Fiberglass Mat Tissue - Multiaxial Fabric-UD Series (0° or 90°) 600/50g

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Fiberglass Multiaxial Fabric-UD Description:

An engineering material, which has many excellent characterstics, such as anti-burning, corrosion resistent, stable structure, heat-isolating, minimum elongated shrinkage, high intensity, etc. This new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc. According to fabric organizational structure and appearance, there are such kind of products: plain weave, twill weave, satin weave, gauze weave.

Main Features of the Fiberglass Multiaxial Fabric-UD:

1)Plain veave,even thickness and low fuzz;

2)High strength in both warp and weft direction;

3)Incombustibility,corrosion resistance and heat resistance;

4)E-Grade Fabric (E-fiberglass Textile Cloth) has excellent electricity insulation property.

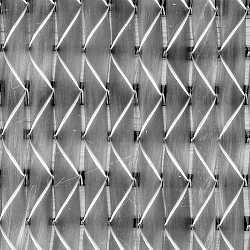

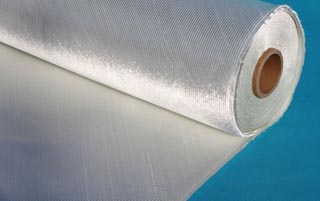

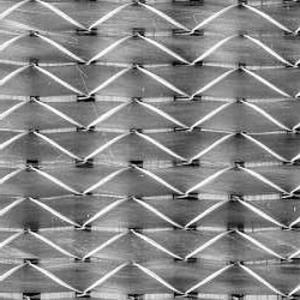

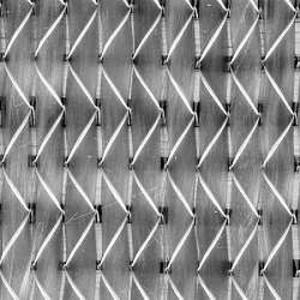

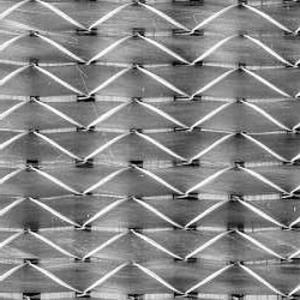

Fiberglass Multiaxial Fabric-UD Images:

Unidirectional Specification:

Code | Total weight g/m2 | Weight of each layer, g/m2 | Width mm | ||||

0° | 90° | +45° | -45° | Chopping | |||

E-L300 | 350 | 300 | 50 | 200~2600 | |||

E-L350 | 400 | 350 | 50 | 200~2600 | |||

E-L400 | 450 | 400 | 50 | 200~2600 | |||

E-L450 | 500 | 450 | 50 | 200~2600 | |||

E-L500 | 550 | 500 | 50 | 200~2600 | |||

E-L600 | 650 | 600 | 50 | 200~2600 | |||

E-L650 | 700 | 650 | 50 | 200~2600 | |||

E-L900 | 930 | 880 | 50 | 200~2600 | |||

E-L700/200 | 950 | 700 | 50 | 200 | 200~2600 | ||

E-T200 | 200 | 200 | 200~2600 | ||||

E-T450 | 450 | 450 | 200~2600 | ||||

E-T500 | 500 | 500 | 200~2600 | ||||

E-TM300/300 | 600 | 300 | 300 | 200~2600 | |||

E-TM600/450 | 1050 | 600 | 450 | 200~2600 | |||

E-LM750/200 | 950 | 750 | 200 | 200~2600 | |||

FAQ of Chopped strand mat

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: What is fiberglass mat tissue?

- Fiberglass mat tissue, made from randomly oriented glass fibers bonded together with a binder, is a non-woven material used in construction, automotive, and aerospace industries. The primary function of fiberglass mat tissue is to reinforce and provide strength and durability to composite materials. It acts as a supportive layer between the glass fibers and resin, distributing stress and improving mechanical properties. Fiberglass mat tissue offers several advantages. It is lightweight, flexible, and easy to handle, making it suitable for complex shapes and curved surfaces. It also has excellent resistance to chemicals, moisture, and temperature changes, ensuring longevity in harsh environments. In construction, fiberglass mat tissue is commonly used in roofing materials, wall panels, and insulation boards. Its high strength-to-weight ratio makes it ideal for reinforcing concrete structures like bridges and buildings. In the automotive industry, fiberglass mat tissue enhances the structural integrity of car parts such as body panels, bumpers, and interior components, making them more resistant to impacts and vibrations. In aerospace, fiberglass mat tissue is utilized in the production of aircraft components like wings, fuselages, and interiors. Its lightweight nature contributes to fuel efficiency and weight reduction while maintaining necessary strength for safe flight. Overall, fiberglass mat tissue is a versatile and reliable material that plays a crucial role in enhancing the performance, durability, and safety of various products across industries. Its unique properties make it an indispensable component in the production of composite materials.

- Q: Does fiberglass mat tissue require any special curing conditions?

- Yes, fiberglass mat tissue does require special curing conditions. It typically needs to be cured at specific temperature and humidity levels for a specific duration of time in order to achieve optimal strength and performance.

- Q: How does fiberglass mat tissue perform in terms of heat insulation?

- Fiberglass mat tissue performs relatively well in terms of heat insulation. Due to its composition of fine glass fibers and a binder, it has good thermal resistance properties. These fibers trap air pockets, which act as thermal barriers by reducing heat transfer. This makes fiberglass mat tissue a suitable insulation material for various applications, such as in the construction industry for insulating walls, roofs, and attics. Additionally, fiberglass mat tissue is also commonly used in automotive and aerospace industries to insulate engine compartments and reduce heat transfer through vehicle panels, respectively. However, it is important to note that while fiberglass mat tissue provides excellent thermal insulation, it may not be as effective as some other insulation materials, such as foam or mineral wool, which have higher thermal resistance values. Overall, fiberglass mat tissue is a reliable option for heat insulation, but the specific requirements of the project should be considered to determine the most suitable insulation material.

- Q: What is the maximum temperature resistance of fiberglass mat tissue?

- The maximum temperature resistance of fiberglass mat tissue typically ranges between 300-600 degrees Celsius, depending on the specific composition and quality of the material.

- Q: Is fiberglass mat tissue resistant to termites and insects?

- Generally, termites and insects do not pose a threat to fiberglass mat tissue. This is because fiberglass is made from woven glass fibers, which are not a preferred food source for termites or insects. Furthermore, a layer of resin is typically applied to fiberglass mat tissue, further enhancing its resistance to pests. As a result, fiberglass mat tissue is a popular choice for construction and insulation in areas prone to termite and insect infestations. However, it is important to note that although fiberglass mat tissue itself is resistant to termites and insects, it does not provide complete protection against infestations. Therefore, it is advisable to implement additional measures such as proper sealing and regular inspections to ensure effective long-term pest control.

- Q: Can fiberglass mat tissue be used for insulation in research laboratories?

- Yes, fiberglass mat tissue can be used for insulation in research laboratories. Fiberglass mat tissue is a common material used for thermal and acoustic insulation due to its excellent insulation properties. It is highly resistant to heat, moisture, and chemicals, making it suitable for laboratory settings. Additionally, fiberglass mat tissue is lightweight and easy to install, allowing for quick and efficient insulation in research laboratories. Its low thermal conductivity helps to maintain stable temperature conditions, ensuring optimal conditions for experiments and reducing energy consumption. Therefore, fiberglass mat tissue is a viable choice for insulation in research laboratories.

- Q: What is the maximum temperature that fiberglass mat tissue can withstand?

- The maximum temperature that fiberglass mat tissue can withstand depends on the specific type of fiberglass material being used. Generally, most fiberglass mat tissues are designed to withstand temperatures up to 600 degrees Fahrenheit (315 degrees Celsius). However, it is important to note that the temperature tolerance can vary depending on factors such as the thickness of the material, the manufacturing process, and the specific application. It is always advisable to consult the manufacturer's specifications or technical data sheets for accurate information regarding the maximum temperature resistance of a particular fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for insulation in hot climates?

- Yes, fiberglass mat tissue can be used for insulation in hot climates. It has excellent thermal insulation properties and can effectively block heat transfer, making it suitable for use in hot climates to maintain cooler indoor temperatures.

- Q: Can fiberglass mat tissue be used in marine applications?

- Certainly! Fiberglass mat tissue finds its utility in the realm of marine applications. It is a lightweight and flexible substance that is extensively employed in the construction and repair of boats. Its commendable strength and durability render it suitable for marine environments that entail exposure to water, salt, and other severe conditions. It is frequently employed as a reinforcement layer in the fabrication of boat hulls, decks, and other structural constituents. Its incorporation augments the strength and rigidity of composite materials employed in marine applications, thus bolstering their overall performance and lifespan. Furthermore, fiberglass mat tissue exhibits resistance to corrosion and possesses favorable water resistance properties, rendering it an apt choice for marine applications.

- Q: Can fiberglass mat tissue be painted over?

- Yes, fiberglass mat tissue can be painted over. However, it is important to properly prepare the surface before painting by cleaning and sanding it to ensure good adhesion of the paint. Additionally, it is recommended to use a primer specifically designed for fiberglass surfaces to enhance the paint's durability and appearance.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series (0° or 90°) 600/50g

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords