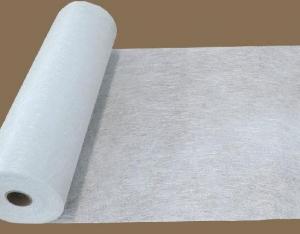

Fiberglass Mat Tissue 'е-стекломат московский пятно, хорошее качество'

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 21000kg kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Стекломат эмульсионный

Эмульсионный стекломат производится из Е-стекло ровинга,клиееного эмульсионным вяжущим,обладает хорошей способностью смачивания с полиэфирным,виниловым и эпоксидным смолам.

Продукты из данного стекломата преимущественно перерабатываются методами ручного формования,намотки и прессования, широко применяются для производства разных стеклопластиков,корпусов лодок,автомобильных запчастей и охлаждающих башен.

Мы поставляем стекломат 300г\450г\600г по ширине 1250мм !!!

Основные преимущества

1.Вследствие хорошей целостности достигает более высокого стеклосодержания и коэффициента армирования,чтобы повышает механической прочности стекпластика

2.Данный стекломат отличается хорошей целостностью и формуемкостью,малым выделением летучних веществ в процессе переработки;

3.Отличная гибность подходит к формованию

4.Быстрая и полная смачиваемость в смоле,малая потребность смолы преведут к снижению себестоимости производства,повышению производительности и механических свойств конечных продуктов.

Упаковка:

Стекломат намотан на бумажные патроны.Рулоны заворачиваются пластмассовыми плеками,уложены в бумажные коробки,или заворавиваются крафт-бумагой.Рулон должны положить горизонтально.В транспортировке рулоны могут прямо загружать в котейнеры или с помошью поддонов.

Добро пожаловать посетить наш склад !

- Q: How does fiberglass mat tissue perform in terms of air permeability?

- Fiberglass mat tissue is characterized by its low air permeability. Its tight weave and construction, using fiberglass strands, result in less porosity, thereby allowing minimal airflow. This quality renders fiberglass mat tissue appropriate for situations that require minimal air permeability, such as insulation or filtration systems. By limiting the flow of air, fiberglass mat tissue enhances thermal insulation and enhances filtration efficiency.

- Q: What is the typical width of fiberglass mat tissue rolls?

- The typical width of fiberglass mat tissue rolls can vary depending on the specific manufacturer and intended application. However, in the construction and insulation industries, fiberglass mat tissue rolls are commonly available in widths ranging from 1.22 meters (4 feet) to 2.44 meters (8 feet). These dimensions are often chosen to align with standard building materials and construction practices. It is important to note that there may be variations in width options depending on the region or supplier, so it is advisable to consult with the manufacturer or supplier for the specific width requirements for a particular project.

- Q: What is the moisture resistance of fiberglass mat tissue?

- Fiberglass mat tissue boasts a generally high level of moisture resistance. It is typically crafted from tightly woven fiberglass strands, resulting in a dense and water-resistant surface. This characteristic renders it exceptionally effective in situations where moisture exposure is prevalent, particularly in the construction field for roofing, insulation, and waterproofing applications. Furthermore, manufacturers frequently apply special coatings or additives to enhance its moisture resistance, thereby increasing its durability and reliability in wet or humid environments. As a result of this advantageous feature, fiberglass mat tissue finds extensive utilization across numerous industries.

- Q: Is fiberglass mat tissue suitable for insulation in high-rise buildings?

- High-rise buildings can benefit from the suitability of fiberglass mat tissue for insulation. This widely used material possesses exceptional thermal and acoustic properties, making it an ideal choice. Its lightweight and flexible nature, along with easy installation, ensure efficiency and effectiveness in high-rise structures. Furthermore, fiberglass mat tissue boasts excellent fire resistance, a crucial requirement for multi-story buildings. It also resists moisture, mold, and pests, ensuring durability and optimal performance. Customization for walls, floors, and ceilings allows consistent insulation throughout the entire building. In conclusion, fiberglass mat tissue is a dependable and cost-effective insulation solution for high-rise buildings.

- Q: How does fiberglass mat tissue perform in terms of heat insulation?

- Fiberglass mat tissue performs relatively well in terms of heat insulation. Due to its composition of fine glass fibers and a binder, it has good thermal resistance properties. These fibers trap air pockets, which act as thermal barriers by reducing heat transfer. This makes fiberglass mat tissue a suitable insulation material for various applications, such as in the construction industry for insulating walls, roofs, and attics. Additionally, fiberglass mat tissue is also commonly used in automotive and aerospace industries to insulate engine compartments and reduce heat transfer through vehicle panels, respectively. However, it is important to note that while fiberglass mat tissue provides excellent thermal insulation, it may not be as effective as some other insulation materials, such as foam or mineral wool, which have higher thermal resistance values. Overall, fiberglass mat tissue is a reliable option for heat insulation, but the specific requirements of the project should be considered to determine the most suitable insulation material.

- Q: What is the expected lifespan of fiberglass mat tissue in underground applications?

- The expected lifespan of fiberglass mat tissue in underground applications can vary depending on various factors such as the specific conditions, environmental factors, and maintenance practices. However, on average, fiberglass mat tissue used in underground applications can have a lifespan ranging from 25 to 50 years.

- Q: Can fiberglass mat tissue be used for automotive parts?

- Automotive parts can indeed utilize fiberglass mat tissue. This adaptable material offers strength, rigidity, and durability. Within the automotive industry, it finds widespread use in a range of applications including reinforcing panels, bumpers, hoods, and body parts. Its lightweight composition makes it ideal for reducing vehicle weight and enhancing fuel efficiency. Moreover, it boasts resistance against corrosion, chemicals, and extreme temperatures, rendering it a dependable choice for automotive parts. Its flexibility further enables manufacturers to easily mold and shape it, facilitating the creation of intricate designs and desired aesthetics. Considering its strength, durability, lightweight nature, and versatility, fiberglass mat tissue stands as an exceptional option for automotive parts.

- Q: What is the moisture absorption rate of fiberglass mat tissue?

- The moisture absorption rate of fiberglass mat tissue is relatively low, as fiberglass is known for its water-resistant properties.

- Q: Can fiberglass mat tissue be used in automotive manufacturing?

- Yes, fiberglass mat tissue can be used in automotive manufacturing. Fiberglass mat tissue is a lightweight, flexible material made from glass fibers that are bonded together with a binder. It is commonly used in the automotive industry for various applications such as reinforcing body panels, creating structural components, and improving sound and heat insulation. One of the main advantages of using fiberglass mat tissue in automotive manufacturing is its high strength-to-weight ratio. It provides excellent reinforcement properties while adding minimal weight to the vehicle, making it an ideal choice for achieving fuel efficiency and reducing emissions. Additionally, fiberglass mat tissue is highly moldable, allowing it to be easily shaped and formed into complex geometries required for automotive parts. This material can be used to reinforce areas that are susceptible to high stress, such as the roof, doors, and undercarriage, thereby enhancing the overall strength and durability of the vehicle. Moreover, fiberglass mat tissue offers excellent resistance to corrosion, chemicals, and extreme temperatures, making it suitable for use in diverse automotive environments. It is also an effective sound and heat insulator, helping to reduce noise and maintain a comfortable interior temperature. Overall, fiberglass mat tissue has proven to be a valuable material in automotive manufacturing due to its lightweight, strong, moldable, and durable properties. Its versatility and performance characteristics make it a preferred choice for many automotive manufacturers looking to enhance the quality and performance of their vehicles.

- Q: Does fiberglass mat tissue require any surface preparation before application?

- Yes, fiberglass mat tissue usually requires surface preparation before application. This may include cleaning the surface, removing any loose particles, and ensuring it is dry and free from any contaminants. Proper surface preparation helps to ensure good adhesion and a successful application of fiberglass mat tissue.

Send your message to us

Fiberglass Mat Tissue 'е-стекломат московский пятно, хорошее качество'

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 21000kg kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords