Fiberglass Mat Tissue Free Sample Offered Glass Wool Board/Glass Wool Insulation/Glass Wool Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property. Glass wool blanket, glass wool board, glass wool pipe, which made from glass wool, largely use in construction, chemical, electronic, electricity, metallurgy, energy industry and community with good performance in heat preservation, heat insulation, sound absorption.

2.Main features of Glass Wool Blanket:

1) Heat-preservation and heat-insulation, sound absorption and noise reduction

2) Damp proof property

3) Excellent fire proof performance

4) Thermal stability, high temperature heat-stability, durability, high temperature shrinkage resistance

5) Non-poison, not contain rock wool and not grow the mould

6) Thin and long inner fiber

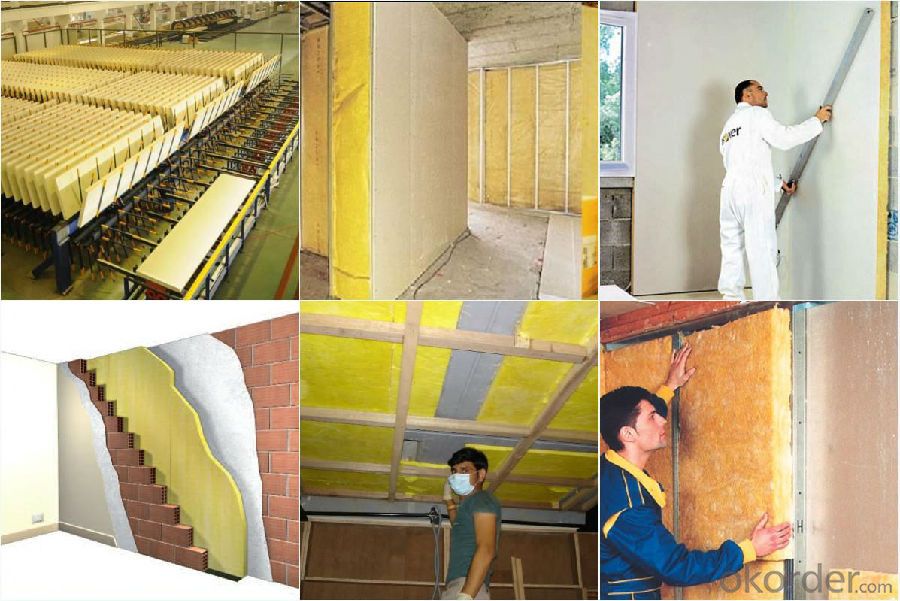

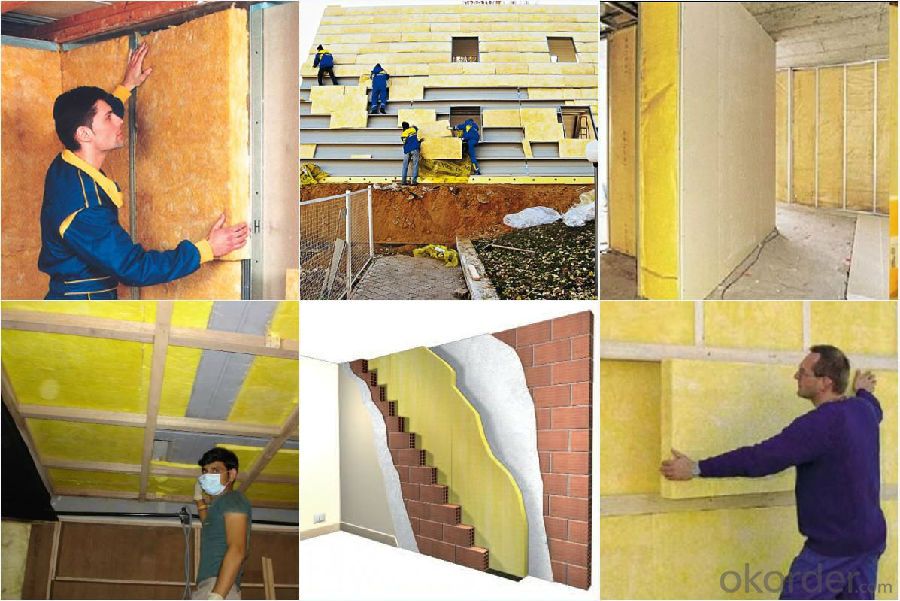

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can fiberglass mat tissue be used for mold making?

- No, fiberglass mat tissue is not typically used for mold making. Fiberglass mat tissue is a thin, lightweight material made from woven fiberglass strands. It is mainly used for reinforcing and strengthening composite materials, such as fiberglass laminates. For mold making, materials such as silicone rubber, urethane rubber, or latex are commonly used. These materials are flexible and can capture intricate details, making them ideal for creating molds of objects. Additionally, they have good release properties, which allow for easy removal of the mold from the original object. Fiberglass mat tissue, on the other hand, is rigid and does not have the flexibility required for mold making. It is more suitable for applications where strength and reinforcement are needed, rather than capturing detailed shapes or creating molds. Therefore, if you are looking to make molds, it is recommended to choose a material specifically designed for that purpose, rather than using fiberglass mat tissue.

- Q: Is fiberglass mat tissue safe to handle?

- Yes, fiberglass mat tissue is generally safe to handle. However, it is important to take certain precautions when handling fiberglass to minimize any potential risks. Fiberglass mat tissue is made up of fine fibers of glass, and if not handled properly, these fibers can become airborne and may cause irritation to the skin, eyes, and respiratory system. To ensure safety, it is recommended to wear personal protective equipment such as gloves, safety goggles, and a dust mask when handling fiberglass mat tissue. This will help prevent direct contact with the skin, eyes, and inhalation of any loose fibers. It is also advisable to work in a well-ventilated area to reduce the concentration of airborne fibers. In addition, it is essential to handle fiberglass mat tissue with care to prevent any physical injuries. The fibers can be sharp and may cause cuts or abrasions if mishandled. It is advisable to use appropriate tools and techniques to cut, shape, or manipulate the material. Furthermore, it is important to follow proper disposal guidelines for fiberglass waste. Avoid sweeping or vacuuming the area where fiberglass mat tissue has been handled, as this can disperse fibers into the air. Instead, use damp cleaning methods or specialized vacuum cleaners with HEPA filters to contain the fibers and reduce the risk of exposure. By following these safety precautions and handling guidelines, the risks associated with fiberglass mat tissue can be effectively minimized, ensuring safe handling and use of the material.

- Q: What are the advantages of using fiberglass mat tissue?

- The advantages of using fiberglass mat tissue include its high strength-to-weight ratio, excellent dimensional stability, resistance to corrosion, and ability to provide reinforcement to various materials. Additionally, fiberglass mat tissue is easy to handle and can be easily molded or shaped to fit different applications, making it a versatile choice in industries such as construction, automotive, and aerospace.

- Q: Can fiberglass mat tissue be used for repairing fiberglass boats?

- Yes, fiberglass mat tissue can be used for repairing fiberglass boats. It is commonly used in boat repairs to reinforce weak or damaged areas and provide strength and durability to the repaired sections.

- Q: Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a lightweight material that offers excellent thermal insulation properties. It can effectively trap heat and prevent it from escaping, making it suitable for creating insulation jackets that provide warmth and insulation.

- Q: Is fiberglass mat tissue suitable for marine applications?

- Fiberglass mat tissue is indeed appropriate for marine applications. Its durability, strength, and ability to resist water and corrosion make it a popular choice in the marine industry. This lightweight material is perfect for boat construction and repairs. It also offers exceptional resistance against UV rays, chemicals, and harsh weather conditions commonly found in marine environments. Additionally, it provides outstanding structural reinforcement and can be easily shaped and molded to suit different marine components. All in all, fiberglass mat tissue is a dependable and adaptable material for marine uses.

- Q: Can fiberglass mat tissue be used for reinforcing wind turbine blades?

- Yes, fiberglass mat tissue can be used for reinforcing wind turbine blades. It is commonly utilized in the manufacturing process as it provides strength, durability, and flexibility to the blades, making them more capable of withstanding the forces and stresses experienced during operation.

- Q: How is fiberglass mat tissue manufactured?

- Fiberglass mat tissue is manufactured by first combining glass fibers with a binder material, usually a water-based emulsion. This mixture is then spread onto a conveyor belt or drum and passed through an oven to dry and cure the binder. The resulting mat is then rolled or cut into the desired dimensions and can be further processed or used as a reinforcement material in various industries such as construction, automotive, and aerospace.

- Q: How is fiberglass mat tissue used in the production of storage containers?

- Fiberglass mat tissue is commonly used in the production of storage containers to reinforce and strengthen the structure. It is typically applied as a layer between the layers of resin and fiberglass to improve the container's durability and resistance to cracking or breaking. The fiberglass mat tissue acts as a reinforcement material, providing additional strength and stability to the container, making it more suitable for heavy-duty storage purposes.

- Q: How does fiberglass mat tissue compare to fiberglass mesh?

- Fiberglass mat tissue and fiberglass mesh serve different purposes and exhibit distinct characteristics. Fiberglass mat tissue, a lightweight and flexible material, finds common use in the production of fiberglass-reinforced plastics (FRP). It is created by randomly dispersing glass fibers onto a mesh or non-woven fabric, which is then bonded with resin. This yields a material with a smooth surface and higher tensile strength compared to fiberglass mesh. Its exceptional strength and stiffness make it an ideal choice for applications that necessitate structural reinforcement, such as automotive parts, boat hulls, and wind turbine blades. Conversely, fiberglass mesh is a woven fabric composed of continuous glass fibers. With its open mesh structure, it facilitates better resin penetration and adhesion. Fiberglass mesh is frequently employed to reinforce surfaces like concrete, stucco, and drywall. It offers excellent crack resistance, dimensional stability, and impact resistance. In construction and renovation projects, fiberglass mesh proves particularly valuable as it reinforces surfaces and prevents cracking. In conclusion, fiberglass mat tissue is better suited for applications requiring structural reinforcement and strength, like FRP production. Its smooth surface and high tensile strength set it apart. On the other hand, fiberglass mesh is commonly used in construction projects to reinforce surfaces and prevent cracking. Its open mesh structure allows for improved resin penetration and adhesion. Ultimately, the choice between fiberglass mat tissue and fiberglass mesh depends on the specific requirements of the application at hand.

Send your message to us

Fiberglass Mat Tissue Free Sample Offered Glass Wool Board/Glass Wool Insulation/Glass Wool Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords