Fiberglass Mat Tissue Glass Wool Blanket, Batts/ Glasswool Insulation Keba (Manufacture)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

The glass wool blanket is applied for large laying area. Besides the character of thermal insurance, it

also has the performances of shock absorption and acoustical isolation, especially for middle or low

frequency sound. It also can cancel the noise and improve working environment.

The glass wool blanket with aluminum foil surface has good capability of heat radiation protection.

2.Main features of Glass Wool Blanket:

1) Heat-preservation and heat-insulation, sound absorption and noise reduction

2) Damp proof property

3) Excellent fire proof performance

4) Thermal stability, high temperature heat-stability, durability, high temperature shrinkage resistance

5) Non-poison, not contain rock wool and not grow the mould

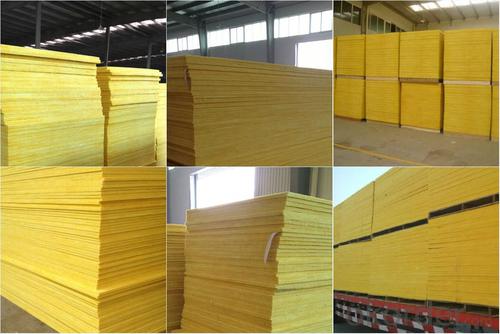

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Technical Description

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue chemically resistant?

- Yes, fiberglass mat tissue is chemically resistant. Fiberglass mat tissue is made from fine glass fibers that are randomly oriented and bound together with a resin binder. This composition allows the material to exhibit excellent resistance to a wide range of chemicals including acids, alkalis, solvents, and oils. It is commonly used in industries such as chemical processing, petrochemicals, and wastewater treatment where exposure to various chemicals is common. The chemical resistance of fiberglass mat tissue makes it a suitable choice for applications requiring corrosion resistance and long-term durability.

- Q: What are the factors that affect the diameter of electrospun nanofibers?

- Application of drug controlled release, tissue engineering, the application of biomimetic materials and artificial organs, sensor film principle: electrospinning is a polymer solution (or melt) forming process of fiber in high voltage field, its core is to take charge of the polymer solution or melt flow and deformation in electrostatic field, and then by solvent evaporation or melt cooling and solid...

- Q: What are the different reinforcement densities available for fiberglass mat tissue?

- The different reinforcement densities available for fiberglass mat tissue can vary depending on the specific manufacturer and product. However, common options include low density (lightweight), medium density, and high density fiberglass mat tissues. These densities are designed to provide different levels of strength, flexibility, and durability for various applications in industries such as construction, automotive, and marine.

- Q: What is the cost of fiberglass mat tissue?

- The cost of fiberglass mat tissue can vary depending on factors such as the thickness, size, and brand. It is best to check with suppliers or retailers for specific pricing information.

- Q: What are the different weights available for fiberglass mat tissue?

- Fiberglass mat tissue, which is widely used in various industries including construction, automotive, and marine, comes in different weights or thicknesses to cater to different applications and requirements. The weight of fiberglass mat tissue is usually measured in grams per square meter (gsm) or ounces per square yard (oz/yd²). Typically, the weights available for fiberglass mat tissue range from around 30 gsm (1 oz/yd²) to 150 gsm (5 oz/yd²) or even higher. The weight of the tissue determines its strength, rigidity, and durability. Lightweight fiberglass mat tissue, such as those weighing around 30-50 gsm (1-1.5 oz/yd²), is commonly used for applications where a high level of flexibility and conformability is required. These lighter weight tissues are often used in the production of laminates, reinforcing materials, and lightweight composites. Medium weight fiberglass mat tissue, usually ranging from 70 gsm (2 oz/yd²) to 100 gsm (3 oz/yd²), provides a balance between flexibility and strength. It is frequently used in applications such as roofing, insulation, and wall panels, where structural integrity and thermal insulation properties are important. Heavyweight fiberglass mat tissue, which can weigh between 120 gsm (4 oz/yd²) and 150 gsm (5 oz/yd²) or more, offers excellent strength and rigidity. This type of tissue is commonly used in demanding applications like boat hulls, automotive body parts, and industrial equipment, where durability and resistance to impact and stress are crucial. It is important to note that the availability of different weights of fiberglass mat tissue may vary depending on the manufacturer and the specific requirements of the application. In some cases, custom weights can be produced to meet unique project needs. In conclusion, fiberglass mat tissue comes in a range of weights to suit different applications. Choosing the appropriate weight is crucial to ensure optimal performance and long-term durability in various industries.

- Q: Can fiberglass mat tissue be used for repairing fiberglass shower stalls?

- Yes, fiberglass mat tissue can be used for repairing fiberglass shower stalls. It is a commonly used material for reinforcing and repairing fiberglass surfaces, including shower stalls.

- Q: Does fiberglass mat tissue provide any sound insulation?

- Yes, fiberglass mat tissue does provide sound insulation. It is a common material used in various industries, including construction and automotive, to absorb and reduce sound transmission. The fibrous structure of the material helps to trap and absorb sound waves, preventing them from passing through walls or other surfaces. Fiberglass mat tissue is often used as an acoustic insulation material in walls, floors, and ceilings to create a more comfortable and noise-free environment.

- Q: Can fiberglass mat tissue be used for reinforcing wind turbine blades?

- Wind turbine blades can be reinforced using fiberglass mat tissue, a lightweight and flexible material composed of thin glass fibers bonded with resin. This material is frequently employed in various applications requiring strength and durability, including wind turbine blade construction. To efficiently harness wind power, turbine blades must possess strength while remaining lightweight. They face various forces, such as wind loads, vibrations, and extreme weather conditions. Fiberglass mat tissue is an ideal option for reinforcing these blades due to its exceptional mechanical properties. It offers high tensile strength and stiffness, enabling the blades to withstand the stress and strain they encounter during operation. Furthermore, fiberglass mat tissue exhibits excellent resistance to corrosion and fatigue, which are crucial factors for ensuring the long-term performance of wind turbine blades. It also maintains good dimensional stability, preserving the shape and integrity of the blades over time. Moreover, fiberglass mat tissue can be easily shaped and molded, allowing for the creation of complex and aerodynamic blade designs. It can be layered and combined with other materials, such as epoxy resin, to form a composite structure that optimizes the strength and performance of wind turbine blades. In conclusion, fiberglass mat tissue is a widely used and suitable material for reinforcing wind turbine blades. Its lightweight nature, high strength, corrosion resistance, and moldability make it an excellent choice for maintaining the structural integrity and efficiency of wind turbines.

- Q: Can fiberglass mat tissue be used in structural applications?

- Yes, fiberglass mat tissue can be used in structural applications. Fiberglass mat tissue is a lightweight and flexible material that is commonly used as reinforcement in construction and engineering. It is often used in conjunction with other materials such as resin or concrete to enhance the structural integrity of various components. The high strength-to-weight ratio of fiberglass mat tissue makes it ideal for reinforcing structures such as walls, roofs, and floors. Additionally, fiberglass mat tissue is resistant to corrosion, moisture, and chemicals, making it suitable for use in various environments. Its versatility and durability make it a popular choice in structural applications.

- Q: What is the expected lifespan of fiberglass mat tissue in cryogenic applications?

- The expected lifespan of fiberglass mat tissue in cryogenic applications can vary depending on various factors such as the quality of the material, the specific cryogenic environment, and the maintenance and handling practices. Generally, fiberglass mat tissue is known for its excellent insulation properties and resistance to extreme temperatures. It is commonly used in cryogenic applications to provide thermal insulation and structural support. In well-maintained and controlled cryogenic environments, fiberglass mat tissue can have a lifespan of several decades. However, it is important to note that factors such as exposure to intense thermal cycling, mechanical stress, and chemical exposure can affect the performance and lifespan of the material. To ensure the longevity of fiberglass mat tissue in cryogenic applications, regular inspections, maintenance, and adherence to manufacturer's guidelines are crucial. It is also recommended to monitor and address any signs of degradation or damage promptly to prevent potential issues or failures.

Send your message to us

Fiberglass Mat Tissue Glass Wool Blanket, Batts/ Glasswool Insulation Keba (Manufacture)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords