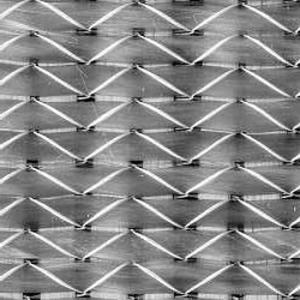

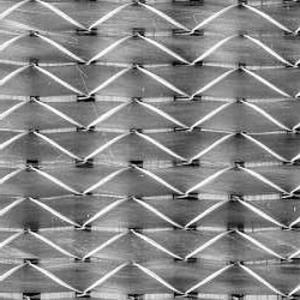

Fiberglass Mat Tissue - Multiaxial Fabric-UD (0° or 90°) 880/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Can fiberglass mat tissue be used as a reinforcement in concrete?

- Yes, fiberglass mat tissue can be used as a reinforcement in concrete. Fiberglass mat tissue is a thin, lightweight material made from woven fiberglass strands. It is commonly used in construction and industrial applications due to its high strength and durability. When used as reinforcement in concrete, fiberglass mat tissue can help to increase the tensile strength and crack resistance of the concrete. It is typically applied in the form of a mesh or fabric, which is embedded within the concrete during the pouring process. The fiberglass strands in the mat tissue provide additional strength and reinforcement to the concrete, helping to prevent cracking and improve overall structural integrity. This can be particularly beneficial in areas where the concrete is subject to high loads, such as in bridges, concrete slabs, or precast concrete elements. Furthermore, fiberglass mat tissue is corrosion-resistant, which makes it a suitable choice for applications where the concrete is exposed to moisture or chemicals. It does not rust or degrade over time, unlike traditional steel reinforcement, which can help to extend the lifespan of the concrete structure. Overall, fiberglass mat tissue is a viable and effective reinforcement option for concrete. It offers enhanced strength, crack resistance, and corrosion resistance, making it a popular choice in various construction projects.

- Q: Can fiberglass mat tissue be used for boat building?

- Yes, fiberglass mat tissue can be used for boat building. It is commonly used as a reinforcement material in boat construction due to its strength, durability, and ability to resist water damage.

- Q: How does the density of fiberglass mat tissue impact its performance?

- The density of fiberglass mat tissue significantly affects its performance. Fiberglass mat tissue is a nonwoven material composed of randomly dispersed glass fibers held together by a binder. The density of the tissue refers to the amount of fibers present in a given volume of the material. A higher density of fiberglass mat tissue generally results in improved mechanical properties and performance. The increased density means that there are more glass fibers per unit volume, leading to enhanced strength, stiffness, and durability. This makes the material more resistant to tearing, puncturing, and abrasion, which is particularly important in applications where the tissue is exposed to harsh conditions or heavy loads. Moreover, a higher-density fiberglass mat tissue offers better thermal insulation properties. The increased fiber content allows for better heat resistance, making it suitable for applications that require thermal protection, such as insulation boards or fireproofing materials. On the other hand, a lower density of fiberglass mat tissue may provide advantages in certain applications. Lower-density tissues are generally more flexible and have better conformability, allowing them to easily adapt to irregular surfaces or complex shapes. This makes them suitable for applications where flexibility or conformability is a primary requirement, such as in automotive or aerospace industries. Overall, the density of fiberglass mat tissue plays a crucial role in determining its performance characteristics. Whether a higher or lower density is preferred depends on the specific application requirements, considering factors such as strength, stiffness, durability, thermal insulation, flexibility, and conformability.

- Q: Does fiberglass mat tissue provide good fire protection?

- No, fiberglass mat tissue does not provide good fire protection.

- Q: Can fiberglass mat tissue be used for automotive parts?

- Automotive parts can indeed utilize fiberglass mat tissue. This adaptable material offers strength, rigidity, and durability. Within the automotive industry, it finds widespread use in a range of applications including reinforcing panels, bumpers, hoods, and body parts. Its lightweight composition makes it ideal for reducing vehicle weight and enhancing fuel efficiency. Moreover, it boasts resistance against corrosion, chemicals, and extreme temperatures, rendering it a dependable choice for automotive parts. Its flexibility further enables manufacturers to easily mold and shape it, facilitating the creation of intricate designs and desired aesthetics. Considering its strength, durability, lightweight nature, and versatility, fiberglass mat tissue stands as an exceptional option for automotive parts.

- Q: What is the moisture absorption rate of fiberglass mat tissue?

- The moisture absorption rate of fiberglass mat tissue can vary depending on various factors such as the specific type of fiberglass mat tissue and its manufacturing process. However, in general, fiberglass mat tissue is known to have a relatively low moisture absorption rate. This is due to the hydrophobic nature of fiberglass, which means it repels water and is not easily permeated by moisture. As a result, fiberglass mat tissue is often used in applications where moisture resistance is important, such as in roofing materials, insulation, and automotive parts. While the exact moisture absorption rate may not be readily available without specific product information, fiberglass mat tissue is generally considered to be a moisture-resistant material.

- Q: Can fiberglass mat tissue be used for making surfboards?

- Yes, fiberglass mat tissue can be used for making surfboards. Fiberglass mat tissue is a lightweight and strong material that is commonly used in the construction of surfboards. It is typically layered with epoxy resin to create a durable and rigid surface. The fiberglass mat tissue provides strength and flexibility to the surfboard, allowing it to withstand the pressures and forces experienced while riding waves. Additionally, the smooth and sleek surface of the fiberglass mat tissue helps to enhance the performance and speed of the surfboard. Overall, fiberglass mat tissue is a popular choice for surfboard construction due to its excellent strength-to-weight ratio and ability to create high-performance boards.

- Q: Can fiberglass mat tissue be used for repairing fiberglass fenders?

- Yes, fiberglass mat tissue can be used for repairing fiberglass fenders. It is commonly used in fiberglass repair work to reinforce and strengthen damaged areas.

- Q: Can fiberglass mat tissue be used for making lightweight stairs?

- Yes, fiberglass mat tissue can be used for making lightweight stairs. Fiberglass mat tissue is a lightweight and strong material that can be easily molded into various shapes, including stairs. It offers excellent strength-to-weight ratio, making it ideal for constructing lightweight structures such as stairs. Additionally, fiberglass is durable, corrosion-resistant, and non-conductive, making it a suitable choice for stairs that need to withstand heavy use and harsh environmental conditions.

- Q: What are the different color options available for fiberglass mat tissue?

- Various color options are offered for fiberglass mat tissue, catering to different preferences and applications. White, gray, black, and beige are among the commonly available colors. These color choices offer versatility in design and aesthetics, allowing users to select a color that enhances their individual project needs. Factors like UV resistance and desired visibility or camouflage levels can also influence the color selection. In conclusion, the availability of diverse color options for fiberglass mat tissue grants users the flexibility and customization opportunities necessary to achieve their desired results.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD (0° or 90°) 880/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords