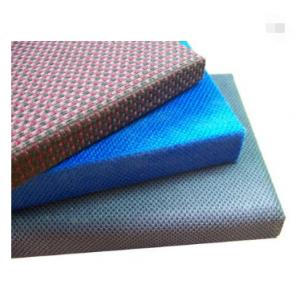

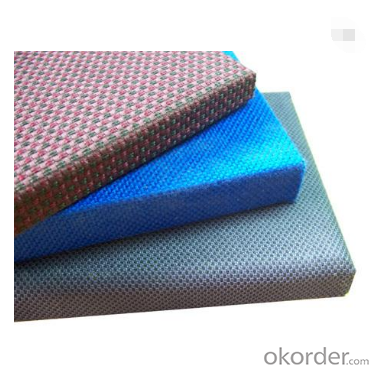

Fabric wrapped fiberglass acoustic wall panel CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fabric wrapped fiberglass acoustic wall panel CNBM

Specification:

Standard Size: 600mm*600mm, 600mm*1200mm…

Standard Thickness: 25, 30, 40, 50mm…

Edge Detail: Square, Bevel

Technical Data of Fiberglass Wall Panel:

Material: Torrefaction compounded high density fiberglass wool

Facing: wrpped with special decorative fabric

Fire-resistant: Base board: Class A, Finished board:Class B2

Humidity: Dimensionally stable with RH up to 90% at 40℃

Environmental: Tiles and packing materials are fully recyclable

Fabric wrapped fiberglass acoustic wall panel CNBM

Main Characteristic of Fiberglass Ceiling:

Excellent sound absorption

No sagging, wrapping or delaminating

Fire-resistant

Moisture resistant

Excellent light reflectance

Cleanable

Environmentally friendly

Application Areas of Fiberglass Ceiling:

Commercial Halls,Classrooms,Offices,Libraries,Shopping Centers,Music Rooms,Auditoriums,etc.

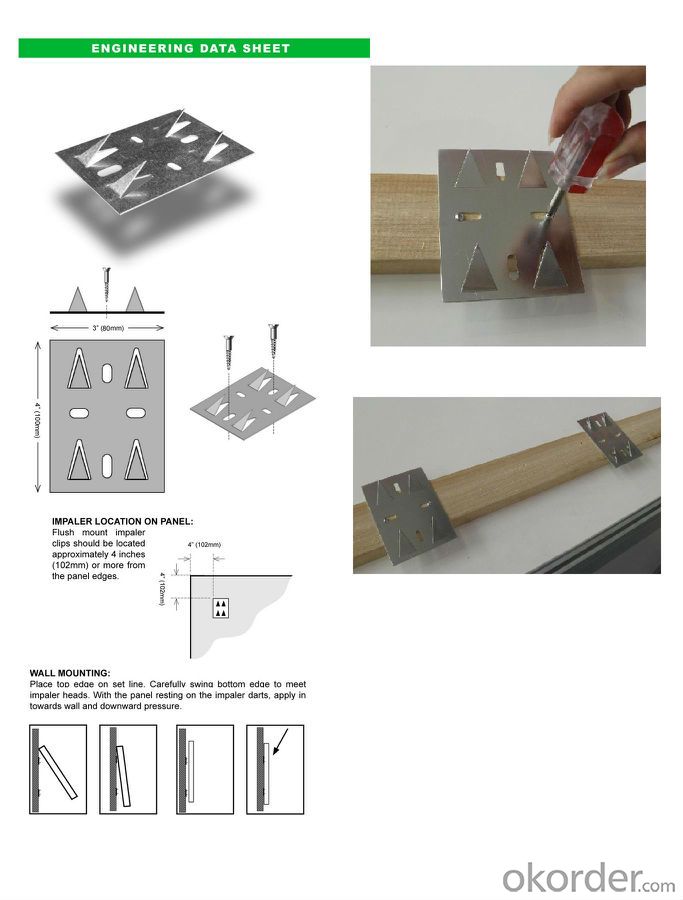

How to install:

Fabric wrapped fiberglass acoustic wall panel CNBM

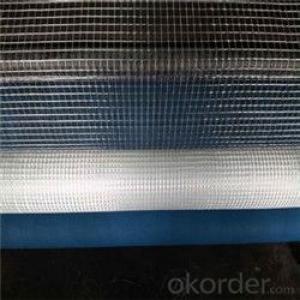

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The general wall of the grid with a fast money about 1 square meters on the good. Tengda grid cloth 8 hair can also be used. Selling is also good,

- Q: How to do with glass fiber wall anti-crack

- Do not have to be fainted by the glass fiber, although the use of glass fiber, the surface can not see the crack, but in fact still strong, no use, their own fool themselves; recommended landlord with anti-cracking latex paint, such as Mo Wei Latex paint, it can be painted when the wall can make up for the small cracks in the wall, and the film after forming a certain degree of flexibility to prevent the emergence of cracks, this effect is only Mo Weier can do, please landlord reference!

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- If only the local cracks, you can also use ordinary straps paste.

- Q: What is the quality of the light barrier now?

- . Increased use of building area: the wall can increase the use of an area of 8-10% or more, is the property development buyers and sellers are happy to accept.

- Q: What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- Lightweight aggregate concrete partition board: is made of lightweight aggregate concrete slab, which is suitable for ordinary building grade. Lightweight aggregate concrete is made of natural light aggregate (such as pumice) or artificial light aggregate (such as ceramic) or industrial waste light aggregate (such as slag beads) plus cement and water mixed with concrete. Lightweight aggregate concrete and ordinary concrete is the difference between light aggregate concrete without stones, and some of his aggregate can float on the water.

- Q: What is grc widget

- Now the domestic grc component manufacturers in the rising, but do a lot better to do a few, Guangzhou Shengfan building materials is one of them

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- Fiber mesh, also known as reticular fiber, reticular polypropylene fiber, is a polypropylene as raw material, through a special process from manufacturing. The appearance of a number of fiber monofilament cross-linked from the network structure.

- Q: Wall material that kind of environmental protection?

- Glass fiber wall cloth, that is, wall fabric, the function is relatively strong, it is made of glass fiber, not only environmentally friendly, and fire anti-cracking moisture, scrub resistance, good care, life of more than 10 years. Whether the project or home improvement is a good choice.

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production process of glass fiber generally includes: raw material procurement, according to the formula for mixing, and then transported to the glass furnace for melting, clarification, through the operating channel flow to the drawing board, sizing agent after drawing through the drawing machine to form the original wire (Usually with yarn, weaving, chopping, puffing, twisting, etc.) or for sale (direct yarn)

- Q: Grc light partition board construction steps is what

- Partition board positioning, elastic line According to the construction drawings, in the installation of partition board, that is, the column side, ground, ceiling, beam bottom and the GRC light wall panels and other thickness of the two parallel ink line, and marked the door and window openings, Parallel to the side of the ink line 100mm pop up a parallel to the wall of the first three ink lines, as the inspection control line, after the installation of the partition to check the location of the partition is correct.

Send your message to us

Fabric wrapped fiberglass acoustic wall panel CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches