Fiberglass Mat Tissue Unidirectional Fabric 800gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

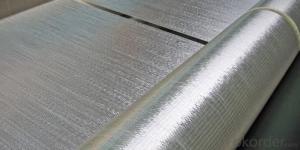

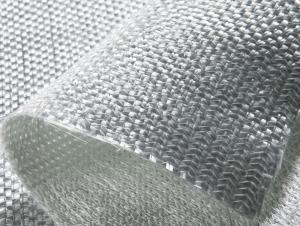

Structure of unidirectional fiberglass fabric Description:

An engineering material, which has many excellent characterstics, such as anti-burning, corrosion resistent, stable structure, heat-isolating, minimum elongated shrinkage, high intensity, etc. This new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc. According to fabric organizational structure and appearance, there are such kind of products: plain weave, twill weave, satin weave, gauze weave.

Main Features of the unidirectional fiberglass fabric:

1)Plain veave,even thickness and low fuzz;

2)High strength in both warp and weft direction;

3)Incombustibility,corrosion resistance and heat resistance;

4)E-Grade Fabric (E-fiberglass Textile Cloth) has excellent electricity insulation property.

Unidirectional fiberglass fabric Images:

Unidirectional Specification:

Code | Total weight g/m2 | Weight of each layer, g/m2 | Width mm | ||||

0° | 90° | +45° | -45° | Chopping | |||

E-L300 | 350 | 300 | 50 | 200~2600 | |||

E-L350 | 400 | 350 | 50 | 200~2600 | |||

E-L400 | 450 | 400 | 50 | 200~2600 | |||

E-L450 | 500 | 450 | 50 | 200~2600 | |||

E-L500 | 550 | 500 | 50 | 200~2600 | |||

E-L600 | 650 | 600 | 50 | 200~2600 | |||

E-L650 | 700 | 650 | 50 | 200~2600 | |||

E-L900 | 930 | 880 | 50 | 200~2600 | |||

E-L700/200 | 950 | 700 | 50 | 200 | 200~2600 | ||

E-T200 | 200 | 200 | 200~2600 | ||||

E-T450 | 450 | 450 | 200~2600 | ||||

E-T500 | 500 | 500 | 200~2600 | ||||

E-TM300/300 | 600 | 300 | 300 | 200~2600 | |||

E-TM600/450 | 1050 | 600 | 450 | 200~2600 | |||

E-LM750/200 | 950 | 750 | 200 | 200~2600 | |||

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Can fiberglass mat tissue be used for repairing fiberglass structures?

- Fiberglass structures can be repaired using fiberglass mat tissue. This material is widely used in the construction and repair of fiberglass structures because of its versatility. Its purpose is to strengthen and reinforce damaged areas of the structure. To ensure a durable repair, the mat tissue is usually applied with resin, which bonds the fibers together. It is particularly effective for fixing cracks, holes, and other damages on fiberglass surfaces. In summary, fiberglass mat tissue is an outstanding option for repairing fiberglass structures due to its strength, flexibility, and ability to adapt to different shapes and sizes.

- Q: Can fiberglass mat tissue be used for flooring insulation?

- Typically, fiberglass mat tissue is not employed for flooring insulation. It is a lightweight substance frequently utilized in the construction sector to reinforce plaster and concrete, and as insulation in walls and ceilings. However, for flooring insulation purposes, other materials like foam boards or batt insulation are generally favored. These materials offer superior thermal and sound insulation features that are specifically tailored for flooring applications. Moreover, they are simpler to install and better equipped to endure the pressures and demands of foot traffic on the flooring.

- Q: What are the potential limitations of using fiberglass mat tissue?

- There are several potential limitations of using fiberglass mat tissue. Firstly, fiberglass mat tissue is relatively brittle compared to other materials. This means that it may be prone to cracking or breaking under certain conditions, especially if it is subjected to high levels of stress or impact. This can limit its use in applications where durability and flexibility are important. Secondly, fiberglass mat tissue is not inherently resistant to moisture. If exposed to water or high humidity for extended periods of time, it may absorb moisture and lose its structural integrity. This can make it unsuitable for use in environments where moisture resistance is a critical requirement. Additionally, fiberglass mat tissue can be challenging to work with due to its sharp edges and fibers. Special precautions, such as wearing protective clothing and using proper handling techniques, are necessary to avoid injury. This can increase the complexity and cost of using fiberglass mat tissue in certain applications. Furthermore, fiberglass mat tissue may release fine particles or fibers into the air when cut or manipulated. These particles can pose health risks if inhaled, potentially leading to respiratory issues or irritation. Proper safety measures, such as using masks and adequate ventilation, must be taken to minimize these risks. Lastly, fiberglass mat tissue is a relatively expensive material compared to some alternatives. Its production process involves multiple steps and specialized equipment, which can contribute to higher costs. This can limit its use in applications where cost-effectiveness is a primary consideration. Overall, while fiberglass mat tissue offers various advantages in terms of strength, insulation, and fire resistance, its potential limitations should be carefully considered before selecting it for a specific application.

- Q: Can fiberglass mat tissue be used for bridge construction?

- Yes, fiberglass mat tissue can be used for bridge construction. Fiberglass mat tissue is a versatile material that offers several advantages. It is lightweight yet strong, making it suitable for use in bridge construction where weight considerations are important. Additionally, fiberglass mat tissue is highly durable and resistant to corrosion, which is crucial for the longevity and maintenance of bridges. It can also be easily molded into various shapes, allowing for flexibility in bridge design. Moreover, fiberglass mat tissue has good impact resistance and excellent fatigue performance, ensuring the bridge's ability to withstand heavy loads and constant traffic. Overall, fiberglass mat tissue is a reliable and cost-effective material for bridge construction.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- Pharmaceutical storage areas can benefit from the use of fiberglass mat tissue for insulation purposes. This versatile material possesses outstanding thermal insulation properties and is widely used in various industries, including pharmaceuticals. Its ability to regulate temperature and provide insulation against heat transfer makes it an excellent choice for these storage areas. In order to preserve the quality and stability of medications and vaccines, maintaining the appropriate temperature is crucial. By reducing heat transfer between different areas and safeguarding the stored products from external temperature fluctuations, fiberglass mat tissue helps create a temperature-controlled environment. Furthermore, fiberglass mat tissue is lightweight, easy to install, and resistant to moisture, making it highly suitable for pharmaceutical storage areas that require cleanliness and hygiene. It can be effortlessly positioned between walls, ceilings, and floors, acting as a barrier against heat flow and effectively maintaining the desired temperature within the storage area. Moreover, fiberglass mat tissue is a non-combustible material, adding an extra layer of safety in pharmaceutical storage areas. It does not contribute to the spread of fire, thus ensuring the protection of valuable pharmaceutical products and minimizing the risk of fire-related accidents. In conclusion, fiberglass mat tissue is a reliable choice for insulation in pharmaceutical storage areas. It offers thermal regulation, moisture resistance, cleanliness, and fire safety, ultimately contributing to the maintenance of the necessary temperature and the preservation of the integrity and stability of stored medications and vaccines.

- Q: How does fiberglass mat tissue perform in terms of mold and mildew resistance?

- Fiberglass mat tissue possesses exceptional mold and mildew resistance. Its inherent moisture resistance prevents the proliferation of mold and mildew. Moreover, fiberglass is impermeable and unsuitable for the flourishing of these microorganisms. Furthermore, fiberglass mat tissue finds extensive usage in areas with high humidity, like bathroom walls or showers, and has proven highly efficient in deterring mold and mildew growth. All in all, fiberglass mat tissue exhibits outstanding performance in terms of mold and mildew resistance, rendering it a dependable option for situations where these issues are prominent.

- Q: How does fiberglass mat tissue compare to polystyrene insulation?

- Fiberglass mat tissue and polystyrene insulation are two different materials with distinct properties and uses. Fiberglass mat tissue is a woven or non-woven fabric made from glass fibers. It is commonly used as a reinforcement material in various applications such as roofing, pipes, and automotive parts. Fiberglass mat tissue provides excellent strength, durability, and resistance to moisture and chemicals. On the other hand, polystyrene insulation refers to rigid foam boards or expanded polystyrene (EPS) beads used for thermal insulation purposes. Polystyrene insulation offers high thermal resistance, making it an effective material for insulating buildings and reducing energy consumption. Comparing the two, fiberglass mat tissue is primarily used for reinforcement and structural purposes, whereas polystyrene insulation is specifically designed for thermal insulation. The choice between them depends on the specific requirements of the application, such as the need for structural strength or thermal efficiency.

- Q: How does fiberglass mat tissue perform in terms of thermal resistance?

- Fiberglass mat tissue performs exceptionally well in terms of thermal resistance. Due to the inherent properties of fiberglass, such as low thermal conductivity and high melting point, the mat tissue effectively acts as a barrier against heat transfer. It efficiently blocks the conduction of heat, limiting thermal energy from passing through the material. This makes fiberglass mat tissue an excellent choice for insulation applications where thermal resistance is crucial, such as in buildings, industrial equipment, and automotive components. Additionally, fiberglass mat tissue is known for its fire-resistant properties, further enhancing its ability to withstand high temperatures and provide excellent thermal insulation.

- Q: Can fiberglass mat tissue be used for reinforcing pipes?

- Yes, fiberglass mat tissue can be used for reinforcing pipes. Fiberglass mat tissue is made of fine glass fibers that are randomly oriented, giving it excellent strength and flexibility. This makes it an ideal material for reinforcing various structures, including pipes. When applied to the surface of a pipe, the fiberglass mat tissue helps to increase its overall strength and durability, preventing cracks and leaks. Additionally, fiberglass mat tissue is resistant to corrosion, making it suitable for use in pipes that carry corrosive substances. Overall, fiberglass mat tissue is a reliable choice for reinforcing pipes and ensuring their long-term performance.

- Q: Can fiberglass mat tissue be painted over?

- Yes, fiberglass mat tissue can be painted over. However, there are a few considerations that need to be taken into account. First, it is important to ensure that the fiberglass mat tissue is clean and free from any dirt, grease, or other contaminants before painting. This can be achieved by cleaning the surface with a mild detergent and water, followed by thorough rinsing and drying. Secondly, it is recommended to apply a primer before painting to improve adhesion and promote a smoother finish. A high-quality primer specifically designed for use on fiberglass surfaces should be used, following the manufacturer's instructions for application. Finally, when choosing the paint, it is crucial to select one that is compatible with fiberglass materials. Acrylic or epoxy-based paints are often recommended as they provide good adhesion and durability on fiberglass surfaces. By following these steps and using appropriate materials, it is possible to paint over fiberglass mat tissue successfully. However, it is always advisable to consult with a professional or follow the manufacturer's recommendations for optimal results.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 800gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords