Fiberglass Mat Tissue Fiber Glass Wool Blanket Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Vacuum compressed packing in plastic PP/PE bag and plastic woven bag.

To increase loading quantity and reduce cost of transportation, all exported glass wool blanket would be packed

vacuum. However, due to excellent rebound property, when reach to destination our glass wool will rebound

almost to the original level within 1day after been unpacked.

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1) Heat insulation and heat preservation, sound adsorption and noise reduction

2) Low slag indusion content, thin and long inner fiber

3) Thermal stability, stable and high efficiency for a long time

4) High temperature heat-stability, durability, high temperature shrinkage resistance

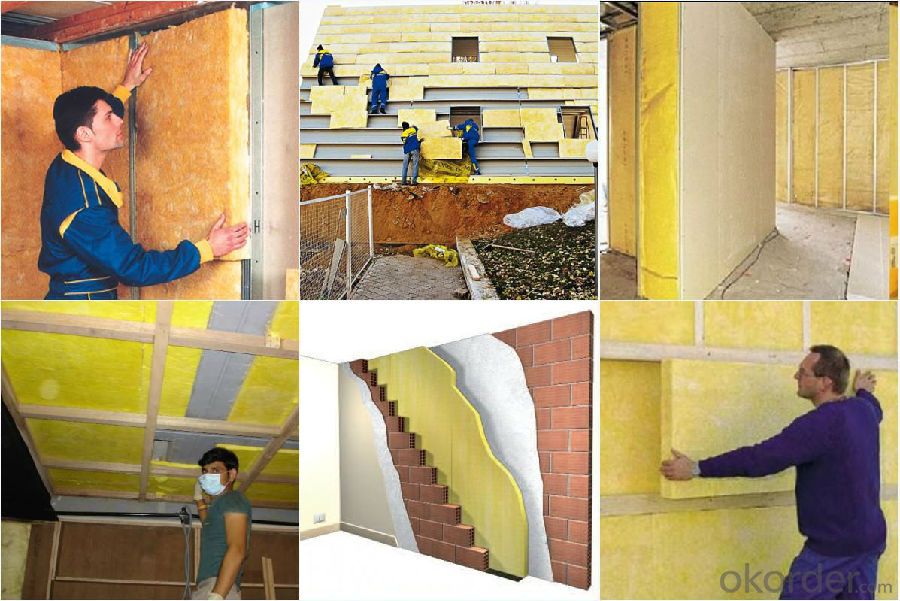

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How is fiberglass mat tissue used in the production of windshields?

- Fiberglass mat tissue is used in the production of windshields as a reinforcement material. It is sandwiched between layers of glass to increase the strength and durability of the windshield. This tissue provides added resistance to impacts, helps prevent cracks from spreading, and improves overall structural integrity.

- Q: How does the density of fiberglass mat tissue affect its performance?

- The density of fiberglass mat tissue directly affects its performance. Higher density fiberglass mat tissue tends to have better strength, durability, and heat resistance. It also offers improved sound insulation and fire retardant properties. On the other hand, lower density fiberglass mat tissue may provide better flexibility and conformability, making it suitable for certain applications. Overall, the density of fiberglass mat tissue plays a crucial role in determining its specific performance characteristics and suitability for different uses.

- Q: Can fiberglass mat tissue be used for insulating concrete forms (ICFs)?

- Yes, fiberglass mat tissue can be used for insulating concrete forms (ICFs). Fiberglass mat tissue acts as a reinforcement layer that can be applied directly to the surface of ICFs. It helps to provide additional strength and durability to the concrete, while also enhancing the insulation properties of the ICF system. The fiberglass mat tissue is typically embedded in a thin layer of adhesive or mortar, which helps to bond it to the ICF surface. This combination of fiberglass mat tissue and adhesive or mortar creates a strong, insulated barrier that helps to minimize heat loss and improve energy efficiency in a building. Additionally, fiberglass mat tissue is lightweight and easy to handle, making it a convenient choice for ICF installations.

- Q: How is fiberglass mat tissue used in the production of storage sheds?

- The production of storage sheds commonly utilizes fiberglass mat tissue due to its exceptional strength and durability. This material is typically employed as a reinforcement to enhance the structural integrity of the shed's walls, roof, and floor. During manufacturing, fiberglass mat tissue is frequently applied to both the exterior and interior surfaces of the shed. It is initially impregnated with a binding resin, usually polyester or epoxy. The resin-soaked fiberglass mat tissue is then layered onto the shed's panels or molds. Once in position, the resin is cured, either through heat application or a chemical reaction, which solidifies the material. This process creates a rigid, lightweight composite structure that is highly resistant to cracking, warping, and rotting, as well as being weather-resistant. The fiberglass mat tissue acts as a reinforcing layer, providing additional strength and stability to the shed. It helps evenly distribute loads across the structure, making it more resistant to impacts and external forces. Additionally, it prevents the shedding of particles, enhancing the overall appearance and cleanliness of the shed. Moreover, fiberglass mat tissue offers excellent thermal insulation. This insulation helps regulate the shed's temperature, keeping it cool in the summer and warm in the colder months. It also reduces energy costs by minimizing heat transfer. In conclusion, the inclusion of fiberglass mat tissue significantly improves the durability, strength, and insulation capabilities of storage sheds. It ensures a long-lasting and reliable structure that can withstand various weather conditions while providing a comfortable and secure storage space.

- Q: Can fiberglass mat tissue be used for repairing fiberglass jet skis?

- Yes, fiberglass mat tissue can be used for repairing fiberglass jet skis. It is a common material used in fiberglass repairs, providing strength and reinforcement to the damaged area.

- Q: Is fiberglass mat tissue suitable for insulation in food processing facilities?

- No, fiberglass mat tissue is not suitable for insulation in food processing facilities.

- Q: Can fiberglass mat tissue be used for making swimming pool shells?

- Swimming pool shells can indeed be constructed using fiberglass mat tissue. This material, widely used in the construction and manufacturing industries, possesses remarkable qualities. By combining fine glass fibers with a resin binder, it becomes a lightweight and pliable substance. The utilization of fiberglass mat tissue in swimming pool shell fabrication yields numerous advantages. Primarily, its exceptional resistance to water enables it to excel in pool applications. It also withstands the effects of common pool chemicals like chlorine, ensuring the longevity of the shell. In addition, fiberglass mat tissue is highly adaptable and can be molded into various shapes and sizes. This permits the creation of bespoke swimming pool shells that cater to specific requirements and preferences. Its flexibility also enables it to endure ground movement and temperature changes, thereby guaranteeing the pool shell's structural integrity. Moreover, fiberglass mat tissue boasts a smooth surface finish, providing both visual and tactile appeal. It can be easily painted or coated with gel coats to enhance its appearance and safeguard it from harmful UV rays, preventing discoloration and deterioration over time. In conclusion, fiberglass mat tissue emerges as an exceptional option for constructing swimming pool shells due to its water and chemical resistance, flexibility, durability, and aesthetic appeal.

- Q: Can fiberglass mat tissue be used for making surfboards?

- Yes, fiberglass mat tissue can be used for making surfboards. It is a common material used in the construction of surfboards due to its strength, durability, and ability to provide the necessary stiffness and flexibility required for optimal performance in the water.

- Q: What are the different manufacturing processes for fiberglass mat tissue?

- There are several different manufacturing processes for fiberglass mat tissue, including wet-laid process, dry-laid process, and spunbonding process. The wet-laid process involves blending fiberglass fibers with a water-based binder, forming a mat, and then drying it. The dry-laid process, on the other hand, uses air to disperse the fibers onto a moving conveyor belt, which are then bonded together using heat and pressure. The spunbonding process involves extruding molten fiberglass polymer through fine nozzles, which solidifies into continuous filaments that are then collected onto a conveyor belt to form a mat.

- Q: Can fiberglass mat tissue be used for repairing fiberglass canoes?

- Indeed, fiberglass canoes can be repaired using fiberglass mat tissue. This lightweight material is typically employed to reinforce fiberglass structures, and it is frequently utilized in the realm of boat repairs due to its ability to enhance strength and durability in the mended region. The mat tissue is specifically crafted to be effortlessly molded and shaped, rendering it ideal for rectifying curved surfaces like canoes. Furthermore, fiberglass mat tissue harmonizes with commonly used polyester and epoxy resins in fiberglass repairs. Consequently, it is a fitting substance for the restoration of fiberglass canoes, effectively reinstating the structural integrity of the afflicted portions.

Send your message to us

Fiberglass Mat Tissue Fiber Glass Wool Blanket Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords