Fiberglass Mat Tissue - Multiaxial Fabric-UD, 1050gsm (90°:600g, Chopping:450g)

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Fiberglass Multiaxial Fabric-UD Description:

An engineering material, which has many excellent characterstics, such as anti-burning, corrosion resistent, stable structure, heat-isolating, minimum elongated shrinkage, high intensity, etc. This new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc. According to fabric organizational structure and appearance, there are such kind of products: plain weave, twill weave, satin weave, gauze weave.

Main Features of the Fiberglass Multiaxial Fabric-UD:

1)Plain veave,even thickness and low fuzz;

2)High strength in both warp and weft direction;

3)Incombustibility,corrosion resistance and heat resistance;

4)E-Grade Fabric (E-fiberglass Textile Cloth) has excellent electricity insulation property.

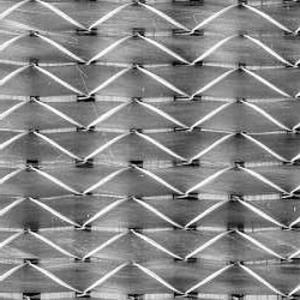

Fiberglass Multiaxial Fabric-UD Images:

Unidirectional Specification:

Code | Total weight g/m2 | Weight of each layer, g/m2 | Width mm | ||||

0° | 90° | +45° | -45° | Chopping | |||

E-L300 | 350 | 300 | 50 | 200~2600 | |||

E-L350 | 400 | 350 | 50 | 200~2600 | |||

E-L400 | 450 | 400 | 50 | 200~2600 | |||

E-L450 | 500 | 450 | 50 | 200~2600 | |||

E-L500 | 550 | 500 | 50 | 200~2600 | |||

E-L600 | 650 | 600 | 50 | 200~2600 | |||

E-L650 | 700 | 650 | 50 | 200~2600 | |||

E-L900 | 930 | 880 | 50 | 200~2600 | |||

E-L700/200 | 950 | 700 | 50 | 200 | 200~2600 | ||

E-T200 | 200 | 200 | 200~2600 | ||||

E-T450 | 450 | 450 | 200~2600 | ||||

E-T500 | 500 | 500 | 200~2600 | ||||

E-TM300/300 | 600 | 300 | 300 | 200~2600 | |||

E-TM600/450 | 1050 | 600 | 450 | 200~2600 | |||

E-LM750/200 | 950 | 750 | 200 | 200~2600 | |||

FAQ of Chopped strand mat

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: How long does fiberglass mat tissue last?

- The durability and longevity of fiberglass mat tissue can change depending on different factors, including its quality, usage, and exposure to external conditions. Typically, fiberglass mat tissue is designed to be highly durable and long-lasting. When installed and maintained correctly, it can endure for many decades. However, it is worth noting that fiberglass mat tissue can degrade over time due to environmental elements like UV exposure, moisture, and temperature fluctuations. Continuous exposure to harsh weather conditions, extreme temperatures, or chemicals can speed up the deterioration process. To maximize the lifespan of fiberglass mat tissue, it is vital to adhere to the manufacturer's guidelines for installation, maintenance, and regular inspections. Regular inspections can help detect any signs of wear, damage, or degradation early on, enabling timely repairs or replacements. For specific information regarding the expected lifespan of a particular fiberglass mat tissue and its intended application, it is advisable to seek advice from a professional or directly consult the manufacturer. The expected lifespan can vary depending on the specific product and its intended use.

- Q: Can fiberglass mat tissue be used for reinforcing fiberglass boats?

- Yes, fiberglass mat tissue can be used for reinforcing fiberglass boats. Fiberglass mat tissue is a non-woven material made up of randomly oriented fiberglass strands held together by a binder. It is lightweight, flexible, and easy to work with, making it an ideal choice for reinforcing fiberglass boats. When used in boat construction, fiberglass mat tissue is typically used in conjunction with fiberglass resin to create a strong and durable composite material. The mat tissue is laid down and impregnated with resin, which then cures and hardens to form a rigid structure. This process helps to increase the strength, stiffness, and impact resistance of the boat. Fiberglass mat tissue is commonly used in areas that require additional reinforcement, such as the hull, deck, or other high-stress areas. It helps to distribute and absorb forces, reducing the risk of cracking or failure. Additionally, it can provide added protection against impacts and abrasions, helping to prolong the lifespan of the boat. However, it is important to note that fiberglass mat tissue alone may not be sufficient for reinforcing fiberglass boats. It is often used in combination with other reinforcement materials, such as fiberglass cloth or woven roving, to provide a balanced and optimized reinforcement system. Ultimately, the use of fiberglass mat tissue for reinforcing fiberglass boats can greatly enhance their structural integrity and durability. It is a versatile and cost-effective option that is widely used in the boat building industry.

- Q: What is the thermal conductivity of fiberglass mat tissue?

- The thermal conductivity of fiberglass mat tissue is typically low, ranging from 0.03 to 0.05 W/m·K. This means that fiberglass mat tissue is a good insulator and can effectively resist the transfer of heat. Its low thermal conductivity makes it suitable for applications such as thermal insulation in buildings, industrial equipment, and appliances.

- Q: What are the different types of fiberglass mat tissue available?

- A variety of fiberglass mat tissues can be found, each possessing its own distinct qualities and uses. Some commonly encountered types include the following: 1. Chopped Strand Mat (CSM): This is the most widely utilized and fundamental kind of fiberglass mat tissue. It comprises randomly arranged chopped fiberglass strands held together by a binder. CSM is commonly employed in situations where strength and resilience are crucial, such as in the construction of boats and automotive components. 2. Continuous Filament Mat (CFM): Unlike CSM, CFM is fashioned from continuous fiberglass strands woven into a mat. This type of fiberglass mat tissue offers exceptional tensile strength and dimensional stability, making it ideal for applications necessitating high strength and stiffness, such as in aerospace components and wind turbine blades. 3. Surface Veil Mat: Surface veil mat is an extremely thin and lightweight fiberglass mat tissue primarily used for surface finishing and reinforcement. It is typically applied as a final layer in composite laminates to enhance surface smoothness and water resistance. 4. Stitched Mat: Stitched mat is produced by interweaving continuous fiberglass strands with stitching thread. This construction yields enhanced strength and improved drapability, facilitating easier conformity to complex shapes. Stitched mat is commonly utilized in applications necessitating a blend of strength and flexibility, such as in the production of pipes and tanks. 5. Binderless Mat: Binderless mat is a specialized kind of fiberglass mat tissue that lacks binders or resins. Instead, the fibers are mechanically bonded through a needling process. This renders binderless mat highly resistant to chemical attack and suitable for use in corrosive environments, such as chemical storage tanks and pipes. These examples merely touch upon the wide range of fiberglass mat tissues available. The selection of which type to employ hinges on the specific requirements of the application, encompassing factors such as strength, flexibility, surface finish, and resistance to various environmental influences.

- Q: How does fiberglass mat tissue perform in terms of thermal expansion?

- Fiberglass mat tissue generally has a low coefficient of thermal expansion, which means it expands and contracts minimally with changes in temperature. This makes it a suitable material for applications where thermal stability is important.

- Q: What is the tensile strength of fiberglass mat tissue?

- The tensile strength of fiberglass mat tissue typically ranges between 30 and 150 pounds per inch (lb/in). However, it is important to note that the exact tensile strength can vary depending on the specific type and quality of fiberglass mat tissue being used.

- Q: What are the different surface textures available for fiberglass mat tissue?

- Some of the different surface textures available for fiberglass mat tissue include smooth, coarse, textured, embossed, and patterned.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Yes, fiberglass mat tissue is suitable for soundproofing. It is an effective material for absorbing and dampening sound waves, making it a popular choice for soundproofing applications in buildings, vehicles, and other structures.

- Q: Can fiberglass mat tissue be used for insulation in research laboratories?

- Indeed, insulation in research laboratories can utilize fiberglass mat tissue. This material, widely employed for thermal and acoustic insulation, boasts exceptional insulating qualities. Its resistance to heat, moisture, and chemicals renders it ideal for laboratory environments. Moreover, fiberglass mat tissue's lightweight nature and effortless installation enable swift and efficient insulation in research laboratories. Its low thermal conductivity further aids in maintaining stable temperature conditions, guaranteeing optimal experiment conditions while curbing energy consumption. In conclusion, fiberglass mat tissue presents itself as a practical option for insulating research laboratories.

- Q: Can fiberglass mat tissue be used for insulation?

- Yes, fiberglass mat tissue can be used for insulation. It is commonly used in the construction industry as a thermal and sound insulation material. The fiberglass mat tissue is made up of fine fibers of glass that are woven into a mat-like structure. This structure traps air and creates a barrier that helps to reduce heat transfer, keeping the desired area insulated and maintaining a comfortable temperature. Additionally, fiberglass mat tissue is also resistant to moisture, fire, and pests, making it a suitable choice for insulation in various applications.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD, 1050gsm (90°:600g, Chopping:450g)

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords