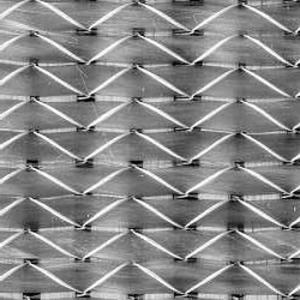

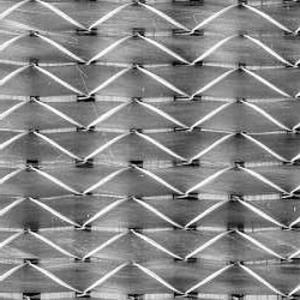

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series (0° or 90°) 500/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes. ◎ It’s compatible with UP, Vinyl Ester and Epoxy etc, used in GRP pultrusion process, hand lay-up process and RTM process etc, out-made products include GRP boats, automobile parts, wind energy blades etc.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

1) which kind of glass fiber sample and materials can you provide?

We can provide the glass fiber and glass fiber down stream products samples of E glass, C glass, ECR glass, High alkali glass. The products includes single end roving, assembled roving for different applications( Piping, SMC, panel, winding mill plate) , chop strand for BMC, engineering plastic (PA, PPA, PPT, POM, etc), chop strand mat (from 100gsm-900gsm) for automobile and water tank, etc, woven roving (270gsm-800gsm), surface tissue (25-50gsm), multi-axial fabric of different unit weight.

2) Can you provide glass fiber composite material?

We can provide GFRP profile such as grating, T beam, U beam and other assembles pieces such as GFRP triangle frame, dust bin, fireplace, etc

3) How much sample can you provide and who will bear the sample cost?

We can provide the glass fiber samples not more than 1kg free of change. However, the courier cost must be born by the customer. As to the glass fiber composite materials, we can provide the piece not more than 1kg free of change ( with the existing module). However, the courier cost must be born by the customer. If we need to make a new model, this excludes.

4) How can you guarantee the quality?

We only provide the materials that have been approved by many customers and little claim or no claim on it. We have signed the obligation contract with the manufacturer. If the few quality issue happened, we can work with the manufacturer to solve it and customer’s benefit can be guaranteed.

- Q: Is fiberglass mat tissue easy to install?

- Installing fiberglass mat tissue is relatively easy. This lightweight and flexible material can be easily cut and shaped to fit any surface. It can be applied using different methods, including spraying, rolling, or brushing on adhesive. Moreover, the tissue is self-adhesive, which simplifies the installation process as it readily adheres to the desired surface. Additionally, fiberglass mat tissues are generally designed to resist water and offer excellent insulation, making them a favored choice for various applications. In conclusion, by adequately preparing and following the manufacturer's guidelines, installing fiberglass mat tissue can be a simple and trouble-free task.

- Q: Can fiberglass mat tissue be used for pipe insulation?

- Typically, pipe insulation does not involve the use of fiberglass mat tissue. Fiberglass mat tissue is a thin substance commonly utilized for reinforcement in different industries, rather than for thermal insulation or preventing heat loss in pipes. When it comes to insulating pipes, materials like foam, mineral wool, or fiberglass pipe insulation are more commonly employed. These materials are specifically designed to offer thermal insulation and safeguard pipes against heat loss, condensation, and freezing.

- Q: How does the weight of fiberglass mat tissue affect its performance?

- The weight of fiberglass mat tissue directly affects its performance as a lighter tissue allows for better flexibility and ease of handling, while a heavier tissue provides increased strength and durability.

- Q: Can fiberglass mat tissue be used for repairing fiberglass boats?

- Yes, fiberglass mat tissue can be used for repairing fiberglass boats. It is commonly used in boat repairs to reinforce weak or damaged areas and provide strength and durability to the repaired sections.

- Q: What are the different types of fiberglass mat tissue available?

- A variety of fiberglass mat tissues can be found, each possessing its own distinct qualities and uses. Some commonly encountered types include the following: 1. Chopped Strand Mat (CSM): This is the most widely utilized and fundamental kind of fiberglass mat tissue. It comprises randomly arranged chopped fiberglass strands held together by a binder. CSM is commonly employed in situations where strength and resilience are crucial, such as in the construction of boats and automotive components. 2. Continuous Filament Mat (CFM): Unlike CSM, CFM is fashioned from continuous fiberglass strands woven into a mat. This type of fiberglass mat tissue offers exceptional tensile strength and dimensional stability, making it ideal for applications necessitating high strength and stiffness, such as in aerospace components and wind turbine blades. 3. Surface Veil Mat: Surface veil mat is an extremely thin and lightweight fiberglass mat tissue primarily used for surface finishing and reinforcement. It is typically applied as a final layer in composite laminates to enhance surface smoothness and water resistance. 4. Stitched Mat: Stitched mat is produced by interweaving continuous fiberglass strands with stitching thread. This construction yields enhanced strength and improved drapability, facilitating easier conformity to complex shapes. Stitched mat is commonly utilized in applications necessitating a blend of strength and flexibility, such as in the production of pipes and tanks. 5. Binderless Mat: Binderless mat is a specialized kind of fiberglass mat tissue that lacks binders or resins. Instead, the fibers are mechanically bonded through a needling process. This renders binderless mat highly resistant to chemical attack and suitable for use in corrosive environments, such as chemical storage tanks and pipes. These examples merely touch upon the wide range of fiberglass mat tissues available. The selection of which type to employ hinges on the specific requirements of the application, encompassing factors such as strength, flexibility, surface finish, and resistance to various environmental influences.

- Q: Is fiberglass mat tissue fire resistant?

- Yes, fiberglass mat tissue is fire resistant.

- Q: Can fiberglass mat tissue be used for repairing damaged fiberglass structures?

- Yes, fiberglass mat tissue can be used for repairing damaged fiberglass structures. The mat tissue is designed to provide strength and reinforcement to the damaged area, making it an effective solution for repairing fiberglass structures.

- Q: What is the expected lifespan of fiberglass mat tissue in cleanroom applications?

- Several factors can influence the expected lifespan of fiberglass mat tissue in cleanroom applications. The durability and long-lasting properties of fiberglass mat tissue are well-known in cleanrooms. However, variables such as contamination level, cleaning procedures, maintenance practices, and overall cleanroom conditions can impact its lifespan. By providing proper care and regular maintenance, fiberglass mat tissue can typically endure for several years in cleanroom applications. Extending its lifespan can be achieved through frequent cleaning and replacing any damaged or contaminated sections. Following the manufacturer's guidelines and recommendations for cleaning and maintenance is crucial to ensure optimal performance and longevity. Furthermore, the expected lifespan of fiberglass mat tissue can also be influenced by its quality and grade. Higher-quality materials exhibit greater resilience and can withstand environmental stressors better than lower-grade options. Therefore, investing in high-quality fiberglass mat tissue can contribute to a longer lifespan in cleanroom applications. To summarize, there is no definitive answer regarding the exact expected lifespan of fiberglass mat tissue in cleanroom applications. However, regular maintenance, proper care, and the use of high-quality materials can significantly increase its longevity.

- Q: Does fiberglass mat tissue require any special handling or storage requirements?

- Fiberglass mat tissue necessitates specific care and storage measures. To begin with, it is imperative to handle fiberglass mat tissue delicately in order to prevent any harm or breakage. The tissue should be treated with gentleness and not pulled or dropped, as this may result in the separation or damage of the fibers. It is also advisable to wear gloves and protective clothing while handling fiberglass mat tissue to avoid any skin irritation or injuries. Regarding storage, it is crucial to keep fiberglass mat tissue in a clean and dry environment. Shielding it from moisture is of utmost importance, as water exposure can weaken the fibers and diminish its efficacy. Therefore, it is preferable to store fiberglass mat tissue in sealed, moisture-proof packaging or in a dry room with controlled humidity levels. Furthermore, fiberglass mat tissue should be kept away from direct sunlight and extreme temperatures. High temperatures can cause the resin in the tissue to cure prematurely, while excessive cold can make it brittle and more susceptible to damage. Hence, it is recommended to store fiberglass mat tissue in a cool and shaded area to maintain its quality and ensure its longevity. By adhering to these specialized handling and storage requirements, fiberglass mat tissue can be safeguarded and preserved in its optimal condition, ready for utilization in various industries such as construction, insulation, or automotive.

- Q: How does fiberglass mat tissue compare to cellulose insulation?

- Fiberglass mat tissue and cellulose insulation differ in terms of material composition and insulation properties. Fiberglass mat tissue is made from fine glass fibers, while cellulose insulation is composed of recycled paper fibers treated with fire-retardant chemicals. Fiberglass mat tissue offers higher R-value, meaning it provides better thermal insulation and energy efficiency. Additionally, it is resistant to moisture and does not promote mold growth. On the other hand, cellulose insulation is more affordable, environmentally friendly, and provides better sound insulation. Ultimately, the choice between the two depends on specific insulation needs, budget, and environmental considerations.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series (0° or 90°) 500/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords