Geotextil Negro Filament Geotextile, Non Woven Spunbond Needle Punch Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

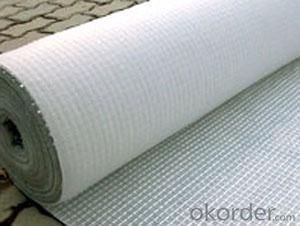

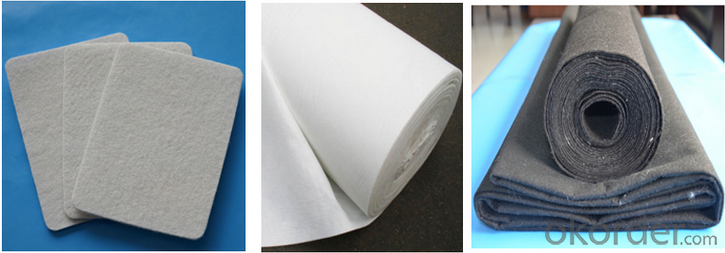

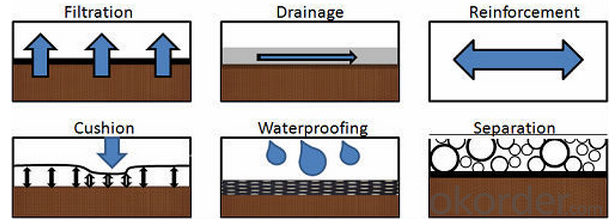

Filament Geotextiles are permeable nonwoven fabrics used to separate,filter,reinforce, protect or drainage.Geotextiles allow filtration or separation of granular layers in roads and rail applications,used to protect membranes in landfill applications,used in coastal defence applications and used in landscaping to protect surfaces and structures from weeds and root growth.

Filament Geotextiles are available as woven and non-woven .As liner protection, against physical damage, the non wovens are normally the answer.They are made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commonly used to separate layers like clay and drainage and to protect liner from damage.

Product Details

Features:

Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction

Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

Manufactured using a randomly orientated web to provide completely isotropic properties,ensuring that high strength is not limited to a single direction.

Excellent uniformity with high permeability and low pore size for soil filtration.

Supplied to a maximum width of 8.0 meters,ensuring minimum waste over large construction areas.

100% polypropylene or polyester staple fibers ,needle punched and random network formation.

UV and rot resistant and biological degradation resistant.

Majority Process:

Specific Data:

cItem | Area weight | Tensile Strength | Elongation | shrinkage | Roll Size | ||

MD | CMD | MD | CMD | ||||

Unit | G/M2 | N/125px | % | % | m x m | ||

Specification | 120 | ≥350 | ≥260 | 23 | 28 | <2.0< span=""> | 1.02x1700 |

140 | ≥380 | ≥300 | 25 | 30 | <1.0< span=""> | 1.01x1500 | |

150 | ≥500 | ≥330 | 28 | 35 | <1.0< span=""> | 1.01x1500 | |

160 | ≥550 | ≥350 | 30 | 35 | <1.0< span=""> | 1.01x1400 | |

180 | ≥600 | ≥450 | 30 | 35 | <1.0< span=""> | 1.01x1200 | |

200 | ≥750 | ≥450 | 30 | 35 | <1.0< span=""> | 1.01x1100 | |

220 | ≥800 | ≥500 | 30 | 35 | <1.0< span=""> | 1.01x1000 | |

250 | ≥950 | ≥600 | 35 | 40 | <1.0< span=""> | 1.01x800 | |

FAQ:

1. How to order your geotextile?

a). Tensile strength in warp & weft direction

b). gram per meter

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

3. Delivery time

a) 19-25 days after received your deposit .

4. What is MOQ ?

a) 2000 m2 as MOQ , we can also produce sample for you .

- Q: Can geotextiles be used in geogrid reinforcement applications?

- Yes, geotextiles can be used in geogrid reinforcement applications. Geotextiles are often used in combination with geogrids to enhance their performance and provide additional benefits such as soil separation, filtration, and erosion control.

- Q: Can geotextiles be used in green space development projects?

- Yes, geotextiles can be used in green space development projects. Geotextiles can provide various benefits such as erosion control, soil stabilization, and weed suppression, which are essential in creating and maintaining green spaces. By preventing soil erosion and promoting healthy plant growth, geotextiles contribute to the overall success of green space development projects.

- Q: Are geotextiles suitable for use in geocell mattress systems?

- Yes, geotextiles are suitable for use in geocell mattress systems. Geotextiles have excellent filtration and separation properties, which help in preventing soil erosion and maintaining stability within the geocell system. They also provide reinforcement and allow for the proper drainage of water, making them an ideal choice for use in geocell mattress systems.

- Q: Application standard of filament geotextile

- National standard for filament geotextiles GB / T-1998 Geosynthetics Filament anti - sticking acupuncture non - woven geotextiles, the latest standard GB / T - 2008.

- Q: Polypropylene geotextile and polyester geotextile with the naked eye how to distinguish

- Polypropylene compared to white, polypropylene fiber than polyester fiber density point, anti-aging anti-aging of polypropylene, polyester aging,

- Q: Geotextile fng-pet-250-400

- Production standards geotextile, geomembrane, composite geomembrane.

- Q: How do geotextiles help in gas venting?

- Geotextiles help in gas venting by providing a permeable barrier that allows the passage of gases while preventing the migration of soil particles. This allows gases, such as methane, to escape from the ground, reducing the risk of buildup and potential hazards.

- Q: Can geotextiles be used in the protection of underground cables and pipes?

- Yes, geotextiles can be used in the protection of underground cables and pipes. Geotextiles act as a barrier between the cables/pipes and surrounding soil, preventing potential damage caused by abrasion, puncture, or chemical reactions. They help distribute loads and provide stability, improving the overall performance and lifespan of underground infrastructure.

- Q: How do geotextiles help with reinforcement of geogrid reinforced soil slopes?

- Geotextiles help with the reinforcement of geogrid reinforced soil slopes by providing additional strength and stability to the system. They act as a separator between the soil and the geogrid, preventing soil particles from infiltrating the geogrid and reducing its effectiveness. The geotextiles also distribute the load evenly across the geogrid, improving its load-bearing capacity and reducing the potential for localized failures. Additionally, geotextiles can enhance the overall drainage and filtration properties of the slope, minimizing the risk of water accumulation and soil erosion.

- Q: How are geotextiles secured in place?

- Geotextiles are typically secured in place using various methods such as anchoring pins, stakes, or other mechanical devices that are driven into the ground. Additionally, they can also be secured using soil cover, rocks, or other heavy materials to prevent them from shifting or moving.

Send your message to us

Geotextil Negro Filament Geotextile, Non Woven Spunbond Needle Punch Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords