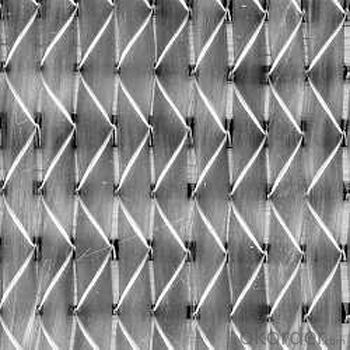

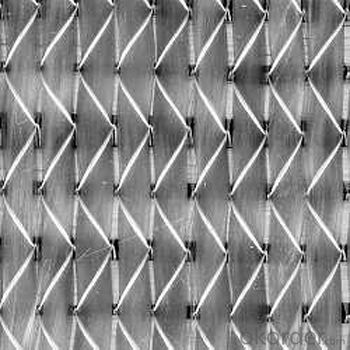

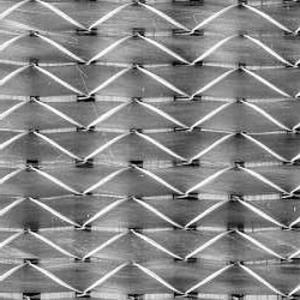

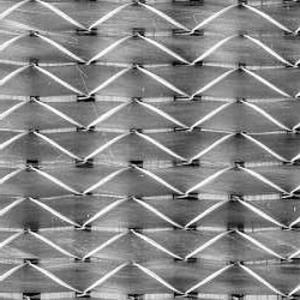

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series (0° or 90°) 450/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

1. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

2. What is your MOQ?

Our MOQ is one pallet.

3. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

- Q: What is the impact resistance of fiberglass mat tissue?

- The impact resistance of fiberglass mat tissue is generally high due to the reinforcing properties of the fiberglass strands, which help to absorb and distribute impact forces.

- Q: Is fiberglass mat tissue resistant to alkalis?

- Yes, fiberglass mat tissue is resistant to alkalis.

- Q: Can fiberglass mat tissue be used for mold-making?

- Typically, fiberglass mat tissue is not used for mold-making. This lightweight material is made up of randomly oriented glass fibers that are bonded together with a binder. It is commonly utilized in the insulation, construction, and automotive industries for reinforcement purposes. When it comes to mold-making, other materials like silicone, latex, or polyurethane are more commonly employed. These materials possess the necessary properties to create molds that are flexible and capable of reproducing intricate details accurately. Moreover, they are user-friendly and can be poured or brushed onto the original object to form a mold. Conversely, fiberglass mat tissue lacks the flexibility and accuracy required for mold-making. It is not designed to easily conform to complex shapes or capture fine details. Additionally, it may not provide the desired level of flexibility needed to safely remove the original object from the mold without causing damage. Therefore, it is advisable to utilize specific mold-making materials that are specifically designed for this purpose instead of attempting to employ fiberglass mat tissue.

- Q: Is fiberglass mat tissue compatible with different resin systems?

- Yes, fiberglass mat tissue is compatible with different resin systems. Fiberglass mat tissue is a versatile material that can be used with various types of resin systems, including polyester, epoxy, and vinyl ester resins. It has excellent wet-out properties, meaning that it can easily absorb and distribute the resin evenly throughout the mat. This compatibility allows for the creation of strong and durable composite structures in a wide range of applications such as automotive, marine, construction, and aerospace industries. However, it is important to consider the specific properties and characteristics of the resin system being used in order to ensure optimal performance and compatibility with the fiberglass mat tissue.

- Q: How is fiberglass mat tissue used in the production of chemical reactors?

- Due to its exceptional properties, fiberglass mat tissue is commonly utilized in the production of chemical reactors. Composed of randomly oriented glass fibers bonded together with a binder material, this tissue is ideal for constructing these reactors. A primary application of fiberglass mat tissue in chemical reactors is as a reinforcement material. It is typically applied to the inner surfaces of the reactor to enhance its structural integrity. The combination of glass fibers and binder creates a durable and strong layer capable of withstanding harsh conditions within the reactor, such as high temperatures and corrosive chemicals. Moreover, fiberglass mat tissue acts as a protective barrier against chemical attack. Traditional materials often degrade when exposed to aggressive substances found in chemical reactors. However, the chemical resistance of fiberglass mat tissue makes it highly suitable for such environments. It effectively prevents corrosive chemicals from penetrating the reactor walls, ensuring the long-lasting reliability of the equipment. Additionally, fiberglass mat tissue offers thermal insulation properties to chemical reactors. This is particularly crucial in processes where temperature control is vital. The insulation capabilities of the tissue help maintain the desired temperature within the reactor, preventing heat loss or gain that could negatively impact the efficiency and consistency of chemical reactions. In conclusion, fiberglass mat tissue plays a vital role in the production of chemical reactors by reinforcing the structure, providing chemical resistance, and offering thermal insulation. Its unique properties make it an excellent choice for ensuring the durability, safety, and optimal performance of chemical reactors in various industrial applications.

- Q: What are the applications of fiberglass mat tissue?

- Fiberglass mat tissue is a versatile material that finds numerous applications across various industries. Some of the key applications of fiberglass mat tissue are: 1. Construction and Building Materials: Fiberglass mat tissue is widely used in the construction industry as a reinforcement material. It is commonly used in the manufacturing of roofing shingles, insulation materials, and wall coverings. The strong and durable nature of fiberglass mat tissue enhances the structural integrity of buildings and improves their resistance to external elements such as wind, moisture, and temperature changes. 2. Automotive Industry: Fiberglass mat tissue is extensively used in the automotive sector for manufacturing various components such as door panels, headliners, trunk liners, and interior trim parts. The lightweight and high strength properties of fiberglass mat tissue make it an ideal material for reducing the overall weight of vehicles while maintaining their structural integrity. 3. Marine Industry: Fiberglass mat tissue is widely used in the marine industry for the production of boat hulls, decks, and other structural components. The corrosion-resistant nature of fiberglass mat tissue makes it suitable for marine applications where exposure to water and harsh weather conditions is common. 4. Pipe Manufacturing: Fiberglass mat tissue is used in the production of fiberglass reinforced pipes. These pipes find applications in various industries such as oil and gas, chemical, and water management. The high strength and corrosion-resistant properties of fiberglass mat tissue make it an excellent choice for manufacturing pipes that can withstand high pressure and harsh chemical environments. 5. Filtration Systems: Fiberglass mat tissue is used in the production of air filters and liquid filtration systems. The fibrous structure of the material allows for efficient filtration by trapping dust particles, dirt, and other contaminants. This makes fiberglass mat tissue a preferred choice for applications requiring high-efficiency filtration, such as HVAC systems, industrial air filters, and water treatment plants. Overall, the applications of fiberglass mat tissue are vast and diverse, ranging from construction and automotive industries to marine and filtration systems. Its unique properties make it an invaluable material for enhancing structural integrity, reducing weight, and improving performance across various sectors.

- Q: How does fiberglass mat tissue enhance the strength of composite materials?

- Fiberglass mat tissue plays a crucial role in enhancing the strength of composite materials. It is a woven fabric made of thin fiberglass strands, which are randomly oriented and bonded together with a resin binder. This unique structure allows the fiberglass mat tissue to provide several key benefits to composite materials. Firstly, the random orientation of the fiberglass strands in the mat tissue helps distribute the stress and load more evenly across the composite material. This means that when a force is applied to the composite, the mat tissue prevents localized stress concentrations, which can lead to cracks or failure. By distributing the stress, the fiberglass mat tissue enhances the overall strength and durability of the composite material. Secondly, the resin binder used in the fiberglass mat tissue acts as a reinforcement and bonding agent. When the composite material is manufactured, the resin binder in the mat tissue infiltrates the fibers, creating a strong and cohesive structure. This not only improves the overall strength of the composite material but also enhances its resistance to impact and fatigue. Furthermore, the presence of the fiberglass strands in the mat tissue increases the stiffness of the composite material. The strands, when combined with the resin binder, create a rigid framework that adds structural integrity to the composite. This increased stiffness makes the material more resistant to deformation and improves its load-bearing capabilities. In addition to strength enhancement, fiberglass mat tissue also provides thermal and electrical insulation properties to composite materials. The fiberglass strands act as a barrier, reducing heat transfer and preventing electrical conductivity. This makes the composite material suitable for applications where insulation is required, such as in electrical enclosures or thermal insulation panels. Overall, fiberglass mat tissue plays a vital role in enhancing the strength of composite materials by distributing stress, reinforcing the structure, increasing stiffness, and providing additional insulation properties. Its random orientation, resin binder, and unique characteristics make it an indispensable component in the production of high-performance composites used in various industries, including aerospace, automotive, construction, and marine.

- Q: Is fiberglass mat tissue water-resistant?

- Yes, fiberglass mat tissue is water-resistant. Fiberglass is a material composed of fine fibers of glass, which are woven together to form a mat. This mat is then coated with a water-resistant material, such as a resin or gel coat, to enhance its water resistance. The water-resistant coating prevents water from seeping into the fiberglass mat, making it suitable for various applications where exposure to water or moisture is expected, such as in boat hulls, shower stalls, and outdoor furniture. However, it is important to note that while fiberglass mat tissue is water-resistant, it is not completely waterproof. It may still absorb small amounts of water over time if not properly maintained or if exposed to prolonged and excessive moisture.

- Q: What are the different color options available for fiberglass mat tissue?

- Various color options are offered for fiberglass mat tissue, catering to different preferences and applications. White, gray, black, and beige are among the commonly available colors. These color choices offer versatility in design and aesthetics, allowing users to select a color that enhances their individual project needs. Factors like UV resistance and desired visibility or camouflage levels can also influence the color selection. In conclusion, the availability of diverse color options for fiberglass mat tissue grants users the flexibility and customization opportunities necessary to achieve their desired results.

- Q: Can fiberglass mat tissue be used for reinforcing concrete structures?

- Yes, fiberglass mat tissue can be used for reinforcing concrete structures. It provides additional strength and durability to the concrete, enhancing its resistance to cracking and improving its overall structural integrity.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series (0° or 90°) 450/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords