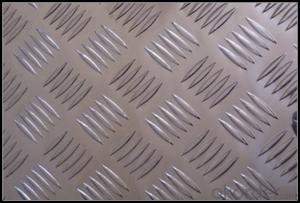

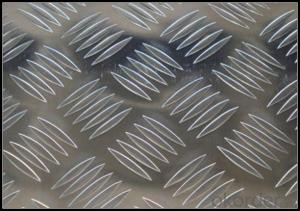

040 Aluminum Coil - Aluminium Checkered Sheet with Five Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Specifications of Aluminum Checkered Sheet

| MAIN SPECIFICATION OF ALUMINUM CHECKERED SHEET | |

| Alloy | AA1XXX (AA1050, AA1060, AA1070, AA1100 etc.) |

| AA3XXX (AA3003, AA3004, AA3005, AA3105 etc.) | |

| AA5XXX(AA5052) | |

| Temper | H14,H18,H24, H26, H32 |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

| Special specification is available on customer's requirement | |

2. Usage/Applications of Aluminum Checkered Sheet

The embossed aluminum sheet are widely used for decorative purposes in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packing & Delivery of Aluminum Checkered Sheet

Packaging: Seaworth package

Shipment: The goods will be delivered in not more than 40 days after getting the buyer's payment.

- Q: Can aluminum material be utilized as a baking surface for bread?

- <p>Aluminum coils are not typically used for baking bread. While aluminum is a good conductor of heat and is used in baking sheets and muffin tins, it's usually in a flat, solid form. Aluminum coils, often used for industrial purposes like heat exchangers, are not designed for direct food contact. For baking bread, it's best to use materials specifically designed for baking, such as silicone mats, parchment paper, or non-stick baking sheets. These materials are safe for food contact and can withstand the high temperatures required for baking bread.</p>

- Q: Can aluminum coils be used in low-friction applications?

- Low-friction applications can indeed make use of aluminum coils. Aluminum, being a lightweight and corrosion-resistant material, exhibits excellent thermal conductivity. These characteristics render it suitable for a variety of applications that prioritize low-friction. The automotive, aerospace, and HVAC industries often employ aluminum coils in heat exchangers, evaporators, condensers, and cooling coils. These coils are specifically designed to efficiently transfer heat while minimizing friction and energy loss. Furthermore, aluminum coils find utility in electrical motors, generators, and transformers, where smooth operation and reduced energy consumption are vital. Additionally, the lightweight nature of aluminum contributes to overall system weight reduction, thereby increasing efficiency. Moreover, various types of machinery and equipment that necessitate low friction, such as conveyor systems, sliding mechanisms, and bearings, can benefit from the utilization of aluminum coils. Aluminum's low coefficient of friction enables smooth and efficient movement, minimizing wear and tear on components. In conclusion, aluminum coils offer versatility in low-friction applications due to their lightweight, corrosion-resistant, and thermally conductive properties. Incorporating these coils can result in improved energy efficiency, reduced maintenance costs, and enhanced performance across a wide range of industries.

- Q: I have a muffin pan made of aluminum foil and I do not know if i can put it in the oven to cook some muffins. Many sights say it will melt but they say that about putting a sheet of foil at the bottom of the oven for a long time. I just want it to be in their for half an hour to make muffins.

- This Site Might Help You. RE: Can you put aluminum foil in the oven? I have a muffin pan made of aluminum foil and I do not know if i can put it in the oven to cook some muffins. Many sights say it will melt but they say that about putting a sheet of foil at the bottom of the oven for a long time. I just want it to be in their for half an hour to make muffins.

- Q: Can aluminum coils be used for decorative purposes?

- Aluminum coils offer a multitude of possibilities when it comes to decoration. This versatile material can be easily molded and adjusted, making it ideal for a wide range of decorative uses. In industries like architecture, interior design, and automotive design, aluminum coils are frequently employed to create decorative trims, accents, and borders. To further enhance their visual appeal and match the desired aesthetic, these coils can be painted or coated with different finishes. Moreover, thanks to their lightweight nature and durability, aluminum coils are a popular choice for outdoor decorative purposes, such as garden ornaments, sculptures, and signage. Ultimately, incorporating aluminum coils into various projects provides a cost-effective and visually pleasing solution for adding decorative elements.

- Q: Are aluminum coils suitable for architectural cladding?

- Yes, aluminum coils are suitable for architectural cladding. Aluminum is a lightweight and durable material that is often used in the construction industry for its versatility and aesthetic appeal. Aluminum coils can be easily formed into various shapes and sizes, making them ideal for architectural cladding applications. One of the key advantages of using aluminum coils for cladding is their resistance to corrosion. Aluminum naturally forms a protective oxide layer, which helps to prevent rusting and deterioration over time. This makes aluminum a long-lasting and low-maintenance option for architectural cladding. Additionally, aluminum coils offer a wide range of finishes and colors, allowing for greater design flexibility. They can be painted or coated to match any architectural style or design concept, making them a popular choice among architects and designers. Furthermore, aluminum is an environmentally friendly material. It is fully recyclable and has a much lower carbon footprint compared to other cladding materials like steel or concrete. This makes aluminum coils a sustainable choice for architectural projects. In summary, aluminum coils are indeed suitable for architectural cladding due to their durability, resistance to corrosion, design flexibility, and environmental benefits.

- Q: What does 1060 of the 1060 Aluminum rolls stand for?

- Can aluminium rolls be classified into nine categories? One series is the 1060 series, which represents the 1050106010701000 series aluminum plate, also known as pure aluminum. In all the series, the 1000 series belongs to a series with the largest amount of aluminum.

- Q: I have been reading up on thermite and the required ingredients. I have extremely fine aluminum powder from a small etch-a-sketch sitting on plastic wrap in my room. On the comments page of the site i got the thermite ingredients from, multiple people said that thermite could explose if you use too fine of a powder. I have also read that powdered aluminum can become very explosive when it is exposed to air or if it becomes damp. Ive gotten particulary worried because the humidity right now is 93%. So, is powdered aluminum too dangerous to have in house and is too fine powdered aluminum explosive when in thermite?

- It is now not aluminum powder; it's ALUM powder, which is one more chemical. Nonetheless, it would not fairly tighten your vagina, despite what some commercials will say. I've not heard of beydary capsules, but I also doubt that they might do anything to fix the predicament either. If a real vaginal shrinking capsule was once on hand, it would be recognized and really trendy, similar to viagra is. Your best wager is to do kegel exercises to fortify and tone your vaginal muscular tissues. These, and nothing else, can help make your vagina tighter.

- Q: How are aluminum coils packaged for transportation?

- Aluminum coils are typically packaged for transportation in a way that ensures their safety and prevents damage. The packaging process involves several steps to ensure that the coils are well-protected during handling, storage, and shipping. Firstly, the aluminum coils are usually wrapped in a protective material such as plastic or paper to safeguard them from dust, moisture, and other external factors. This wrapping helps to maintain the quality and integrity of the coils throughout the transportation process. After wrapping, the coils are then placed onto a pallet or wooden skid. This allows for easy handling with forklifts or other machinery during loading and unloading. The coils are securely strapped to the pallet to prevent any movement or shifting during transportation, minimizing the risk of damage. To provide additional protection, the coils may be placed inside a wooden or metal crate. This crate acts as a further barrier against potential impacts or rough handling that may occur during transit. The crates are carefully designed to fit the size and shape of the aluminum coils, ensuring a snug fit and preventing any unnecessary movement. Furthermore, depending on the specific requirements and distance of transportation, the coils may also be packed inside a shipping container. This offers an additional layer of protection against external elements and provides stability during long-distance transportation. Overall, the packaging process for aluminum coils prioritizes their safety and protection during transportation. The use of protective wrapping, pallets, crates, and shipping containers ensures that the coils arrive at their destination in optimal condition, ready for further processing or usage.

- Q: What are the storage life and shelf life of aluminum coils?

- The storage life and shelf life of aluminum coils can vary depending on various factors such as the storage conditions and the specific type of aluminum alloy used. Generally, aluminum coils have a relatively long storage life and shelf life. In terms of storage life, aluminum coils can be stored for an extended period of time without significant degradation in their quality or performance. However, it is important to store them in a dry and well-ventilated area to prevent corrosion. Moisture can cause oxidation and corrosion, which can affect the integrity and durability of the aluminum coils. As for the shelf life, aluminum coils can remain in good condition and retain their functional properties for an extended period of time when stored properly. The exact shelf life will depend on the specific application and the intended use of the aluminum coils. To ensure the longevity of aluminum coils, it is recommended to follow the manufacturer's guidelines for storage and handling. Additionally, regular inspections and maintenance can help identify any signs of corrosion or damage and take appropriate measures to prevent further deterioration.

- Q: What is the typical conductivity of aluminum coils?

- The typical conductivity of aluminum coils is high, ranging from approximately 35 to 40 million Siemens per meter (MS/m).

Send your message to us

040 Aluminum Coil - Aluminium Checkered Sheet with Five Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords