Fiberglass Mat Tissue Unidirectional Fabric 1000gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

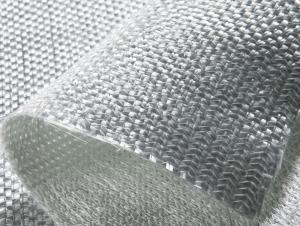

Structure of unidirectional fiberglass fabric Description:

An engineering material, which has many excellent characterstics, such as anti-burning, corrosion resistent, stable structure, heat-isolating, minimum elongated shrinkage, high intensity, etc. This new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc. According to fabric organizational structure and appearance, there are such kind of products: plain weave, twill weave, satin weave, gauze weave.

Main Features of the unidirectional fiberglass fabric:

1)Plain veave,even thickness and low fuzz;

2)High strength in both warp and weft direction;

3)Incombustibility,corrosion resistance and heat resistance;

4)E-Grade Fabric (E-fiberglass Textile Cloth) has excellent electricity insulation property.

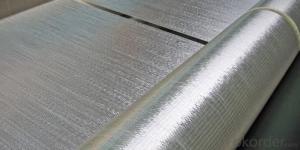

Unidirectional fiberglass fabric Images:

Unidirectional Specification:

specifications | Fibre type | 0°Roving | 90°Roving | Overall weight | Width |

(g/㎡) | (g/㎡) | (g/㎡) | (mm) | ||

EDW227 | E-Glass | — | 227 | 227 | 1524 |

EDW350 | E-Glass | — | 350 | 350 | 1524 |

EDW450 | E-Glass | — | 450 | 450 | 1524 |

EDJ600 | E-Glass | 480 | 120 | 600 | 1524 |

EDJ800 | E-Glass | 600 | 200 | 800 | 1524 |

EDJ1000 | E-Glass | 600 | 400 | 1000 | 1524 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||||

FAQ of woven roving:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can fiberglass mat tissue be used for architectural facades?

- Yes, fiberglass mat tissue can be used for architectural facades. It is a versatile material that offers excellent strength, durability, and weather resistance, making it suitable for various applications including architectural facades.

- Q: How does fiberglass mat tissue perform in terms of acoustic insulation?

- Fiberglass mat tissue performs exceptionally well in terms of acoustic insulation. Due to its unique composition of fine fibers, it effectively absorbs sound waves and reduces airborne noise transmission. The mat tissue's dense structure enhances its soundproofing abilities, making it an ideal choice for applications where noise control is critical. Additionally, fiberglass mat tissue has superior thermal insulation properties, which further contributes to its acoustic insulation performance. Overall, this material is highly effective in minimizing sound transmission and creating quieter and more peaceful environments.

- Q: Does fiberglass mat tissue provide good acoustical performance?

- Fiberglass mat tissue does provide good acoustical performance. Due to its composition, which includes fine glass fibers, this material is effective in absorbing sound waves and reducing echo and reverberation in a space. Fiberglass mat tissue has excellent sound absorption properties, making it suitable for applications in various industries such as construction, automotive, and aerospace. Its ability to dampen sound and improve acoustics makes it a popular choice for soundproofing walls, ceilings, and floors in buildings. Additionally, fiberglass mat tissue is lightweight and easy to install, further enhancing its appeal for acoustical applications.

- Q: Is fiberglass mat tissue suitable for insulation in educational facilities?

- Yes, fiberglass mat tissue is suitable for insulation in educational facilities. It offers excellent thermal insulation properties, is easy to install, and provides effective soundproofing. Additionally, it is fire-resistant, durable, and cost-effective, making it a practical choice for educational buildings.

- Q: What are the different types of resins compatible with fiberglass mat tissue?

- There are several types of resins that are compatible with fiberglass mat tissue, including polyester resin, epoxy resin, and vinyl ester resin. These resins provide different properties and characteristics to the fiberglass mat, such as strength, durability, and resistance to chemicals or UV degradation. The choice of resin depends on the specific application and desired performance of the fiberglass product.

- Q: How does fiberglass mat tissue compare to polystyrene insulation?

- Fiberglass mat tissue and polystyrene insulation are two different materials used for insulation purposes, and they have their own distinct characteristics and benefits. Fiberglass mat tissue is made from thin strands of glass fibers that are woven together to form a mat. It is commonly used in applications where heat and sound insulation is required. Fiberglass mat tissue is known for its excellent thermal insulation properties, as it can effectively resist heat transfer, making it suitable for both hot and cold environments. Additionally, it is resistant to moisture and does not promote the growth of mold or mildew. On the other hand, polystyrene insulation is a foam material made from expanded polystyrene beads. It is widely used in the construction industry as it provides good thermal insulation and can be easily shaped or cut to fit various spaces. Polystyrene insulation is known for its high compressive strength, making it ideal for load-bearing applications. It is also moisture-resistant, lightweight, and has excellent resistance to aging and degradation. When comparing fiberglass mat tissue to polystyrene insulation, there are a few key differences to consider. Fiberglass mat tissue is generally more flexible and can be easier to install in irregular or curved surfaces. It is also more resistant to fire, as it does not burn or release toxic gases when exposed to flames. However, fiberglass mat tissue can be more expensive than polystyrene insulation and may require additional protective measures, such as wearing gloves and masks during installation, due to its potential for skin and respiratory irritation. Polystyrene insulation, on the other hand, is less expensive and easier to handle and install compared to fiberglass mat tissue. It also has better moisture resistance, which makes it suitable for applications in areas with high humidity or potential water exposure. However, polystyrene insulation is more flammable than fiberglass mat tissue and can release toxic gases when burned. In conclusion, the choice between fiberglass mat tissue and polystyrene insulation depends on the specific requirements of the insulation project. Fiberglass mat tissue is well-suited for its excellent thermal insulation properties, fire resistance, and resistance to moisture and mold. Polystyrene insulation, on the other hand, offers good thermal insulation, ease of installation, and high compressive strength. Ultimately, it is important to consider factors such as cost, installation requirements, fire resistance, and moisture resistance when deciding between fiberglass mat tissue and polystyrene insulation.

- Q: Can fiberglass mat tissue be used for insulating exterior walls?

- Insulating exterior walls can be done using fiberglass mat tissue. This particular type of insulation material is commonly chosen for its exceptional thermal and acoustic insulation properties. It is composed of fine glass fibers that are bonded together with a binder, resulting in a lightweight and flexible material. When applied to insulate exterior walls, fiberglass mat tissue is typically installed either between the wall studs or in the wall cavities. By trapping air within its fibers, it effectively reduces heat transfer and acts as a barrier against heat loss or gain. This insulation material plays a significant role in enhancing a building's energy efficiency by reducing the need for heating or cooling, thus leading to lower energy costs and carbon emissions. In addition to its insulating properties, fiberglass mat tissue is also resistant to moisture, mold, and mildew, which makes it suitable for external applications. It contributes to creating a more comfortable and healthier indoor environment by preventing the growth of harmful microorganisms and minimizing condensation. Furthermore, it provides an extra layer of safety to the building as it is fire-resistant. To summarize, fiberglass mat tissue is a versatile and efficient insulation material that can be utilized for insulating exterior walls. Its exceptional thermal and acoustic properties, resistance to moisture and fire, make it an excellent choice for improving the energy efficiency and comfort of buildings.

- Q: Can fiberglass mat tissue be used for electrical enclosures?

- No, fiberglass mat tissue is not suitable for electrical enclosures as it does not provide sufficient insulation properties necessary for electrical safety.

- Q: How does fiberglass mat tissue enhance the strength of composite materials?

- The enhancement of composite material strength is greatly influenced by fiberglass mat tissue. Made up of thin fiberglass strands woven together, the tissue possesses a distinctive structure, with the strands randomly oriented and bonded by a resin binder. This unique structure offers several advantages to composite materials. Firstly, the random orientation of the fiberglass strands within the tissue aids in the even distribution of stress and load across the composite material. Consequently, when a force is exerted on the composite, the tissue prevents localized stress concentrations that could result in cracks or failure. By distributing stress, the fiberglass mat tissue enhances the overall strength and durability of the composite material. Secondly, the resin binder utilized in the fiberglass mat tissue serves as both a reinforcement and bonding agent. During the manufacturing process of the composite material, the resin binder infiltrates the fibers of the tissue, creating a robust and cohesive structure. This not only enhances the overall strength of the composite material but also improves its resistance to impact and fatigue. Moreover, the presence of fiberglass strands within the tissue augments the stiffness of the composite material. When combined with the resin binder, these strands establish a rigid framework that enhances the structural integrity of the composite. This increased stiffness renders the material more resistant to deformation and improves its load-bearing capabilities. Additionally, fiberglass mat tissue offers thermal and electrical insulation properties to composite materials. The fiberglass strands act as a barrier, minimizing heat transfer and preventing electrical conductivity. Consequently, the composite material becomes suitable for applications that require insulation, such as in electrical enclosures or thermal insulation panels. In conclusion, fiberglass mat tissue plays a critical role in enhancing the strength of composite materials by distributing stress, reinforcing the structure, increasing stiffness, and providing additional insulation properties. With its random orientation, resin binder, and unique characteristics, it is an indispensable component in the production of high-performance composites utilized across various industries, including aerospace, automotive, construction, and marine.

- Q: What is the weight of fiberglass mat tissue per square meter?

- The weight of fiberglass mat tissue per square meter can vary depending on the specific product and manufacturer. However, on average, fiberglass mat tissue typically weighs around 100-300 grams per square meter.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 1000gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords