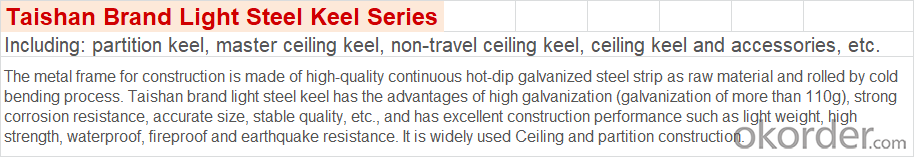

Factory Supply Light Steel Keel T-Bars Galvanized Ceiling T Grid Good Quality Galvanized

- Supplier:

Taishan Gypsum Co., Ltd.

Taishan Gypsum Co., Ltd.

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 60000000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

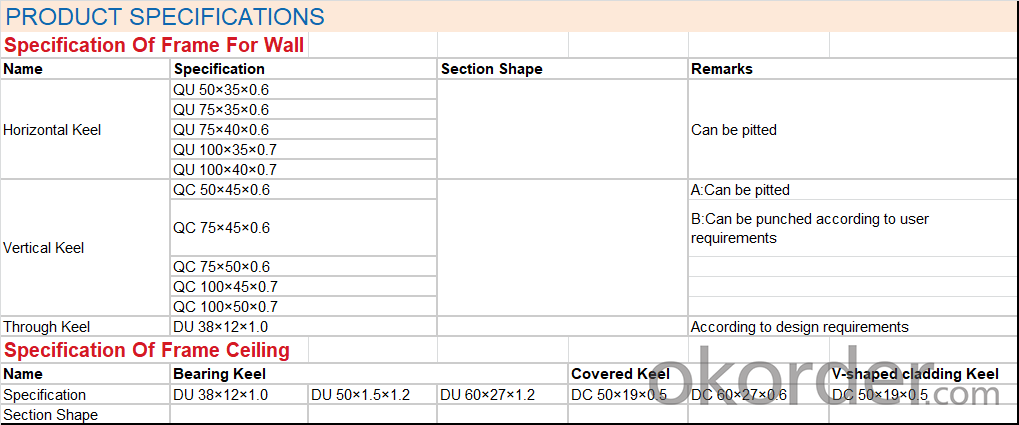

Specification

Thickness:

0.3-1.5mm

Fonction:

Fireproof Board Ceiling,Waterproof Ceiling,Smoke-Proof Ceiling,Mould-Proof Ceiling,Moisture-Proof Ceiling,Heat Insulation Ceiling,Integrated Ceiling,Normal Ceiling,Soundproof Ceiling

Application:

Public,Household,Hotel,Office,Dust Free Room

Shape:

Grille,Square,Rectangle

Material:

Steel

属性名(例如:Metal):

属性值(例如:Metal)

- Q: 75 light steel keel wall to do 6m high, need reinforcement? How to strengthen?

- Main production 75 wall light steel keel, 100 wall light steel keel, ceiling card type main dragon, 50 pay dragon, 50 main dragon, 60 main keel, 60 pay dragon, 38 main dragon, triangular keel, galvanized ceilings , Paint smallpox keel, aluminum wind Tsui, gong rod, the keel accessories and other products.

- Q: Now what is the room wall material is fashionable? Environmentally friendly

- Sound insulation cotton how to be environmentally friendly too old and toxic The best material is lightweight partition wall insulation insulation and non-toxic light foam cement board wallboard calcium silicate partition board and keel plus paint-free green frog Non-toxic dalfers are currently my best found some non-toxic

- Q: What are the consequences of installing a hanging cabinet on gypsum board wall?

- Gypsum board can not load, do not install gypsum board door hanging cabinet. If the impact of drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon penetrate, But it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play wood slag to.

- Q: Light steel keel wall how to calculate

- According to the actual calculation of the amount of work to square meters for the calculation unit, the price of both sides negotiated or set quotas. According to how you talk about the calculation, if not talk, the market is calculated by single-sided!

- Q: 6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- Formal practice, must be done to the top, unless it is not the request, nobody tube project, it may not be the top.

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Yes, because the prefabricated board toughness is better, and its specifications are not the kind of chunks, if the chunk can withstand the weight will be reduced in the middle of the possibility of falling to increase .. Light steel keel wall itself The weight is not heavy, coupled with the ceiling is also force, then the weight of the ground will be reduced accordingly

- Q: Can the gypsum board be painted on the wall

- You can play tuxedo on the keel on the line

- Q: Light steel keel wall Why do not cross brace welding with welding

- Horizontal keel is a secondary support role, the panel position is not time to adjust the location, in addition to the function of contraction expansion margin, so not allowed to link the link for the rigid.

- Q: Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- And traditional wooden keel wall for comparison? Basically, the framework is different, flatness is different, the cost is different.

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board wall of the impact resistance and load-bearing performance is also very good, ordinary furniture hit the wall, no damage, even if the impact of an adult's running jump, no damage, no cracks in the wall, no deformation , The intensity is twice the international standard. Wall load-bearing capacity is unequivocal, the maximum load of 75kg, to meet the needs of most of the majority of the normal use of the family. To the wall hanging paintings, shelves and other daily items, with screws fixed on the wall hanging on OK; hanging TV, air conditioning, hanging cabinets and other heavy objects, just use the expansion bolt to do reinforcement treatment can be used at ease.

Send your message to us

Factory Supply Light Steel Keel T-Bars Galvanized Ceiling T Grid Good Quality Galvanized

- Supplier:

Taishan Gypsum Co., Ltd.

Taishan Gypsum Co., Ltd.

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 60000000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords