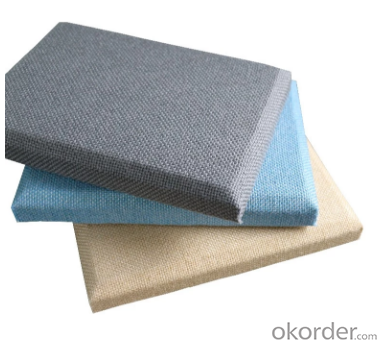

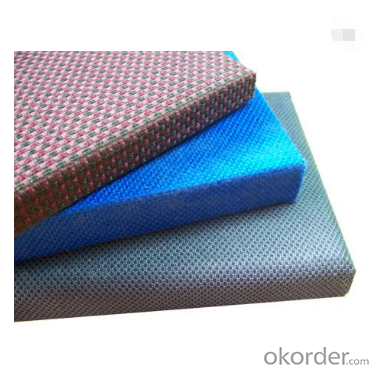

Fiberglass acoustic wall panel with fabric Facing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass acoustic wall panel with fabric Facing

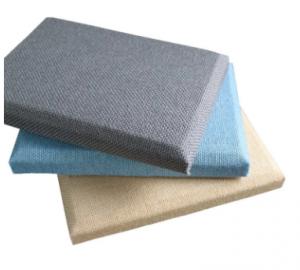

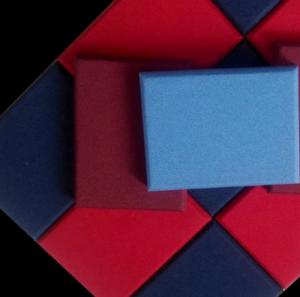

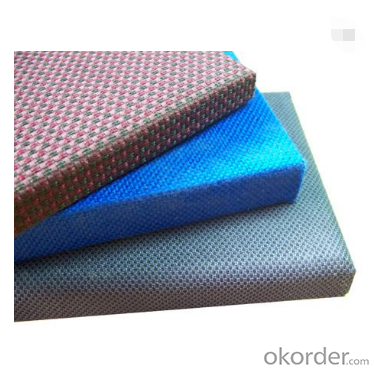

Specification:

Standard Size: 600mm*600mm, 600mm*1200mm…

Standard Thickness: 25, 30, 40, 50mm…

Edge Detail: Square, Bevel

Technical Data of Fiberglass Wall Panel:

Material: Torrefaction compounded high density fiberglass wool

Facing: wrpped with special decorative fabric

Fire-resistant: Base board: Class A, Finished board:Class B2

Humidity: Dimensionally stable with RH up to 90% at 40℃

Environmental: Tiles and packing materials are fully recyclable

Fiberglass acoustic wall panel with fabric Facing

Main Characteristic of Fiberglass Ceiling:

Excellent sound absorption

No sagging, wrapping or delaminating

Fire-resistant

Moisture resistant

Excellent light reflectance

Cleanable

Environmentally friendly

Application Areas of Fiberglass Ceiling:

Commercial Halls,Classrooms,Offices,Libraries,Shopping Centers,Music Rooms,Auditoriums,etc.

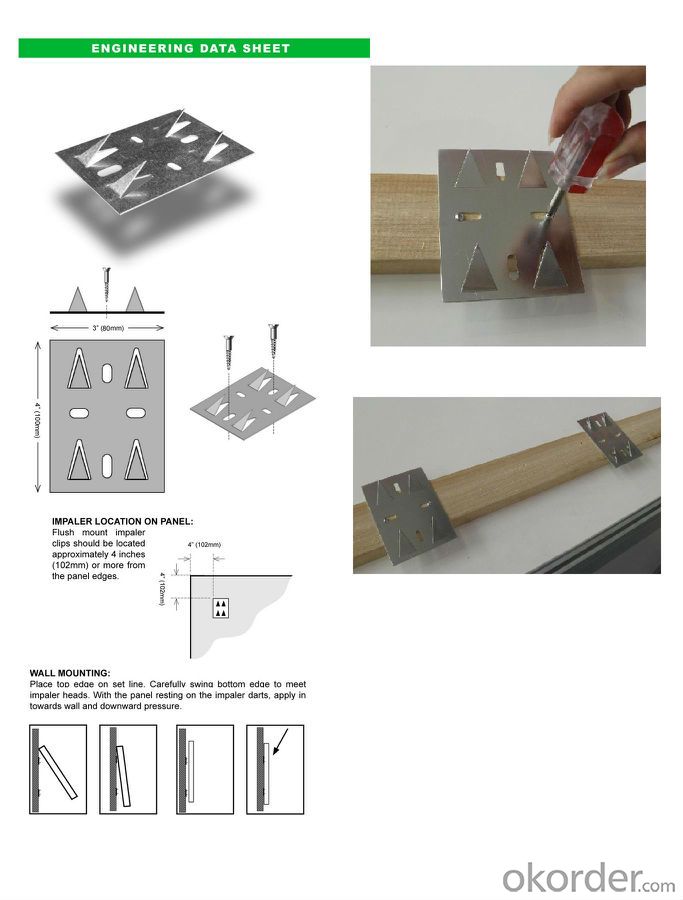

How to install:

Fiberglass acoustic wall panel with fabric Facing

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound absorption, sound insulation, insulation, ring glass board ceiling construction process

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The general wall of the grid with a fast money about 1 square meters on the good. Tengda grid cloth 8 hair can also be used. Selling is also good,

- Q: How to do with glass fiber wall anti-crack

- For glass fiber is also used to see you are used in the external walls or interior walls, wall materials are different, a lot of things are not applicable once. Do not apply their own norms. And a slap to shoot the whole law

- Q: What is the quality of the light barrier now?

- 1. Thermal insulation performance: insulation than the thickness of 570mm brick wall, can greatly reduce the cooling and heating and other electricity, burning costs, can be described as the best choice for energy conservation. 2. Construction speed: easy to install, more than 8 times faster than the concrete pouring method; wall panels can be sawed, can be nailed, drillable, can be arbitrarily cut, free manufacturing structure. 3. Soundproof and waterproof fire performance: sound insulation up to 45dB, the plate has a self-waterproof function, fire resistance of 2.5 hours or more. Anti-freeze-thaw cycle more than 25 times, moisture-proof performance testing projects have reached the national standard.

- Q: What are the lightweight wallboard materials?

- Light wall material as a new type of product, technology is still in the process of the evening, this period inevitably there are some quality problems, affecting its promotion. In the long run, due to the wall material has embarked on a thin body, light, functional diversification (insulation, sound insulation) of the road of innovation, light wall panels will be developed as the country, as a wall material leading.

- Q: What is GRC and can I paint it?

- GRC is also called grc components, refers to the fiberglass made of component-type material, grc shape is based on the external wall of the cad drawings to design, generally do not recommend making paint, grc's exterior decoration has its own treatment.

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- The role of fiber web: Cement concrete for the reticular fiber into the concrete, the concrete mixing process, the fiber optic cable between the horizontal connection can be the concrete's own rubbing and friction play a role in the formation of fiber monofilament or mesh structure fully open, thus To achieve a large number of polypropylene fiber monofilament to play the effect of cracking. Cement concrete special mesh fiber is extremely effective in controlling the plastic shrinkage, shrinkage, temperature change and other factors caused by micro-cracks, to prevent and inhibit the formation and development of cracks. As a new concrete with anti-cracking fiber, concrete with cement concrete mesh fiber is becoming the glass fiber, steel fiber fiber concrete industry research and application of hot

- Q: Wall material that kind of environmental protection?

- Now environmentally friendly materials are relatively more latex paint and wall cloth are good, but the use of life is limited, weak base of diatom mud to do not only environmental protection can also be used for more than 20 years, is now popular new materials.

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The composite material is mainly composed of two parts: the reinforcing material and the base material: Reinforcing material: does not constitute a continuous phase in the composite material to the main mechanical properties of composite materials, such as fiberglass in the glass fiber, CFRP (carbon fiber reinforced plastic) in the carbon fiber is reinforced. A resin in a single material, such as glass fiber reinforced plastic (GRP), which constitutes a continuous phase of a composite material, is a matrix. Y

- Q: Grc light partition board construction steps is what

- Clean up construction operations In order to ensure the smooth construction of the GRC lightweight partition board, clean up the cleaning parts of the partition board in time and remove the debris from the ceiling, the wall and the mortar blocks protruding from the cylinder, and then rinse the upper part with water Of the floating ash and sand, and dry, and then check the flatness of the site to ensure that the floor of the ground formation, for high and low depression more than 40mm parts should be leveling.

Send your message to us

Fiberglass acoustic wall panel with fabric Facing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches