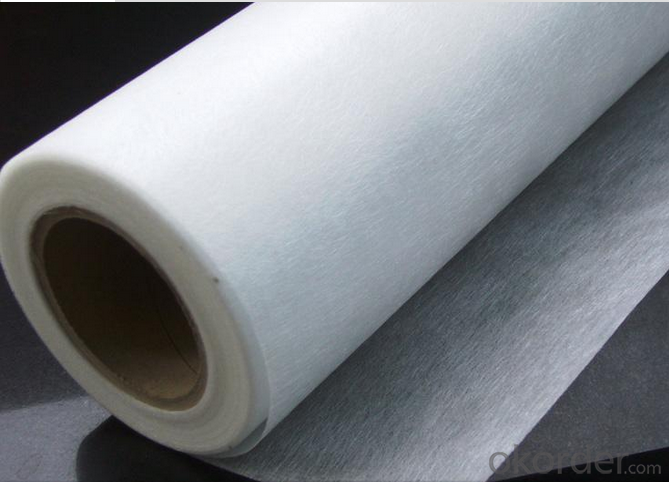

Fiberglass Mat Tissue e-glass Fiber Surface Tissuing Mat for GRP

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 72000 m²

- Supply Capability:

- 1440000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Surfacing Tissue mainly used in the surface layers of FRP products. It features even Fiber distribution, soft feel, level and smooth fiber surface, less glue content, quick resin soak and good pattern fitness. It can improve the product surface property on corrosion resistance, compressive strength, seepage resistance, and longer service life. It is also suitable for spraying; pattern pressing and other FRP pattern technology.

Product Features:

Fast breakdown in styrene

Fiber dispersed evenly

Low binder content

Superior acid corrosion resistance

Specifications:

Item | Unit | Specification |

Area Weight | g/m2 | 30+/-3 |

Binder Content | % | 6-9 |

Tensile Strength MD | N/125px | ≥35 |

Soaking time | S | ≤10 |

Moisture content | % | ≤0.5 |

Width length

| mm

| 1270

|

Roll Diameter

| m | 300

|

Paper Core Internal Dia | mm | 76 |

Special specification can be produce according to customer requirements.

Product packaging:

Each Surface Tissue is wound onto a paper tube The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Product storage:

Unless otherwise specified, Chopped Strand Mat should be stored in a dry, cool and rain-proof area.

- Q: Is fiberglass mat tissue suitable for wind energy applications?

- Indeed, fiberglass mat tissue proves to be a fitting choice for wind energy applications. This lightweight and resilient material is often employed in the fabrication of wind turbine blades. It possesses remarkable strength and rigidity, rendering it well-suited to endure the formidable strains and pressures exerted on wind turbines. Furthermore, fiberglass mat tissue exhibits resistance against corrosion and deterioration caused by UV radiation, thereby guaranteeing the durability and functionality of wind turbine blades. In summary, the integration of fiberglass mat tissue into wind energy applications enables the creation of efficient and dependable wind turbines capable of generating clean and sustainable energy.

- Q: How is fiberglass mat tissue used in the production of windshields?

- Fiberglass mat tissue is a crucial component in the production of windshields due to its unique properties and functions. When manufacturing windshields, the fiberglass mat tissue is used as a reinforcement material to enhance the strength and durability of the glass. During the production process, a layer of fiberglass mat tissue is inserted between two layers of glass to create a laminated structure. This layer acts as a barrier, preventing the glass from shattering into small dangerous pieces upon impact. It helps to hold the glass together, providing safety to the vehicle occupants. The fiberglass mat tissue serves as a reinforcing material, improving the mechanical properties of the windshield. It enhances the impact resistance, making the windshield less prone to cracks or chips from stones, debris, or other objects that may hit it while driving. This reinforcement also adds structural integrity to the windshield, allowing it to withstand extreme weather conditions and vibrations without compromising its functionality. Furthermore, the fiberglass mat tissue helps to reduce noise transmission and vibrations. It has sound-damping properties, which contribute to a quieter and more comfortable driving experience by reducing external noise from entering the vehicle cabin. Additionally, the use of fiberglass mat tissue allows for the production of curved windshields. The flexibility of the material enables it to conform to different shapes and contours, allowing manufacturers to create windshields with customized designs and improved aerodynamics. In summary, fiberglass mat tissue plays a vital role in the production of windshields. Its reinforcement properties enhance the strength and impact resistance of the glass, providing safety to the vehicle occupants. It also contributes to a quieter driving experience and enables the production of curved windshields with improved aerodynamics.

- Q: How does the thickness of fiberglass mat tissue affect its flexibility?

- The thickness of fiberglass mat tissue typically has an inverse relationship with its flexibility. As the thickness of the mat tissue increases, its flexibility decreases. Thicker mat tissues are stiffer and less pliable, making them less flexible compared to thinner ones.

- Q: What is the typical width of fiberglass mat tissue rolls?

- The typical width of fiberglass mat tissue rolls can vary depending on the specific manufacturer and intended application. However, in the construction and insulation industries, fiberglass mat tissue rolls are commonly available in widths ranging from 1.22 meters (4 feet) to 2.44 meters (8 feet). These dimensions are often chosen to align with standard building materials and construction practices. It is important to note that there may be variations in width options depending on the region or supplier, so it is advisable to consult with the manufacturer or supplier for the specific width requirements for a particular project.

- Q: What is the maximum temperature resistance of fiberglass mat tissue?

- The maximum temperature resistance of fiberglass mat tissue typically ranges between 300-600 degrees Celsius, depending on the specific composition and quality of the material.

- Q: How is fiberglass mat tissue used in the production of shower enclosures?

- The production of shower enclosures commonly utilizes fiberglass mat tissue due to its exceptional properties and advantages. This thin and flexible material consists of fine glass fibers that are randomly distributed and bonded together with a resin binder. To strengthen and enhance the shower enclosure, fiberglass mat tissue is primarily used as a reinforcement material. It is applied to the enclosure's surface to improve its strength, durability, and resistance to cracking or breaking. Initially, the fiberglass mat tissue is cut and sized according to the specific dimensions of the shower enclosure. It is then carefully placed or applied onto the enclosure's surface, typically through a process known as hand lay-up or spray-up. The mat tissue is strategically positioned to cover critical areas requiring reinforcement, such as corners, edges, and joints. Once the mat tissue is in position, a resin, usually polyester or epoxy, is applied over it. The resin penetrates the fiberglass mat tissue and bonds with the fibers, creating a solid and sturdy composite structure. This combination of resin and fiberglass provides additional strength and stability to the shower enclosure, making it more resistant to impact, stress, and water or humidity. Additionally, fiberglass mat tissue also contributes to the overall appearance of the shower enclosure. It helps achieve a smooth and uniform surface finish, eliminating imperfections and creating an aesthetically pleasing look. The mat tissue can be easily molded or shaped to match different designs and styles, enabling manufacturers to produce shower enclosures of various shapes, sizes, and patterns. In conclusion, fiberglass mat tissue plays a crucial role in the production of shower enclosures by offering reinforcement, strength, durability, and aesthetic benefits. This versatile material enhances the overall performance and visual appeal of the enclosures, ensuring they can withstand daily use and maintain their quality over time.

- Q: Is fiberglass mat tissue resistant to mold and mildew?

- Yes, fiberglass mat tissue is resistant to mold and mildew due to its non-porous and moisture-resistant properties.

- Q: What is the delamination strength of fiberglass mat tissue?

- The delamination strength of fiberglass mat tissue refers to its ability to resist the separation or detachment of layers within the material. This strength is dependent on various factors such as the quality of the resin used, the thickness and density of the mat, and the manufacturing process. Fiberglass mat tissue is typically designed to have a high delamination strength to ensure its durability and structural integrity. The mat is composed of multiple layers of glass fibers held together by a binder or resin. The bonding between these layers is crucial in preventing delamination. The delamination strength of fiberglass mat tissue can be determined through various testing methods, such as the peel test, where the force required to separate the layers is measured. This test provides valuable information about the adhesive strength between the layers and helps in assessing the overall quality of the material. The delamination strength can vary depending on the specific application and requirements. For example, fiberglass mat tissue used in construction or automotive industries may have different delamination strength specifications compared to those used in marine or aerospace applications. Manufacturers typically provide technical data or specifications indicating the delamination strength of their fiberglass mat tissue products. It is important to note that the delamination strength of fiberglass mat tissue can be influenced by external factors such as exposure to extreme temperatures, moisture, or chemical substances. Therefore, proper installation, maintenance, and adherence to recommended usage guidelines are essential to maintaining the desired delamination strength and overall performance of the material.

- Q: Can fiberglass mat tissue be used for repairing automotive parts?

- Certainly, automotive parts can be repaired using fiberglass mat tissue. This versatile material is commonly employed to reinforce and repair various surfaces, including automotive components. It proves particularly valuable when restoring fiberglass parts such as car bodies and panels. Fiberglass mat tissue possesses a thin and flexible composition, comprised of randomly arranged fiberglass strands. This design enables easy molding and shaping to match the contours of the damaged automotive part. Typically, the mat tissue is applied alongside a resin like polyester or epoxy, which binds the fibers together, yielding a robust and enduring repair. When utilized for automotive repairs, fiberglass mat tissue offers numerous advantages. Firstly, its lightweight nature is crucial for maintaining the overall weight and balance of the vehicle. Furthermore, it exhibits resistance to corrosion and can withstand exposure to diverse weather conditions, rendering it suitable for all automotive repair applications. Moreover, fiberglass mat tissue is renowned for its high tensile strength, enabling it to endure the stresses and strains encountered during normal use of automotive parts. As a result, it becomes an ideal choice for fixing damaged or weakened areas, such as cracks, holes, or dents in car bodies or panels. In conclusion, fiberglass mat tissue is a highly effective option for repairing automotive parts, especially those constructed from fiberglass. Its versatility, lightweight composition, corrosion resistance, and high tensile strength make it an exceptional choice for restoring the structural integrity and appearance of damaged automotive components.

- Q: Can fiberglass mat tissue be used for making boat hulls?

- Fiberglass mat tissue is indeed suitable for the construction of boat hulls. This lightweight and robust material is widely employed in the boat-building and repairing industry. By combining fiberglass strands with a binder, a flexible mat is formed, allowing for easy shaping and molding into various forms. Boat hulls necessitate a sturdy, water-resistant material with excellent structural integrity, all of which fiberglass mat tissue offers. Moreover, this material is relatively easy to manipulate and can be layered to enhance its strength according to requirements. Consequently, it is a favored option for constructing boat hulls.

Send your message to us

Fiberglass Mat Tissue e-glass Fiber Surface Tissuing Mat for GRP

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 72000 m²

- Supply Capability:

- 1440000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords