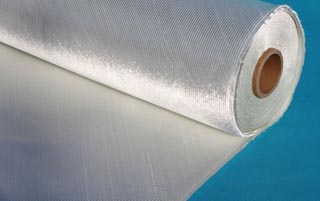

Fiberglass Multiaxial Fabric-UD 600gsm for wind power industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

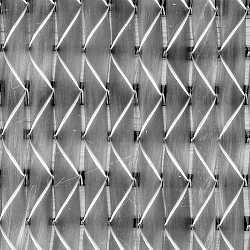

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Images:

- Q: How does the fiber distribution of fiberglass mat tissue affect its strength?

- The fiber distribution of fiberglass mat tissue plays a crucial role in determining its strength. A more uniform and evenly distributed fiber arrangement enhances the overall strength and structural integrity of the material. This is because the fibers can effectively distribute and share the applied load, preventing localized stress concentrations and potential weak points. In contrast, an uneven or random fiber distribution may lead to areas with fewer or misaligned fibers, reducing the material's overall strength and making it more prone to failure. Therefore, a well-controlled and uniform fiber distribution is essential for maximizing the strength and performance of fiberglass mat tissue.

- Q: Is fiberglass mat tissue suitable for insulation in cold storage facilities?

- Yes, fiberglass mat tissue is suitable for insulation in cold storage facilities. It offers excellent thermal insulation properties and is commonly used in such environments to maintain low temperatures and prevent heat transfer. Additionally, fiberglass is resistant to moisture, which is important in cold storage facilities where condensation can occur.

- Q: How does fiberglass mat tissue compare to other types of insulation materials?

- Fiberglass mat tissue offers several advantages over other types of insulation materials. Firstly, it has excellent thermal insulation properties, making it highly effective in reducing heat transfer and maintaining a comfortable indoor environment. Additionally, fiberglass mat tissue is lightweight, easy to handle, and can be easily installed in various applications, such as walls, roofs, and floors. It is also resistant to moisture, mold, and pests, ensuring long-lasting performance and durability. Moreover, fiberglass mat tissue is cost-effective and provides great value for money due to its high efficiency and low maintenance requirements. Overall, fiberglass mat tissue stands out as a reliable and efficient insulation material in comparison to others available in the market.

- Q: How does fiberglass mat tissue perform in terms of moisture resistance?

- Renowned for its exceptional resistance to moisture, fiberglass mat tissue is composed of tightly woven strands of fiberglass that form a formidable barrier against the infiltration of water. This remarkable feature renders it highly efficient in thwarting the permeation of water or moisture, thus safeguarding the integrity of underlying surfaces and structures. Furthermore, the incorporation of resin as a binding agent among the fiberglass strands offers an additional safeguard against moisture, augmenting its ability to withstand water and humidity. Consequently, fiberglass mat tissue emerges as a dependable option for moisture resistance, rendering it ideal for a wide range of applications where the prevention of water damage is of utmost importance.

- Q: What is the moisture absorption rate of fiberglass mat tissue?

- The moisture absorption rate of fiberglass mat tissue is relatively low, as fiberglass is known for its water-resistant properties.

- Q: Can fiberglass mat tissue be used for insulating crawl spaces?

- Indeed, one can utilize fiberglass mat tissue to insulate crawl spaces. This material, widely employed for insulation objectives, proves to be versatile. It boasts a lightweight composition that enables flexibility and easy installation, rendering it appropriate for crawl spaces that typically present restricted access and cramped corners. Moreover, fiberglass mat tissue showcases resistance against moisture, mold, and pests, making it an optimal selection for crawl spaces that frequently encounter these complications. Adding to its appeal, it exhibits exceptional thermal insulation properties, thereby promoting steady temperature maintenance and energy efficiency within the crawl space. All in all, fiberglass mat tissue proves itself to be a dependable and efficient choice for crawl space insulation.

- Q: Glass fiber cotton or ceramic fiber paper insulation?

- When the temperature can be met, the glass fiber cotton insulation is better. The main advantage of ceramic fiber is to make gaskets and the like

- Q: What is the chemical resistance of fiberglass mat tissue?

- Fiberglass mat tissue exhibits excellent chemical resistance due to the inherent properties of the fiberglass material. The mat tissue is typically composed of glass fibers that are woven or bound together, providing a barrier against a wide range of chemicals. The glass fibers themselves are highly resistant to corrosion, making fiberglass mat tissue suitable for use in environments where exposure to chemicals is a concern. The chemical resistance of fiberglass mat tissue can vary depending on the specific resin or binder used in the manufacturing process. Different types of resins may provide enhanced resistance to certain chemicals, while others may be more susceptible to degradation. It is important to consider the specific chemicals that will come into contact with the fiberglass mat tissue and select a resin or binder that is compatible with those substances. In general, fiberglass mat tissue is known for its resistance to acids, alkalis, solvents, and many other chemicals commonly found in industrial and commercial settings. It can withstand exposure to a wide range of corrosive substances, making it a versatile and durable material for various applications. However, it is worth noting that prolonged exposure to highly concentrated or aggressive chemicals may eventually cause some degradation or deterioration of the fiberglass mat tissue. Therefore, it is essential to consult the manufacturer's specifications and guidelines to ensure proper chemical compatibility and performance in specific environments.

- Q: Can fiberglass mat tissue be used for insulating metal roofs?

- Yes, fiberglass mat tissue can be used for insulating metal roofs. It provides a layer of insulation that helps to regulate temperature and minimize heat transfer, making it suitable for insulating metal roofs.

- Q: Can fiberglass mat tissue be used for repairing fiberglass RVs?

- Fiberglass mat tissue is a suitable option for fixing fiberglass RVs. This lightweight and flexible material is commonly employed to strengthen and mend fiberglass structures. Its design allows for easy molding and shaping to conform to the contours of the damaged area, making it an excellent choice for repairing RVs with curved surfaces. To repair a fiberglass RV using fiberglass mat tissue, you must first clean and prepare the damaged area. This involves removing any loose or damaged fiberglass. Next, you cut the mat tissue to the appropriate size and shape, ensuring it covers the damaged area completely. Apply a suitable fiberglass resin or adhesive to both the damaged area and the backside of the mat tissue. Carefully place the tissue over the damaged area, pressing it down firmly to ensure proper adhesion. Once the repair is finished, allow the fiberglass resin or adhesive to cure according to the manufacturer's instructions. After curing, you can sand, prime, and paint the repaired area to match the rest of the RV's exterior. It's crucial to note that fiberglass mat tissue is typically used for smaller repairs and cosmetic damage. For more extensive structural repairs, additional reinforcement materials such as fiberglass cloth or woven roving may be necessary. It is highly recommended to consult a professional or refer to specific repair guides for detailed instructions on repairing fiberglass RVs.

Send your message to us

Fiberglass Multiaxial Fabric-UD 600gsm for wind power industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords