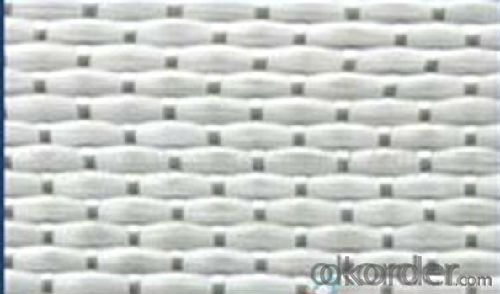

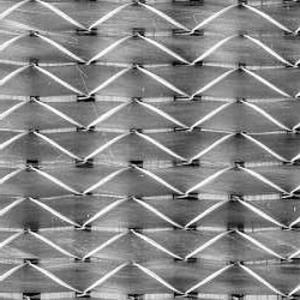

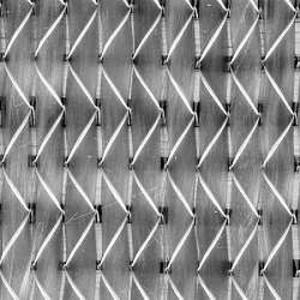

Fiberglass Mat Tissue - Multiaxial Fabric-UD 90 Degree-500g/m2

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Benefits :

• Good mouldability • Stable resin speed for vacuum infusion process • Good combination with resin and no white fiber (dry fiber) after curing

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

FAQ 1) which kind of glass fiber sample and materials can you provide? We can provide the glass fiber and glass fiber down stream products samples of E glass, C glass, ECR glass, High alkali glass. The products includes single end roving, assembled roving for different applications( Piping, SMC, panel, winding mill plate) , chop strand for BMC, engineering plastic (PA, PPA, PPT, POM, etc), chop strand mat (from 100gsm-900gsm) for automobile and water tank, etc, woven roving (270gsm-800gsm), surface tissue (25-50gsm), multi-axial fabric of different unit weight. 2) Can you provide glass fiber composite material? We can provide GFRP profile such as grating, T beam, U beam and other assembles pieces such as GFRP triangle frame, dust bin, fireplace, etc 3) How much sample can you provide and who will bear the

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: Is fiberglass mat tissue suitable for wind energy applications?

- Yes, fiberglass mat tissue is suitable for wind energy applications. It is commonly used as a reinforcement material in wind turbine blades due to its high strength-to-weight ratio, excellent fatigue resistance, and ability to withstand harsh environmental conditions. The fiberglass mat tissue enhances the structural integrity and durability of the blades, enabling them to efficiently capture wind energy and sustain long-term operation.

- Q: Can fiberglass mat tissue be used for acoustic insulation?

- Yes, fiberglass mat tissue can be used for acoustic insulation. Fiberglass mat tissue is a lightweight material that has excellent sound absorption properties. It can effectively absorb and dampen sound waves, reducing noise and improving the acoustic environment. Fiberglass mat tissue is commonly used in the construction industry for insulating walls, ceilings, and floors to reduce noise transmission. It is also used in automotive applications and other industries where sound insulation is required. Its high porosity and fibrous structure make it an ideal material for absorbing and attenuating sound waves, making it suitable for acoustic insulation.

- Q: How is fiberglass mat tissue used in the construction industry?

- Fiberglass mat tissue is widely used in the construction industry for various applications. This material is made up of thin strands of glass fibers that are bonded together with a resin. It offers several properties that make it suitable for construction purposes. One common use of fiberglass mat tissue is in the production of roofing materials. It is often used as a reinforcement layer in roofing shingles or sheets. The fiberglass mat tissue adds strength and durability to the roof, making it more resistant to weather elements such as wind, rain, and hail. Additionally, it helps to prevent cracking and splitting, prolonging the lifespan of the roofing material. Another application of fiberglass mat tissue in the construction industry is in the production of composite materials. It is commonly used as a reinforcement layer in composite panels and boards. The fiberglass mat tissue enhances the strength and stiffness of the composite material, making it suitable for various structural applications. It is also lightweight, which makes it an ideal choice for building materials that require both strength and reduced weight. Fiberglass mat tissue is also used in the construction of walls and ceilings. It can be applied as a layer between the gypsum board and the insulation material to provide additional strength and resistance to impacts. This helps to prevent cracks and damage to the walls or ceilings, enhancing the overall structural integrity of the building. Furthermore, fiberglass mat tissue finds application in the construction of pipes and tanks. It is used as a reinforcement layer in the manufacturing of fiberglass-reinforced plastic (FRP) pipes and tanks. The fiberglass mat tissue adds strength and rigidity to the FRP structure, making it suitable for various industrial applications, including chemical processing, wastewater treatment, and oil and gas industries. In conclusion, fiberglass mat tissue is widely used in the construction industry for its strength, durability, and lightweight properties. It is utilized in roofing materials, composite panels, walls, ceilings, pipes, and tanks, among other applications. Its versatility and performance make it a preferred choice among construction professionals for enhancing the structural integrity of various building components.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Yes, fiberglass mat tissue typically provides some level of UV resistance. The fiberglass mat tissue is made up of glass fibers that are embedded in a matrix of resin. These fibers and resin provide some degree of protection against UV radiation from the sun. However, it is important to note that the level of UV resistance may vary depending on the specific composition and manufacturing process of the fiberglass mat tissue. Additionally, prolonged exposure to UV radiation can still cause some degradation over time, so it is recommended to take appropriate measures such as using UV-resistant coatings or finishes to enhance the durability and lifespan of the fiberglass mat tissue in outdoor applications.

- Q: How does fiberglass mat tissue compare to polyurethane insulation?

- Fiberglass mat tissue and polyurethane insulation have different characteristics and purposes. Fiberglass mat tissue is commonly used as a reinforcing material in composite structures, providing strength and stability. On the other hand, polyurethane insulation is specifically designed to reduce heat transfer and improve energy efficiency in buildings. Therefore, while fiberglass mat tissue enhances structural integrity, polyurethane insulation primarily focuses on thermal insulation properties.

- Q: How is fiberglass mat tissue used in the production of water tanks?

- Fiberglass mat tissue, which is made from glass fibers and falls under the category of non-woven fabric, is widely utilized in the manufacturing of water tanks due to its exceptional strength, durability, and resistance to corrosion. Typically, water tanks are constructed using fiberglass reinforced plastic (FRP), a composite material comprising a polymer matrix with fiberglass reinforcement. In this process, the fiberglass mat tissue plays a vital role as the material for reinforcement. To begin, the fiberglass mat tissue is cut into the desired shape and size to fit the mold of the water tank. It is then applied in layers onto the mold, with the number of layers determined by the required strength and thickness of the tank. Once in place, a resin matrix is used to impregnate and bind the fibers of the fiberglass mat tissue together. The specific resin employed, whether polyester, vinyl ester, or epoxy, depends on the particular requirements of the water tank. Typically, the resin is applied by either spraying or using a roller, ensuring complete saturation of the fiberglass mat tissue. This process is often repeated multiple times to achieve the desired thickness and strength of the tank. After the resin has cured, the fiberglass mat tissue and resin composite become rigid, forming the structure of the water tank. The resulting FRP tank is lightweight yet remarkably strong and durable, making it an excellent choice for water storage and transportation. The use of fiberglass mat tissue in water tank production offers several advantages. Firstly, it enhances the structural integrity of the tank, enabling it to withstand external forces such as pressure and impact. Secondly, fiberglass exhibits a high resistance to corrosion, ensuring that the tank remains in optimal condition even when exposed to harsh environmental conditions or corrosive substances present in the water. In conclusion, fiberglass mat tissue is an essential element in the production of water tanks, providing strength, durability, and corrosion resistance. This makes it a reliable option for various industrial, commercial, and residential applications.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The surface finish of fiberglass mat tissue can significantly affect its adhesion to resin. The surface finish refers to the texture or smoothness of the fiberglass mat tissue. In general, a rougher surface finish tends to provide better adhesion to resin. This is because a rough surface provides more surface area for the resin to adhere to, allowing for a stronger bond. Rougher surface finishes can be achieved through various manufacturing techniques, such as using coarser fibers or adding texturizing agents during production. On the other hand, a smoother surface finish may result in weaker adhesion. A smooth surface does not provide as much surface area for the resin to bond with, leading to a weaker and less durable bond. Smoother surface finishes can be achieved by using finer fibers or through additional processing steps to smooth out the surface. It is important to consider the specific application and requirements when choosing the surface finish of fiberglass mat tissue. For applications that require high strength and durability, a rougher surface finish may be preferred to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a critical role in determining the adhesion to resin. It is essential to select the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: Can fiberglass mat tissue be used for wind turbine blades?

- Yes, fiberglass mat tissue can be used for wind turbine blades. It is commonly used as a reinforcement material in wind turbine blade manufacturing due to its high strength, lightweight nature, and excellent corrosion resistance.

- Q: What is the weight of fiberglass mat tissue per square meter?

- The weight of fiberglass mat tissue per square meter can vary depending on the specific product and manufacturer. However, on average, fiberglass mat tissue typically weighs around 100-300 grams per square meter.

- Q: What is the thermal stability of fiberglass mat tissue?

- The thermal stability of fiberglass mat tissue is quite high. It can withstand high temperatures without significant degradation or loss of its structural integrity.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD 90 Degree-500g/m2

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords