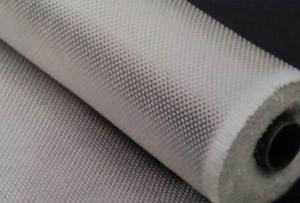

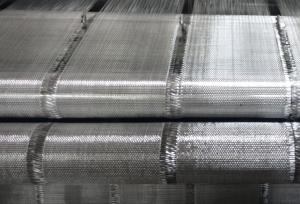

E Glass Fiber Woven Roving Mat For Boat Manufaturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

E-Glass Woven Rovings are bidirectional fabric made by interweaving direct rovings,which are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E-Glass Woven Rovings are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats and also can be used for vessels, plane and automotive parts, furniture and sports facilities.

2.Product Feature

Densely aligned fibers, resulting in high dimensional stability and making handling easy

Good moldability, fast and complete wet out in resins, resulting in high productivity

Good mechanical properties and high strength of parts

3.Technical Specifications

Property | Area Weight | Moisture Content | Size Content | Width |

(%) | (%) | (%) | (mm) | |

Test Method | IS03374 | ISO3344 | ISO1887 | |

EWR200 | ±7.5 | ≤0.15 | 0.4-0.8 | 20-3000 |

EWR270 | ||||

EWR300 | ||||

EWR360 | ||||

EWR400 | ||||

EWR500 | ||||

EWR600 | ||||

EWR800 |

4.FAQ

Packaging:

The woven roving roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper.

Storage:

Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Can fiberglass mat tissue be used for pipe insulation?

- Yes, fiberglass mat tissue can be used for pipe insulation. It provides thermal insulation and can help prevent heat loss or gain in pipes. Additionally, it offers excellent resistance to moisture and corrosion, making it suitable for various pipe insulation applications.

- Q: Can fiberglass mat tissue be used for HVAC insulation?

- No, fiberglass mat tissue is not suitable for HVAC insulation. It is primarily used for reinforcing materials in construction and composite manufacturing. HVAC insulation requires specific materials with thermal resistance properties to effectively control temperature and reduce energy loss.

- Q: Is fiberglass mat tissue suitable for marine applications?

- Fiberglass mat tissue is indeed appropriate for marine applications. Its durability, strength, and ability to resist water and corrosion make it a popular choice in the marine industry. This lightweight material is perfect for boat construction and repairs. It also offers exceptional resistance against UV rays, chemicals, and harsh weather conditions commonly found in marine environments. Additionally, it provides outstanding structural reinforcement and can be easily shaped and molded to suit different marine components. All in all, fiberglass mat tissue is a dependable and adaptable material for marine uses.

- Q: Is fiberglass mat tissue resistant to mold and mildew?

- Yes, fiberglass mat tissue is resistant to mold and mildew due to its non-porous and moisture-resistant properties.

- Q: What are the different finishing options available for fiberglass mat tissue?

- Fiberglass mat tissue offers a variety of finishing options to meet specific needs. One popular choice is applying a resin coating, which protects and strengthens the fibers while giving the material a smooth and glossy look. Another option is a fire-retardant treatment, which involves applying a special chemical to reduce flammability. This is crucial for industries where fire safety is a concern, like construction. Color customization is also possible by adding dye or pigment during manufacturing. This allows for a wide range of visually appealing options. For a more tactile and aesthetically pleasing product, a textured finish can be applied to the surface. This is useful in applications requiring grip or slip resistance. Lastly, a laminated backing can be used to bond the fiberglass mat tissue to materials like foam or fabric, adding strength and flexibility. In summary, fiberglass mat tissue offers various finishing options to enhance its performance and appearance in different industries. The ability to customize strength, fire resistance, color, texture, and backing makes it a versatile choice.

- Q: What is the shelf life of fiberglass mat tissue?

- The shelf life of fiberglass mat tissue can vary depending on several factors such as storage conditions, packaging, and the specific manufacturer's recommendations. Generally, fiberglass mat tissue can have a shelf life of around one to two years if stored in a cool, dry place and unopened. However, it is important to note that over time, the material may degrade or lose its physical properties, which can affect its performance and suitability for use. Therefore, it is advisable to always check the manufacturer's guidelines or consult with them directly for the most accurate information regarding the shelf life of a particular fiberglass mat tissue product.

- Q: Can fiberglass mat tissue be used for repairing fiberglass fenders?

- Fiberglass fenders can be repaired using fiberglass mat tissue. This versatile material is commonly employed in fiberglass repair tasks, serving as a reinforcement layer to enhance strength and durability in the repaired region. To mend damaged or cracked areas of fiberglass fenders, one can apply a resin layer and then lay the fiberglass mat tissue on top. By saturating the mat tissue with additional resin, a strong bond is formed, ensuring a smooth finish. This restorative process not only revitalizes the fender's structural integrity but also delivers a seamless repair. It is worth noting, however, that the extent of the damage and the expertise of the repairer ultimately determine the success of the repair.

- Q: Is the Teflon gasket filled with fiberglass or graphite?

- PTFE itself has the effect of self lubrication, you can ask the production of PTFE can add these, should not be able to! Vespel can add graphite to increase self lubrication

- Q: Can fiberglass mat tissue be used for making boat hulls?

- Yes, fiberglass mat tissue can be used for making boat hulls. Fiberglass mat tissue is a lightweight and strong material that is commonly used in boat building and repair. It is made by bonding strands of fiberglass together with a binder, resulting in a flexible mat that can be easily formed and molded into various shapes. Boat hulls require a material that is durable, water-resistant, and has good structural integrity, all of which fiberglass mat tissue provides. Additionally, fiberglass mat tissue is relatively easy to work with and can be layered to increase its strength as needed. Therefore, it is a popular choice for constructing boat hulls.

- Q: Can fiberglass mat tissue be used for interior decoration?

- Yes, fiberglass mat tissue can be used for interior decoration. It is commonly used as a reinforcement material in wall coverings, ceiling tiles, and other decorative elements. Its durability, fire resistance, and versatility make it suitable for various interior design applications.

Send your message to us

E Glass Fiber Woven Roving Mat For Boat Manufaturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords