is carbon black and conductive carbon black used in rubber?

- Carbon black is divided into two major categories according to its use and usage:1. Rubber carbon black2, non rubber carbon black (or special carbon black, dedicated carbon black), including pigment carbon black, conductive carbon black, carbon black used for plastics, and a variety of special carbon black and so onMay refer to: Li Bingyan edited the "carbon black production and Application Manual."

- Q: What are the hazards of waste rubber and how can they be used for regeneration?

- The disposal of waste rubber is one of the serious problems facing people today. In order to meet the requirements of materials to improve the performance of rubber, towards high strength, wear resistance, stability and aging resistance of the direction of development, but also caused a long period of rubber not biodegradable waste after a large number of waste rubber, causing than plastic pollution (white pollution) more difficult to deal with the black pollution. On the other hand, precious rubber resources are wasted.

Send your message to us

Flat Rubber Sealing Strips Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords