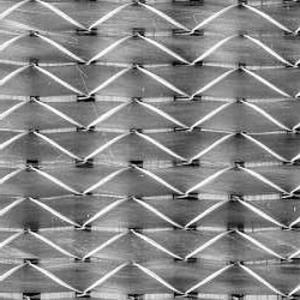

Fiberglass Mat Tissue - Multiaxial Fabric-UD, 950gsm, 0°:750g Chopping:200g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

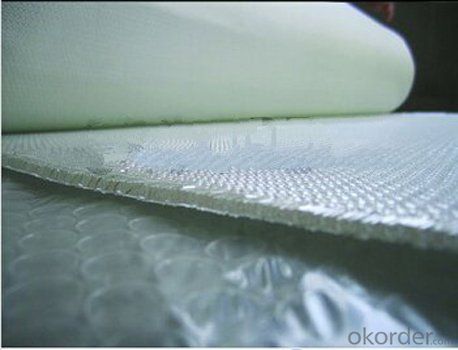

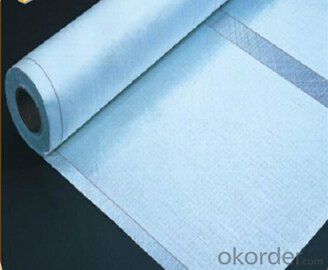

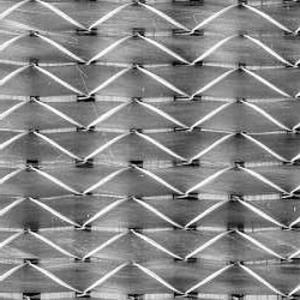

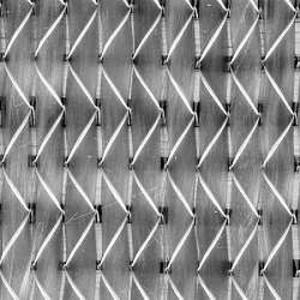

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mainly be used as reinforced materials in the composite material industry: engine room casing, wind deflector, boat, auto frame and pultrusion profiles,etc.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

A:Are you a manufacturer or trading company?

Q:Low price can be offered to you because we are not only a trade company but a manufacturer.We have our factory.

A: How Long have you been in this line for fiberglass?

Q: 10 years working experiences specializing in the production and sale of Fiberglass and other related products.

- Q: Is fiberglass mat tissue chemically resistant?

- Indeed, fiberglass mat tissue possesses chemical resistance. Crafted from finely dispersed glass fibers that are haphazardly arranged and held together with a resin binder, this composition endows the material with superb resistance to an extensive array of chemicals, encompassing acids, alkalis, solvents, and oils. It frequently finds utility in sectors like chemical processing, petrochemicals, and wastewater treatment, where encounters with diverse chemicals are prevalent. The chemical resilience of fiberglass mat tissue renders it a fitting selection for applications that necessitate protection against corrosion and long-lasting sturdiness.

- Q: How does fiberglass mat tissue perform in terms of chemical resistance?

- Fiberglass mat tissue generally exhibits excellent chemical resistance properties. The material is typically made from glass fibers that are held together by a binder, and this composition allows for resistance to a wide range of chemicals. Fiberglass mat tissue is commonly used as a reinforcement in composite materials, such as fiberglass-reinforced plastics (FRP), due to its ability to withstand exposure to various chemicals without degrading or deteriorating. The chemical resistance of fiberglass mat tissue can vary depending on the specific type and quality of the material, as well as the specific chemical being encountered. However, in general, it is highly resistant to most acids, alkalis, solvents, and other corrosive substances. This resistance makes it a suitable choice for applications where the material may come into contact with aggressive chemicals, such as in chemical processing plants, water treatment facilities, or storage tanks. It is important to note that while fiberglass mat tissue is generally chemically resistant, it may not be completely impervious to all chemicals. Some highly concentrated or specialized chemicals may still have the potential to cause damage or deterioration over time. Therefore, it is always advisable to consult the manufacturer's specifications and recommendations for specific chemical resistance information before using fiberglass mat tissue in a particular application. Overall, fiberglass mat tissue is known for its strong chemical resistance properties, making it a reliable choice for applications where exposure to chemicals is expected.

- Q: What is the thermal conductivity of fiberglass mat tissue?

- The thermal conductivity of fiberglass mat tissue is typically low, ranging from 0.03 to 0.06 W/m·K.

- Q: What is the specific gravity of fiberglass mat tissue?

- The specific gravity of fiberglass mat tissue typically ranges between 1.5 and 2.0.

- Q: Is fiberglass mat tissue suitable for automotive panel repairs?

- Yes, fiberglass mat tissue is suitable for automotive panel repairs.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The surface finish of fiberglass mat tissue can significantly affect its adhesion to resin. The surface finish refers to the texture or smoothness of the fiberglass mat tissue. In general, a rougher surface finish tends to provide better adhesion to resin. This is because a rough surface provides more surface area for the resin to adhere to, allowing for a stronger bond. Rougher surface finishes can be achieved through various manufacturing techniques, such as using coarser fibers or adding texturizing agents during production. On the other hand, a smoother surface finish may result in weaker adhesion. A smooth surface does not provide as much surface area for the resin to bond with, leading to a weaker and less durable bond. Smoother surface finishes can be achieved by using finer fibers or through additional processing steps to smooth out the surface. It is important to consider the specific application and requirements when choosing the surface finish of fiberglass mat tissue. For applications that require high strength and durability, a rougher surface finish may be preferred to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a critical role in determining the adhesion to resin. It is essential to select the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: Can fiberglass mat tissue be used in automotive manufacturing?

- Indeed, fiberglass mat tissue finds great utility in the realm of automotive manufacturing. Crafted from interwoven glass fibers bonded by a binder, this pliable and lightweight material serves a multitude of purposes within the automotive industry. It excels at reinforcing body panels, constructing structural components, and improving sound and heat insulation. An advantageous attribute of fiberglass mat tissue in the realm of automotive manufacturing lies in its remarkable strength-to-weight ratio. It bestows superb reinforcement capabilities upon the vehicle while adding minimal mass, rendering it an optimal selection for bolstering fuel efficiency and curbing emissions. Furthermore, fiberglass mat tissue boasts exceptional malleability, enabling effortless shaping and molding into intricate geometries requisite for automotive parts. This material readily reinforces regions susceptible to intense stress, including the roof, doors, and undercarriage, thereby augmenting the vehicle's overall robustness and endurance. Moreover, fiberglass mat tissue exhibits outstanding resistance to corrosion, chemicals, and extreme temperatures, engendering its suitability for deployment in diverse automotive environments. It also serves as an effective insulator against sound and heat, effectively abating noise and preserving a comfortable internal temperature. All in all, fiberglass mat tissue has emerged as a cherished resource in automotive manufacturing, owing to its lightweight, sturdy, moldable, and durable properties. The versatility and performance characteristics it embodies render it the preferred choice for numerous automotive manufacturers seeking to heighten the excellence and performance of their vehicles.

- Q: Is fiberglass mat tissue recyclable?

- Yes, fiberglass mat tissue is recyclable. Fiberglass is made from a combination of glass fibers and a binder material, usually resin. When the material is no longer needed or has reached the end of its life cycle, it can be recycled by separating the glass fibers from the binder material. The glass fibers can then be melted down and used to create new fiberglass products, while the binder material can be treated and reused in other applications. Recycling fiberglass mat tissue helps to reduce waste and conserve natural resources, making it an environmentally friendly option.

- Q: Can fiberglass mat tissue be used for insulation in hot climates?

- Yes, fiberglass mat tissue can be used for insulation in hot climates. It has excellent thermal insulation properties and can effectively block heat transfer, making it suitable for use in hot climates to maintain cooler indoor temperatures.

- Q: Can fiberglass mat tissue be used for repairing fiberglass RVs?

- Yes, fiberglass mat tissue can be used for repairing fiberglass RVs. It is commonly used for reinforcing and repairing fiberglass structures, including RVs, due to its strength and compatibility with fiberglass materials.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD, 950gsm, 0°:750g Chopping:200g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords