Fiberglass Mat Tissue Fiberglass Surfacing Tissue

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 144000 Square Meter m²

- Supply Capability:

- 600000 Square Meter Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

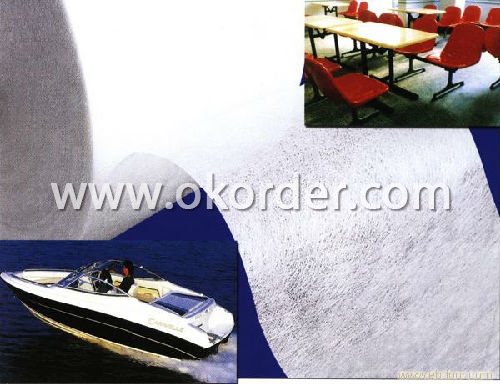

Introduction of Fiberglass surfacing tissue

Fiberglass surfacing tissue is mainly used for the surface layers of FRP products. It has good capability like fiber dispersion, smooth surface, low binder content, fast resin impregnation and good mould obedience. It is capable of significantly improving the strength of FRP surface layer, strong impaction resistance, excellent uniformity of surface, good covering up the texture of under layers and good corrosion resistance.

Specification of Fiberglass surfacing tissue

Size: 20g/, 30g/, 35g/, etc.

Width: 50mm, 75mm, 100mm, 1000mm, etc.

Length: 400m, 500m, 1000m, etc.

Product Characteristics of Fiberglass surfacing tissue

1.Uniform fiber dispersion

2.Smooth surface and soft hand-feeling

3.Low binder content

4.Fast resin impregnation

5.Good mould obedience

6.Good corrosion resistance

7.Strong impact resistance

- Q: Can fiberglass mat tissue be used for insulation in oil refineries?

- Fiberglass mat tissue is unsuitable for insulation in oil refineries due to its inability to withstand the harsh conditions found in such facilities. Its primary purpose lies in the reinforcement of structures in the construction and automotive industries. On the contrary, insulation materials used in oil refineries are carefully selected to ensure fire resistance and chemical resistance. Examples of such materials include mineral wool or calcium silicate, which are engineered to provide optimal thermal insulation and safety in refinery operations.

- Q: What is the maximum temperature fiberglass mat tissue can withstand?

- The maximum temperature that fiberglass mat tissue can withstand depends on various factors such as the specific type of fiberglass used, the thickness of the tissue, and the manufacturing process. Generally, fiberglass mat tissue can withstand temperatures up to 1000°F (538°C) without significant degradation or loss of mechanical properties. However, it is important to note that prolonged exposure to high temperatures can still cause some deterioration in the material's performance. For applications requiring higher temperature resistance, specialized fiberglass materials with enhanced heat resistance can be used. It is recommended to consult the manufacturer or supplier for specific temperature ratings and guidelines for the particular fiberglass mat tissue being used.

- Q: Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a versatile material that is commonly used in various insulation applications due to its excellent thermal insulation properties. It is lightweight, flexible, and provides effective insulation against heat transfer. When used in insulation jackets, fiberglass mat tissue can help to retain heat and prevent heat loss, making it an ideal choice for applications where thermal insulation is required. Additionally, fiberglass mat tissue is also fire-resistant, which further enhances its suitability for insulation jackets.

- Q: Is fiberglass mat tissue suitable for construction applications?

- Indeed, fiberglass mat tissue proves to be a fitting material for construction purposes. Renowned for its robustness, longevity, and ability to withstand diverse environmental conditions, this versatile substance is frequently employed in roofing, flooring, insulation, and wall panel installations. Fiberglass mat tissue emerges as an exceptional selection for construction ventures as it bestows reinforcement and stability upon a range of materials. When incorporated into roofing materials, it fortifies them against impacts, weathering, and fires. Similarly, it bolsters the strength and durability of flooring systems, rendering them capable of withstanding substantial loads and heavy foot traffic. Moreover, fiberglass mat tissue exhibits commendable insulation capabilities. It serves as an efficacious insulating component for walls, ceilings, and floors, enabling the maintenance of a comfortable indoor temperature while diminishing energy consumption. Its thermal and acoustic insulation properties render it an ideal choice for construction applications. Furthermore, its imperviousness to moisture, chemicals, and corrosion makes fiberglass mat tissue a suitable option for deployment in areas characterized by high humidity or exposure to harsh chemicals. Thanks to its resistance to decay, it guarantees durability, ensuring longevity in construction projects. To conclude, fiberglass mat tissue is an apt choice for construction applications due to its strength, durability, insulation properties, and resistance to various environmental factors. Its adaptability and reliability have cemented its popularity within the construction industry.

- Q: Can fiberglass mat tissue be used for making lightweight flooring?

- Yes, fiberglass mat tissue can be used for making lightweight flooring. Fiberglass mat tissue is a material that is commonly used in construction and manufacturing industries for its strength, durability, and lightweight properties. It is made by bonding fine fiberglass strands together with a binder, which results in a thin, flexible, and lightweight material. When used in flooring applications, fiberglass mat tissue can provide several advantages. Firstly, its lightweight nature makes it easier to handle and install, reducing the overall weight of the flooring system. This can be particularly beneficial in applications where weight is a concern, such as in aircraft or mobile homes. Additionally, fiberglass mat tissue is known for its excellent strength-to-weight ratio, making it a suitable material for creating lightweight yet strong flooring. It can provide reinforcement and improve the structural integrity of the flooring, making it more resistant to cracking, warping, or other forms of damage. Furthermore, fiberglass mat tissue is resistant to moisture, chemicals, and fire, making it a suitable choice for areas where these factors are present, such as bathrooms, kitchens, or industrial settings. It also offers good insulation properties, which can help in maintaining a comfortable indoor environment and reducing energy consumption. Overall, fiberglass mat tissue can be an excellent choice for making lightweight flooring due to its strength, durability, moisture resistance, and insulation properties. However, it is important to consider other factors such as the specific requirements of the flooring application, the load-bearing capacity, and the necessary certifications or standards before finalizing the use of fiberglass mat tissue in a flooring project.

- Q: Can fiberglass mat tissue be used for reinforcement in composites?

- Fiberglass mat tissue, composed of glass fibers randomly arranged, can reinforce composites. It is frequently utilized in the manufacturing of composites to enhance their strength. By combining the mat tissue with resin, a sturdy and durable composite material can be created. The random orientation of the fibers contributes to the composite structure's strength and reinforcement in multiple directions. Moreover, the mat tissue's flexibility allows for easy layering and molding into intricate shapes, making it suitable for a range of applications in industries like automotive, aerospace, construction, and marine. In conclusion, fiberglass mat tissue is extensively employed and highly effective as a reinforcement material in composites.

- Q: What is the composition of fiberglass mat tissue?

- Fiberglass mat tissue, also known as fiberglass mat or fiberglass veil, is made up of a combination of fiberglass fibers and a binder material. The fiberglass fibers used in the composition are typically made from silica, a naturally occurring mineral. These fibers are known for their high strength and durability. The binder material used in fiberglass mat tissue can vary, but commonly includes substances like urea-formaldehyde, acrylic, or polyester resins. The role of the binder is to hold the fiberglass fibers together and provide structural integrity to the mat. In addition to the fiberglass fibers and binder, other additives may be included in the composition of fiberglass mat tissue. These additives can include substances such as pigments, fire retardants, or coatings, depending on the specific application and desired properties of the mat. Overall, the composition of fiberglass mat tissue is a combination of fiberglass fibers and a binder material, with additional additives depending on the intended use. This composition allows fiberglass mat tissue to possess excellent strength, flexibility, and resistance to various environmental factors, making it a versatile material used in various industries such as construction, automotive, aerospace, and marine.

- Q: How is fiberglass mat tissue bonded to surfaces?

- Fiberglass mat tissue is typically bonded to surfaces using a combination of adhesive and pressure. The adhesive, commonly a resin or epoxy, is applied to the surface and then the fiberglass mat tissue is pressed onto it. This ensures proper adhesion and allows the mat tissue to conform to the surface contours. Once bonded, the adhesive is cured to permanently bond the fiberglass mat tissue to the surface.

- Q: How does fiberglass mat tissue compare to fiberglass mesh?

- Fiberglass mat tissue and fiberglass mesh serve different purposes and exhibit distinct characteristics. Fiberglass mat tissue, a lightweight and flexible material, finds common use in the production of fiberglass-reinforced plastics (FRP). It is created by randomly dispersing glass fibers onto a mesh or non-woven fabric, which is then bonded with resin. This yields a material with a smooth surface and higher tensile strength compared to fiberglass mesh. Its exceptional strength and stiffness make it an ideal choice for applications that necessitate structural reinforcement, such as automotive parts, boat hulls, and wind turbine blades. Conversely, fiberglass mesh is a woven fabric composed of continuous glass fibers. With its open mesh structure, it facilitates better resin penetration and adhesion. Fiberglass mesh is frequently employed to reinforce surfaces like concrete, stucco, and drywall. It offers excellent crack resistance, dimensional stability, and impact resistance. In construction and renovation projects, fiberglass mesh proves particularly valuable as it reinforces surfaces and prevents cracking. In conclusion, fiberglass mat tissue is better suited for applications requiring structural reinforcement and strength, like FRP production. Its smooth surface and high tensile strength set it apart. On the other hand, fiberglass mesh is commonly used in construction projects to reinforce surfaces and prevent cracking. Its open mesh structure allows for improved resin penetration and adhesion. Ultimately, the choice between fiberglass mat tissue and fiberglass mesh depends on the specific requirements of the application at hand.

- Q: Can fiberglass mat tissue be used for reinforcing concrete?

- Indeed, reinforcing concrete is possible with the utilization of fiberglass mat tissue. This lightweight and flexible material is frequently employed in construction endeavors to augment the sturdiness and endurance of concrete structures. By embedding it within the concrete, additional reinforcement is provided, which aids in averting the formation of cracks over time. Typically crafted from top-notch glass fibers that are interwoven to form a robust and steady substance, fiberglass mat tissue showcases exceptional tensile strength and corrosion resistance, rendering it an optimal selection for enhancing the performance of concrete. Whether employed in sidewalks, driveways, or other concrete formations, the presence of fiberglass mat tissue can substantially heighten the potency and lifespan of the concrete in question.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2008 |

| Annual Output Value | Above US$20 Million |

| Main Markets | Mid East;Western Europe:South Asian |

| Company Certifications | ISO9001:2000;ISO14001:1996;GB/T28001:2001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 350 People |

| Language Spoken: | English;Chinese;Korean |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fiberglass Mat Tissue Fiberglass Surfacing Tissue

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 144000 Square Meter m²

- Supply Capability:

- 600000 Square Meter Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords