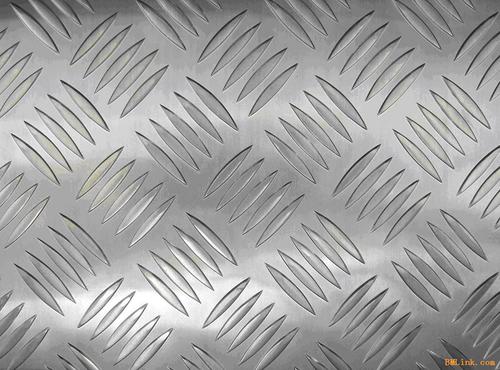

Expanded Aluminum Sheets - Small Five Bar Aluminum Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information:

1) Alloy: 1050. 1200, 1100,, 3003, 5052, 5754

2) Temper: H111, H112, O, H14, H24, H32

3) Thickness: 0.8mm to 10mm

4) Width: 100mm to 2300mm, Length: up to 11 Meter,

5) Patterns:Two bar,three bar, Five bar and diamond plate

6) Use: Refrigeration floor, Truck floor, flooring, stairs, indoor and outdoor decoration

Business Items:

1. Payment: T/T or LC at sight

2. Delivery time: 25 Days

3. Packing: 1. Standard seaworthy export packing, wooden pallets with plastic protection for sheets;

2. For the coil, the packing is eye to sky or eye to wall based on the client requirement;

3. 16-18 MT can be loaded into 20FCL.

4. Quality: Mill Finish, Totally free from defects like White Rust, Roll Marks, Edge damage , Camber,

Dents,Holes,Break Lines, Scratch

- Q: What are the different types of surface treatments for aluminum sheets in the marine industry?

- In the marine industry, aluminum sheets are widely used due to their lightweight, corrosion-resistant properties. To enhance the durability and performance of aluminum sheets in marine environments, various surface treatments are employed. These treatments provide an additional layer of protection against corrosion, oxidation, and other forms of wear and tear. Some of the different types of surface treatments for aluminum sheets in the marine industry include: 1. Anodizing: Anodizing is a common surface treatment for aluminum sheets. It involves creating an oxide layer on the surface of the aluminum through an electrochemical process. This oxide layer adds strength, improves corrosion resistance, and can also be dyed to provide aesthetic appeal. 2. Powder coating: Powder coating is a popular method to enhance the appearance and durability of aluminum sheets. It involves applying a dry powder to the surface of the aluminum and then heating it to create a protective coating. Powder coating provides excellent resistance to corrosion, UV rays, and scratches. 3. Chromate conversion coating: Chromate conversion coating, also known as chemical film coating or chromating, involves immersing the aluminum sheets in a solution containing chromate compounds. This process forms a thin layer of chromate conversion coating on the surface, which enhances corrosion resistance and provides a good base for subsequent painting or bonding. 4. Paint coating: Applying a paint coating to aluminum sheets is another surface treatment method in the marine industry. Paint coatings not only enhance the appearance but also provide a protective layer against corrosion, saltwater, and other harsh environmental conditions. Epoxy or polyurethane-based paints are commonly used for marine applications. 5. Mechanical treatments: Mechanical treatments such as brushing, grinding, or polishing can be performed on aluminum sheets to improve their surface finish. These treatments remove impurities, smoothing out any imperfections and enhancing the overall appearance of the aluminum surface. Each of these surface treatments has its own advantages and is chosen based on the specific requirements of the marine application. By selecting the appropriate surface treatment, manufacturers can ensure that aluminum sheets meet the necessary performance and durability standards in the demanding marine industry.

- Q: What are the different methods of finishing aluminum sheet edges?

- There are several methods that can be used to finish aluminum sheet edges, depending on the desired outcome and application. One common method is deburring, which involves removing any sharp or rough edges from the aluminum sheet. This can be done using various tools such as files, sandpaper, or specialized deburring machines. Deburring not only improves the appearance of the edges but also helps to prevent any potential injuries or accidents caused by sharp edges. Another method is chamfering, which involves creating a beveled edge on the aluminum sheet. This can be achieved using chamfering tools or by carefully filing or sanding the edges at a specific angle. Chamfering is often done to enhance the aesthetics of the aluminum sheet and to make it easier to handle and assemble. Additionally, edge rounding is a technique that involves smoothing the edges of the aluminum sheet to create a rounded or curved profile. This can be done using tools such as sanders, grinders, or specialized edge rounding machines. Edge rounding not only improves the visual appeal of the aluminum sheet but also helps to reduce the risk of injury from sharp edges. Furthermore, anodizing is a popular finishing method for aluminum sheet edges. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. This not only enhances the corrosion resistance of the aluminum but also provides a range of color options for the edges, allowing for customization and improved aesthetics. Lastly, powder coating is another method that can be used to finish aluminum sheet edges. Powder coating involves applying a dry powder onto the surface of the aluminum and then heating it to create a durable and decorative finish. This method offers a wide variety of colors, textures, and finishes, allowing for customization and enhanced visual appeal. Overall, the choice of finishing method for aluminum sheet edges will depend on factors such as the desired appearance, functionality, and application requirements. It is important to consider these factors and consult with experts to determine the most suitable method for a specific project.

- Q: I want to make a part using molten aluminum with a hole through the middle and would like to use a steel rod to do this. Would the bar stick to the aluminum when it cools and not be able to be removed? If so is there so type of coating I can use so it can be removed?

- Aluminium and iron are pretty incompatible materials, they don't form an alloy I don't think, so it is unlikely they would stick. Also, both metals will get an oxide layer on the surface which should keep them separate. Try it! If the finished part does stick, try heating the aluminium then dip the steel rod in some ice water.

- Q: If Aluminum can, in fact, not be sterilized I would love to know why.

- Sterilization refers to the ability to clean a surface of bacterium. Simply pouring rubbing alcohol on something sterilizes it. Aluminum can be sterilized just as good as any other metal. If it couldn't, would we ship our favorite drinks in cans of it?

- Q: What safety measures should be considered when handling large quantities of aluminum sheets?

- <p>When working with large amounts of aluminum sheets, it's important to take several precautions. Always wear protective gloves and eyewear to prevent cuts and eye injuries. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Use proper lifting techniques to avoid back injuries, and never exceed the weight limits of any equipment. Store aluminum sheets in a dry, cool place to prevent corrosion. Be cautious of static electricity buildup, which can be a fire hazard, especially in dry conditions. Finally, be aware of the risk of aluminum dust igniting, so avoid open flames and sparks near stored or processed aluminum sheets.</p>

- Q: Which kind of glue can bond hard shell plastic and iron sheet or aluminum sheet?

- you can use 520 or AB glue, and I think 520 is better.

- Q: What are the maximum dimensions of aluminum sheets?

- The maximum dimensions of aluminum sheets can vary depending on the manufacturing capabilities of different suppliers. However, in general, aluminum sheets are available in a wide range of sizes to meet various application requirements. Commonly, the maximum width of aluminum sheets can be up to 72 inches (6 feet), while the maximum length can reach around 240 inches (20 feet). These dimensions can provide ample material for a wide range of projects, including construction, manufacturing, and industrial applications. It is important to note that specific suppliers may have their own limitations, so it is advisable to consult with them directly to determine the maximum dimensions available for aluminum sheets.

- Q: What are the different methods of surface preparation for adhesive bonding of aluminum sheet?

- There are several different methods of surface preparation for adhesive bonding of aluminum sheet. These methods are used to ensure a strong and durable bond between the adhesive and the aluminum surface. One common method is mechanical abrasion, which involves roughening the surface of the aluminum sheet using abrasive materials such as sandpaper or wire brushes. This creates a textured surface that improves the adhesion of the adhesive. Another method is chemical etching, which involves treating the aluminum surface with a chemical solution to remove any oxide layer and create a clean and reactive surface. This can be done using acids or alkalis, depending on the specific requirements of the adhesive. Some adhesives require a clean surface free from any contaminants, so a method called solvent cleaning can be used. This involves using solvents such as acetone or isopropyl alcohol to remove any grease, oil, or dirt from the surface of the aluminum sheet. In addition to these methods, there are also specialized techniques such as anodizing and chromate conversion coating. Anodizing involves creating a thick oxide layer on the surface of the aluminum through an electrolytic process, which improves the bonding properties. Chromate conversion coating, on the other hand, involves treating the aluminum surface with a chemical solution containing chromates, which creates a protective layer and enhances adhesion. Overall, the choice of surface preparation method depends on the specific requirements of the adhesive and the desired bond strength. It is important to carefully select and follow the appropriate method to ensure a successful adhesive bonding of aluminum sheet.

- Q: This question asks for a list of various types of fasteners that can be used to secure aluminum windows to their frames.

- <p>There are several types of fasteners used for attaching aluminum windows to frames, including: 1. Screws: Commonly used for their secure hold and ease of installation. 2. Nails: Quick to use but may not provide the same level of security as screws. 3. Adhesives: Can be used for a more permanent bond, especially in certain applications. 4. Clips and brackets: Used for a more visible, decorative attachment. 5. Rivets: Provide a strong, permanent connection but are not easily removable. 6. Dowels and pins: Used for a more traditional or decorative join. 7. Structural glazing systems: Employ silicone or other sealants to bond the window to the frame. Each type of fastener has its own advantages and is chosen based on the specific requirements of the project, such as load-bearing needs, aesthetic considerations, and the desired level of permanence.</p>

- Q: What are the different manufacturing methods for aluminum sheets?

- There are several different manufacturing methods for aluminum sheets, each with its own unique characteristics and applications. 1. Rolling: The most common method of manufacturing aluminum sheets is through rolling. In this process, large slabs of aluminum are passed through a series of rollers, which reduce the thickness of the slab and increase its length. This method can produce sheets with consistent thickness and excellent surface finish. 2. Extrusion: Extrusion is another method used to manufacture aluminum sheets. In this process, a heated billet of aluminum is forced through a die, resulting in a continuous length of sheet. Extrusion allows for complex shapes and profiles to be created, making it suitable for applications such as building construction and automotive components. 3. Casting: Casting involves pouring molten aluminum into a mold and allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or sheets with specific alloy compositions. Casting can offer unique properties and is commonly used in industries such as aerospace and defense. 4. Cladding: Cladding is a process where a thin layer of aluminum is bonded to another material, such as steel or composite materials. This method combines the desirable properties of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets are commonly used in construction, transportation, and electrical industries. 5. Powder metallurgy: Powder metallurgy involves the formation of aluminum sheets from powdered aluminum particles. The powder is compacted into a desired shape and then sintered at high temperatures to fuse the particles together. This method is used for producing complex shapes and can provide improved mechanical properties. Each manufacturing method for aluminum sheets has its own advantages and disadvantages, depending on the desired properties, application, and cost considerations. Therefore, it is important to carefully select the most appropriate method based on the specific requirements of the project.

Send your message to us

Expanded Aluminum Sheets - Small Five Bar Aluminum Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords