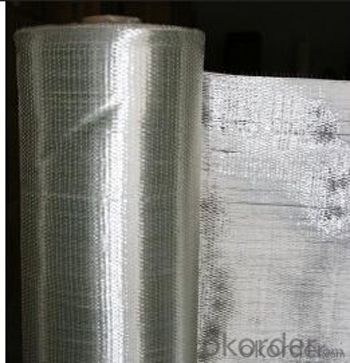

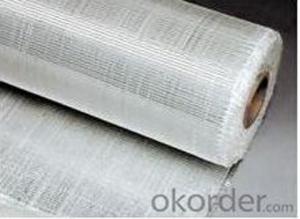

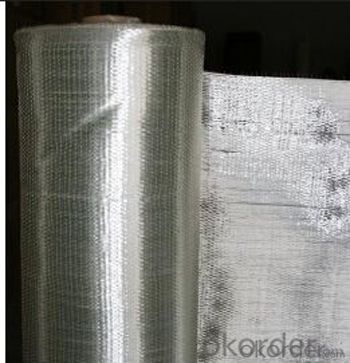

Fiberglass Mat Tissue Unidirectional Fabric 600gsm 1524mm Length

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Unidirectional Fabric with Density 600gsm Length 1524mm

Description

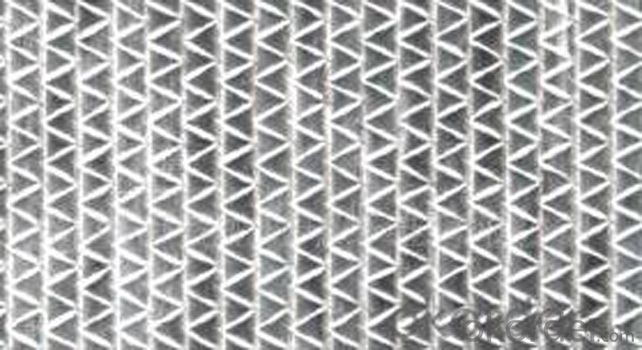

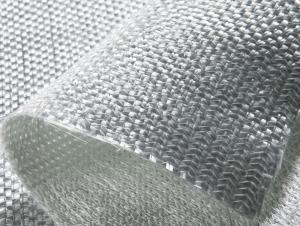

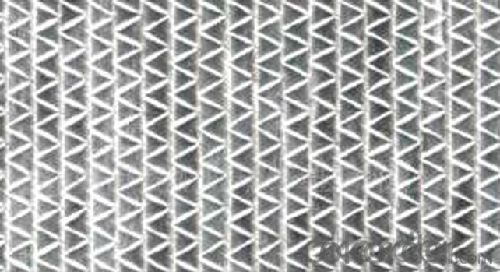

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.

Features

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Image:

Features

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Specifications

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control systempment;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before ship

d, Sample stock for one year for quality tracing and record.

- Q: How does fiberglass mat tissue perform in terms of UV resistance?

- Fiberglass mat tissue generally has good UV resistance. UV resistance refers to the ability of a material to withstand the harmful effects of ultraviolet radiation from the sun without degrading or deteriorating. Fiberglass mat tissue is usually manufactured using a combination of fiberglass and a binder material, which provides strength and integrity to the tissue. The fiberglass component in the mat tissue provides inherent UV resistance. Fiberglass is known for its durability and ability to resist degradation from UV exposure. It is a non-porous material that does not absorb UV radiation, making it less susceptible to damage caused by the sun's rays. Additionally, some manufacturers may apply a UV-resistant coating or treatment to the fiberglass mat tissue to enhance its UV resistance. This coating or treatment can further protect the tissue from the damaging effects of prolonged exposure to UV radiation. Overall, fiberglass mat tissue performs well in terms of UV resistance. It is a durable material that can withstand the harmful effects of UV radiation, making it suitable for applications where prolonged exposure to sunlight is expected. However, it is important to note that the specific UV resistance of fiberglass mat tissue may vary depending on the manufacturing process, quality of materials used, and any additional coatings or treatments applied.

- Q: Can fiberglass mat tissue be used for flooring insulation?

- Typically, fiberglass mat tissue is not employed for flooring insulation. It is a lightweight substance frequently utilized in the construction sector to reinforce plaster and concrete, and as insulation in walls and ceilings. However, for flooring insulation purposes, other materials like foam boards or batt insulation are generally favored. These materials offer superior thermal and sound insulation features that are specifically tailored for flooring applications. Moreover, they are simpler to install and better equipped to endure the pressures and demands of foot traffic on the flooring.

- Q: What are the different fabric finishes available for fiberglass mat tissue?

- There are several different fabric finishes available for fiberglass mat tissue, each offering unique properties and characteristics. Some of the most common fabric finishes include: 1. Polyester: Polyester fabric finishes are widely used in fiberglass mat tissue as they provide excellent strength and durability. This finish helps to improve the overall tear resistance and tensile strength of the fiberglass mat tissue. 2. Polypropylene: Polypropylene fabric finishes are known for their high resistance to chemicals and moisture. This finish helps to enhance the water resistance properties of the fiberglass mat tissue, making it suitable for applications where moisture or chemical exposure is a concern. 3. Acrylic: Acrylic fabric finishes provide good heat resistance and flame retardancy to the fiberglass mat tissue. This finish helps to improve the thermal stability and fire resistance of the material, making it suitable for applications where high temperatures or fire hazards are present. 4. Nylon: Nylon fabric finishes are known for their excellent abrasion resistance and toughness. This finish helps to enhance the durability and wear resistance of the fiberglass mat tissue, making it ideal for applications where frequent contact or friction may occur. 5. Polyethylene: Polyethylene fabric finishes offer excellent resistance to moisture and chemicals. This finish helps to improve the overall water repellency and chemical resistance of the fiberglass mat tissue, making it suitable for outdoor or corrosive environments. 6. Polyurethane: Polyurethane fabric finishes provide good flexibility and elasticity to the fiberglass mat tissue. This finish helps to enhance the material's ability to withstand bending and stretching without breaking or tearing. Overall, the choice of fabric finish for fiberglass mat tissue depends on the specific application requirements. It is important to consider factors such as strength, durability, water resistance, flame retardancy, abrasion resistance, and chemical resistance when selecting the appropriate fabric finish for a particular application.

- Q: Can fiberglass mat tissue be used for boat building?

- Certainly, fiberglass mat tissue is a viable option for boat construction. It is a versatile and lightweight material that is frequently utilized in the building of boats. Its composition consists of thin fiberglass strands woven together to form a mat-like structure. This material is renowned for its exceptional strength-to-weight ratio, making it an optimal selection for boat builders. The utilization of fiberglass mat tissue in boat construction primarily serves to fortify the structure and provide added durability. It can be applied to various parts of the boat, including the hull and deck, to enhance its resilience and safeguard it against impacts. Moreover, it can be employed to create a smooth and uniform surface, which is crucial for achieving a professional-grade finish. One of the notable advantages of employing fiberglass mat tissue in boat construction lies in its ease of application. It can be effortlessly tailored to the desired size and molded to fit the desired shape, allowing for flexibility and customization. Additionally, it can be easily layered with other materials, such as epoxy resin, to create a robust and dependable composite. Furthermore, fiberglass mat tissue exhibits exceptional resistance to water and corrosion, rendering it suitable for marine environments. It is also recognized for its superb thermal and electrical insulation properties, both of which are highly advantageous for boat builders. In summary, fiberglass mat tissue is indeed a suitable choice for boat construction. Its lightweight nature, impressive strength, and resistance to water and corrosion establish it as a dependable and popular option among boat builders.

- Q: How is fiberglass mat tissue used in the production of storage sheds?

- Fiberglass mat tissue is commonly used in the production of storage sheds due to its excellent strength and durability properties. It is typically employed as a reinforcement material to add structural integrity to the shed's walls, roof, and floor. During the manufacturing process, fiberglass mat tissue is often applied to the shed's exterior and interior surfaces. It is first impregnated with a resin, usually polyester or epoxy, which acts as a binder. The resin-soaked fiberglass mat tissue is then layered onto the shed's panels or molds. Once in place, the resin is cured, either through the application of heat or a chemical reaction, which hardens the material. This process creates a rigid, lightweight, and weather-resistant composite structure that is highly resistant to cracking, warping, or rotting. The fiberglass mat tissue serves as a reinforcing layer, providing added strength and stability to the shed. It helps distribute loads evenly across the structure, making it more resistant to impacts or external forces. Additionally, the fiberglass mat tissue helps prevent the shedding of particles, enhancing the overall appearance and cleanliness of the shed. Furthermore, fiberglass mat tissue offers excellent thermal insulation properties. This insulation helps regulate the temperature inside the shed, keeping it cooler during hot summer months and warmer during the colder seasons. It also aids in reducing energy costs by minimizing heat transfer. Overall, the use of fiberglass mat tissue in the production of storage sheds significantly enhances their durability, strength, and insulation capabilities. It ensures a long-lasting and reliable structure that can withstand various weather conditions while providing a comfortable and secure storage space.

- Q: What is the flexibility of fiberglass mat tissue at low temperatures?

- The flexibility of fiberglass mat tissue at low temperatures is generally maintained, as fiberglass has low thermal expansion and contraction properties, allowing it to retain its flexibility even in cold conditions.

- Q: Can fiberglass mat tissue be used for ceiling insulation?

- No, fiberglass mat tissue is not suitable for ceiling insulation. While fiberglass mat tissue is commonly used in various construction applications, such as reinforcing plaster or other building materials, it is not designed or recommended for insulation purposes. When it comes to ceiling insulation, there are specific materials that are more suitable and effective, such as fiberglass batts, cellulose, or foam insulation. These materials are specifically engineered to provide thermal resistance and reduce the transfer of heat between the interior and exterior of a building. Using fiberglass mat tissue as ceiling insulation would not only be ineffective in providing proper insulation, but it may also pose safety risks. Fiberglass mat tissue is typically thin and lacks the necessary thickness to effectively insulate ceilings. Additionally, fiberglass insulation materials are known to release airborne particles and fibers, which can be hazardous to health if inhaled. Therefore, it is important to use the appropriate insulation materials that are specifically designed for ceiling insulation to ensure energy efficiency, comfort, and safety in your home or building.

- Q: Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a versatile material that is commonly used in various insulation applications due to its excellent thermal insulation properties. It is lightweight, flexible, and provides effective insulation against heat transfer. When used in insulation jackets, fiberglass mat tissue can help to retain heat and prevent heat loss, making it an ideal choice for applications where thermal insulation is required. Additionally, fiberglass mat tissue is also fire-resistant, which further enhances its suitability for insulation jackets.

- Q: What is the thermal resistance of fiberglass mat tissue?

- The thermal resistance of fiberglass mat tissue typically ranges from 0.3 to 0.6 square meters Kelvin per watt (m²K/W), depending on the specific composition and thickness of the material.

- Q: What are the potential health hazards associated with working with fiberglass mat tissue?

- Potential health hazards associated with working with fiberglass mat tissue include skin irritation, respiratory issues such as coughing and wheezing, eye irritation, and allergic reactions. Long-term exposure to fiberglass fibers can also lead to a condition called fiberglass lung, which is characterized by chronic coughing, chest tightness, and difficulty breathing. It is important to use proper protective equipment, such as gloves, goggles, and a respirator, when working with fiberglass mat tissue to minimize these risks.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 600gsm 1524mm Length

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords