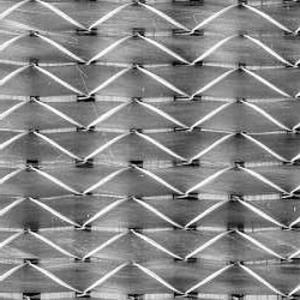

Fiberglass Mat Tissue - Multiaxial Fabric-UD (0° or 90°) 300/50g

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

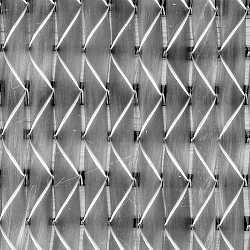

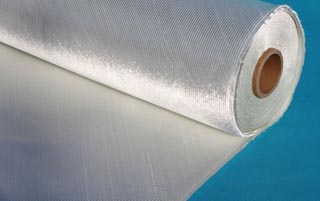

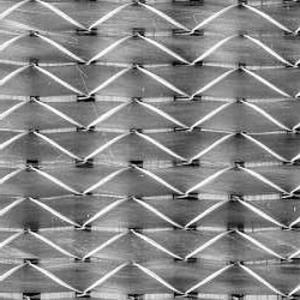

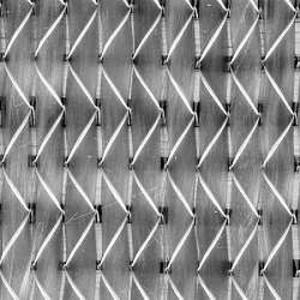

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: Can fiberglass mat tissue be used for composite pipe manufacturing?

- Yes, fiberglass mat tissue can be used for composite pipe manufacturing. Fiberglass mat tissue provides reinforcement to the composite pipe, enhancing its strength, durability, and resistance to corrosion.

- Q: How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue can have a significant impact on its transportation process. The weight of the roll determines the ease of handling and the logistics required for transportation. Firstly, a heavier roll weight can make it more challenging to move and handle the fiberglass mat tissue. If the roll is too heavy, it may require specialized equipment or machinery for loading and unloading, such as forklifts or cranes. This can add complexity and cost to the transportation process. Moreover, the weight of the roll also affects the packaging and storage requirements during transportation. Heavier rolls may require sturdier packaging materials and additional precautions to ensure their stability and prevent any damage during transit. This can include using pallets, strapping, or other securing methods to prevent the roll from shifting or falling during transportation. The weight of the roll also impacts the overall cost of transportation. Heavier rolls can increase shipping costs, as carriers often charge based on weight. Additionally, the weight of the roll can affect the number of rolls that can be transported in a single shipment, which can impact the efficiency and cost-effectiveness of the transportation process. In summary, the roll weight of fiberglass mat tissue plays a crucial role in its transportation. It affects the ease of handling, packaging requirements, and overall cost of transportation. Therefore, it is essential to consider the roll weight when planning and organizing the logistics for transporting fiberglass mat tissue.

- Q: Is fiberglass mat tissue suitable for insulation in chemical processing plants?

- Indeed, fiberglass mat tissue proves to be a suitable option for insulation within chemical processing plants. Comprised of delicate glass fibers securely bonded with a binder, it possesses remarkable thermal insulation characteristics. Its capability to endure elevated temperatures and its resistance against numerous chemicals render it an ideal selection for deployment in chemical processing plants, where contact with corrosive substances or intense heat may occur. Moreover, fiberglass mat tissue is lightweight and effortlessly installed, presenting a cost-effective solution for insulation in such industrial settings.

- Q: Is fiberglass mat tissue suitable for marine applications?

- Fiberglass mat tissue is indeed appropriate for marine applications. Its durability, strength, and ability to resist water and corrosion make it a popular choice in the marine industry. This lightweight material is perfect for boat construction and repairs. It also offers exceptional resistance against UV rays, chemicals, and harsh weather conditions commonly found in marine environments. Additionally, it provides outstanding structural reinforcement and can be easily shaped and molded to suit different marine components. All in all, fiberglass mat tissue is a dependable and adaptable material for marine uses.

- Q: Is fiberglass mat tissue suitable for insulation in laboratories?

- Fiberglass mat tissue is indeed suitable for insulation in laboratories. It is a commonly used material for thermal insulation due to its excellent thermal properties. Fiberglass mat tissue has a high resistance to heat transfer, making it an effective insulator to maintain stable temperatures within laboratory spaces. Additionally, fiberglass mat tissue is also resistant to moisture, chemicals, and fire, which are crucial factors in laboratory settings. It can withstand exposure to harsh chemicals and does not degrade or lose its insulating properties over time. This makes it ideal for insulation in laboratories where various chemicals and substances are handled. Furthermore, fiberglass mat tissue is easy to install and can be customized to fit specific insulation requirements. It can be applied to walls, ceilings, and pipes to create a barrier that prevents the transfer of heat, ensuring a controlled environment within the laboratory. Overall, fiberglass mat tissue is a suitable choice for insulation in laboratories due to its thermal resistance, chemical resistance, fire resistance, and ease of installation. It helps to maintain stable temperatures, protects against chemical exposure, and ensures safety in laboratory environments.

- Q: How does fiberglass mat tissue compare to other reinforcing materials, such as carbon fiber or kevlar?

- Fiberglass mat tissue is a reinforcing material that offers several advantages compared to other materials like carbon fiber or Kevlar. While carbon fiber is known for its excellent strength and stiffness, fiberglass mat tissue provides a more cost-effective solution with good strength-to-weight ratio. It is also highly resistant to corrosion, making it suitable for various applications. On the other hand, Kevlar is popular for its exceptional strength and impact resistance, but it is generally more expensive than fiberglass mat tissue. Therefore, the choice between these reinforcing materials depends on the specific requirements of the project, considering factors like cost, strength, stiffness, and corrosion resistance.

- Q: Is fiberglass mat tissue suitable for insulation in residential buildings?

- Yes, fiberglass mat tissue is suitable for insulation in residential buildings. It is a widely used and effective insulation material that offers excellent thermal performance, soundproofing capabilities, and fire resistance. Additionally, it is easy to install, durable, and does not degrade over time.

- Q: Can fiberglass mat tissue be used for composite panel manufacturing?

- Yes, fiberglass mat tissue can be used for composite panel manufacturing. Fiberglass mat tissue is a thin and lightweight material that is typically made from randomly oriented fiberglass strands bonded together with a binder. It is commonly used as a reinforcement material in composite manufacturing processes. When used in composite panel manufacturing, fiberglass mat tissue is typically combined with other materials such as resin and a core material to create a strong and durable panel. The mat tissue provides reinforcement and strength to the panel, helping to distribute loads and prevent cracking or delamination. Fiberglass mat tissue is known for its excellent tensile strength, dimensional stability, and resistance to chemicals, making it well-suited for use in composite panel manufacturing. It can be used in a variety of applications, including construction, transportation, marine, and aerospace industries. Overall, fiberglass mat tissue is a versatile and effective material that can be successfully used in the manufacturing of composite panels. Its properties and characteristics make it a reliable choice for creating strong and durable panels for various applications.

- Q: Can fiberglass mat tissue be used for insulation in hot climates?

- Yes, fiberglass mat tissue can be used for insulation in hot climates. It has excellent thermal insulation properties and can effectively block heat transfer, making it suitable for use in hot climates to maintain cooler indoor temperatures.

- Q: What is the shear strength of fiberglass mat tissue?

- Various factors, including the mat's thickness, the type and quality of the fiberglass material, and the manufacturing process, determine the shear strength of fiberglass mat tissue. Generally, fiberglass mat tissue possesses a higher shear strength compared to other materials. Typically, fiberglass mat tissue consists of multiple layers of glass fibers bonded together with a resin matrix. This combination yields a robust and long-lasting product. The high shear strength of fiberglass mat tissue enables it to withstand significant forces and resist deformation or failure under shear stress. To determine the specific shear strength of a particular fiberglass mat tissue, one must refer to the manufacturer's product specifications. These specifications outline the material's shear strength and other mechanical properties. It is crucial to note that the shear strength of fiberglass mat tissue may vary depending on the specific application and conditions. Factors like temperature, moisture, and exposure to chemicals can affect the material's performance. Therefore, it is advisable to consult the manufacturer's guidelines and seek advice from engineering experts to ensure the appropriate selection and application of fiberglass mat tissue for a given project.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD (0° or 90°) 300/50g

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords