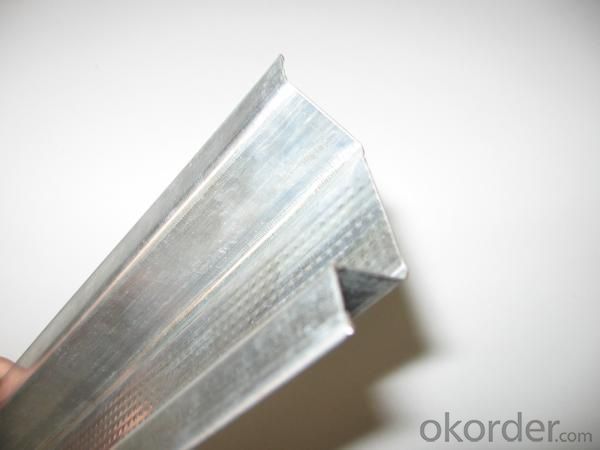

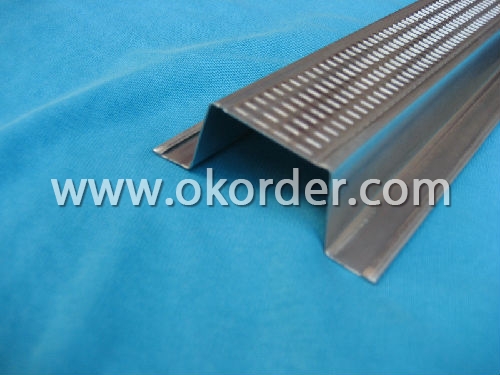

Steel Profile for Ceiling Tiles

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Container m

- Supply Capability:

- 30 Containers/Month m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

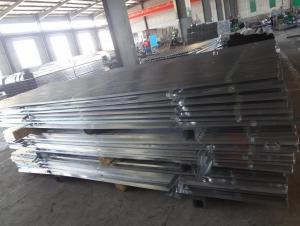

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q: In Shanghai 75 partition wall light steel keel 0.6 what price now

- The general keel material costs 34 or so manual 15 that you look at the offer

- Q: What are the consequences of installing a hanging cabinet on gypsum board wall?

- Gypsum board can not load, do not install gypsum board door hanging cabinet. If the impact of drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon penetrate, But it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play wood slag to.

- Q: Who used the light steel keel gypsum board to do the wall?

- The sound insulation effect than the brick or a little worse but have their own advantages and disadvantages of the small space that is also cheaper than the brick wall is suitable for wardrobe compartment

- Q: Light steel keel wall circuit how to wear pipe

- Install the crossed keel (lower threshold). Fixed with a nail, or first drilling, and with the expansion bolts connected to fixed. Installation should be installed according to the center line and edge, both ends of the top to the structural wall (column) surface, the final fixed point from the structure of the facade should not be greater than 100mm; nail or expansion bolt spacing should not be greater than 800mm. Installation should ensure that the keel level and straightness.

- Q: Light steel keel should be how to strengthen, in order to make solid wood door installed more prison?

- Has been reinforced with wood, had not wanted to choose light steel keel is not considered too tight, not the reason for noise, but because these two bolt doors are not out from the original wall, decorating company recommended with light steel keel, So I did not insist, but there are 2 stack walls I insist they use brick

- Q: Lightweight wallboard light steel keel how to construction

- Light ends of the keel should be installed firmly, keel and the base of the fixed point spacing should not be greater than one meter, installed through the series keel, less than three meters of the partition to install a three to five meters installed two When the transverse joints are not on the edge, along the top keel, should be added to the dragon keel fixed, doors and windows or special joints to install additional keel should meet the design requirements of the skeleton wall in the installation of decorative panels should check the firmness of the skeleton , Whether the installation of wall equipment, pipeline and filling materials meet the design requirements If there is a non-compliance should take measures. Light wall panels The installation process as long as the step by step, the order of work also need to be more cautious.

- Q: Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- It is quite possible that this practice is very common. In the office building decoration, it will often use this method to do with the installation of glass. Just, light steel keel need to use gypsum board to do the surface closed, and with latex paint in the final decoration.

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- Do of course But I suggest do not do it! You do not want to move the floor, you put the floor cut off the partition of the piece. Directly to the disadvantages: 1: wooden floor flexible, partition instability. 2: you are not bad when the wall and the floor shut. 3: sound insulation is certainly worse

- Q: How to do woodworking partition wall, with door

- Wood keel partition wall inspection standards: the size of the partition is correct, the material specifications are consistent: the wall straight, smooth, corner of the orthogonally close F along the ground, along the top of the wood and the edge of the wall, Firm and straight. Check the partition wall, with 2 m ruler detection, the surface roughness error is less than 2 mm, vertical plane tolerance is less than 3 mm, seam height difference is less than 0.5 mm.

- Q: Light steel keel partitions and finished partitions

- Light steel keel partition is one of the most common decoration projects in the field of decoration and decoration. It is made of light steel keel as the basic skeleton, the surface gypsum board is made of wall layer and fixed to the top and top of the building. Wall; it needs to use talcum powder, such as putty layer, latex paint or wallpaper as a surface decoration, are produced on-site.

1. Manufacturer Overview

| Location | Bazhou, China |

| Year Established | 1994 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | China; Russia; the US; France; Germany; Japan; South Korea; the Middle East; Southeast Asia; Australia; South Africa and many other countries and regions |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 12000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | High and/or Average |

Send your message to us

Steel Profile for Ceiling Tiles

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Container m

- Supply Capability:

- 30 Containers/Month m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords