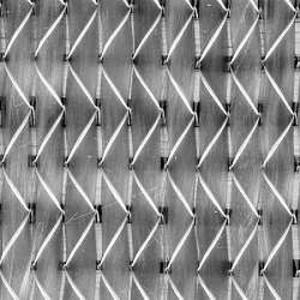

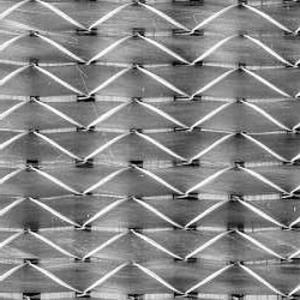

Fiberglass Mat Tissue - Multiaxial Fabric-UD (0°:700g, 90°:50g, Chopping:200g)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. ◎ Mechanical property of different directions is adjustable. ◎The multi-layers structure could simplify forming process, improve operation efficiency. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. Can you provide sample?

Yes, we can offer free sample for you.

- Q: What is the impact resistance of fiberglass mat tissue at high temperatures?

- The impact resistance of fiberglass mat tissue can vary at high temperatures, depending on factors like its specific composition, the manufacturing process, and the testing conditions. In general, fiberglass mat tissue has good impact resistance at high temperatures due to the inherent strength and durability of fiberglass materials. Fiberglass is recognized for its excellent mechanical properties, including high tensile strength and stiffness, which contribute to its overall impact resistance. Typically, fiberglass mat tissue maintains its structural integrity and can withstand impact without cracking or breaking at high temperatures. This is because the fiberglass fibers are designed to endure high temperatures and do not easily soften or deform. However, it's worth noting that the impact resistance of fiberglass mat tissue can be affected by other factors like the presence of additives or binders used during manufacturing. Some additives or binders may decrease impact resistance or make the tissue more prone to damage at high temperatures. To determine the specific impact resistance of a particular fiberglass mat tissue at high temperatures, it's crucial to refer to the manufacturer's specifications or conduct specific tests under controlled conditions. These tests can provide more precise information on how the material will perform under impact at elevated temperatures.

- Q: Does fiberglass mat tissue require any special surface bonding agents?

- Yes, fiberglass mat tissue often requires special surface bonding agents to ensure proper adhesion and bonding with the substrate. These agents help improve the overall strength and durability of the fiberglass mat tissue when applied to surfaces such as walls, floors, or other structures.

- Q: Can fiberglass mat tissue be used for repairing fiberglass shower stalls?

- Certainly! Fiberglass mat tissue is an excellent choice for fixing fiberglass shower stalls. It is a flexible material that is widely utilized for reinforcing and mending various fiberglass structures, such as shower stalls. Its purpose is to enhance the strength and resilience of the repaired section, guaranteeing a durable and dependable solution. By pairing fiberglass mat tissue with compatible fiberglass resin, one can effectively mend cracks, holes, and other impairments in fiberglass shower stalls. Nevertheless, it is vital to diligently adhere to the instructions and recommendations provided by the manufacturer to achieve optimal outcomes in terms of application and curing.

- Q: Is fiberglass mat tissue compatible with vacuum infusion processes?

- Yes, fiberglass mat tissue is compatible with vacuum infusion processes. It is commonly used in vacuum infusion techniques as it allows for the distribution of resin evenly throughout the laminate, resulting in a strong and uniform composite part.

- Q: Is fiberglass mat tissue suitable for aerospace applications?

- Yes, fiberglass mat tissue is suitable for aerospace applications. Fiberglass mat tissue is a lightweight material that exhibits excellent strength and durability, making it ideal for use in aerospace applications where weight reduction and structural integrity are critical. It is commonly used as a reinforcement material in composite structures and aerospace components such as wings, fuselages, and engine components. Fiberglass mat tissue provides high impact resistance, good thermal stability, and low moisture absorption, which are essential properties for withstanding the harsh conditions and extreme temperatures experienced in aerospace environments. Additionally, fiberglass mat tissue offers good electrical insulation properties, making it suitable for applications that require effective electrical shielding. Overall, fiberglass mat tissue is a reliable and widely used material in the aerospace industry due to its exceptional mechanical properties, lightweight nature, and ability to withstand the demanding conditions of aerospace applications.

- Q: Can fiberglass mat tissue be used for repairing fiberglass jet skis?

- Yes, fiberglass mat tissue can be used for repairing fiberglass jet skis. It is a common material used in fiberglass repairs, providing strength and reinforcement to the damaged area.

- Q: Can fiberglass mat tissue be used for making electrical enclosures?

- No, fiberglass mat tissue cannot be used for making electrical enclosures. Electrical enclosures require materials that have high electrical insulation properties, such as non-conductive plastics or metals, to ensure safety and prevent electrical hazards.

- Q: Can fiberglass mat tissue be used for making surfboards?

- Surfboards can indeed be made using fiberglass mat tissue. This material, known for its lightweight yet robust properties, is commonly utilized in constructing surfboards. Typically, it is combined with epoxy resin to form a sturdy and durable surface. By incorporating fiberglass mat tissue, surfboards gain the strength and flexibility necessary to endure the demanding conditions encountered while riding waves. Moreover, the smooth and sleek texture of the material enhances the surfboard's performance and speed. In summary, fiberglass mat tissue is a favored option for constructing high-performance surfboards due to its exceptional strength-to-weight ratio.

- Q: Is fiberglass mat tissue suitable for insulation in HVAC ducts?

- Yes, fiberglass mat tissue is suitable for insulation in HVAC ducts. Fiberglass is a commonly used material for insulation due to its excellent thermal and acoustic properties. It is capable of withstanding high temperatures and is resistant to moisture, making it ideal for ductwork applications. Fiberglass mat tissue provides effective insulation by reducing heat transfer and preventing condensation buildup within the ducts. Additionally, it is lightweight, easy to install, and has a long lifespan, making it a cost-effective choice for HVAC insulation. Overall, fiberglass mat tissue is a suitable and reliable option for insulation in HVAC ducts.

- Q: What are the different methods of bonding fiberglass mat tissue to other materials?

- There are various ways to bond fiberglass mat tissue to other materials, each with its own advantages and considerations. Some commonly used methods are as follows: 1. Mechanical Bonding: This technique involves physically interlocking the fiberglass mat tissue with the other material. It can be achieved through stitching, stapling, or using mechanical fasteners like screws or nails. While mechanical bonding provides a strong and durable connection, it may require additional hardware and can be time-consuming. 2. Adhesive Bonding: Adhesive bonding is a popular method that utilizes adhesives or glue to join the fiberglass mat tissue with the other material. This method offers flexibility, as there are different types of adhesives available for various applications. It is important to select an adhesive that is compatible with both the fiberglass mat tissue and the other material. Proper surface preparation and application techniques are crucial for achieving a strong bond. 3. Resin Infusion: Resin infusion involves infusing a liquid resin into the fiberglass mat tissue and other materials, resulting in a strong bond when cured. This method is commonly used in manufacturing composite products, as it allows for a seamless and uniform bond. Vacuum bagging or resin infusion techniques are typically employed to ensure proper resin distribution and consolidation. 4. Thermal Bonding: Thermal bonding employs heat to bond the fiberglass mat tissue to another material. This technique is particularly suitable for thermoplastic materials, as they can be softened and fused together with heat. Heat welding or ultrasonic welding are commonly used techniques for thermal bonding. Care must be taken to prevent damage or degradation of the fiberglass mat tissue during the bonding process. 5. Fusion Bonding: Fusion bonding is a method where the fiberglass mat tissue and the other material are heated to a molten state and then brought into contact to form a bond. This technique is commonly used in the manufacturing of thermosetting plastics or joining thermoplastic materials. Fusion bonding can provide a strong and seamless bond, but it requires precise control of temperature and pressure to ensure proper bonding without causing damage. To summarize, the various methods of bonding fiberglass mat tissue to other materials include mechanical bonding, adhesive bonding, resin infusion, thermal bonding, and fusion bonding. The choice of bonding method depends on factors such as the materials being bonded, the desired strength and durability, and the specific application requirements.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD (0°:700g, 90°:50g, Chopping:200g)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords