Fiberglass Decorative Wall Panel Sound Insulation Wall Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

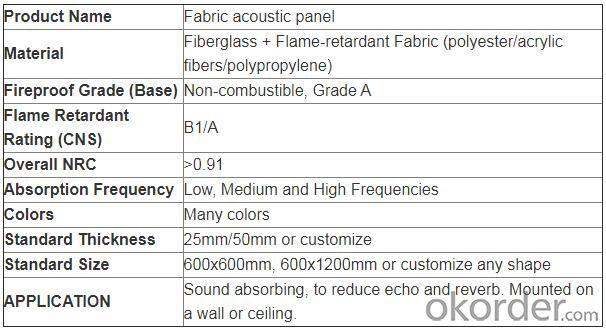

Specification

Description

Fiberglass acoustic panels are made of acoustic fiber and fabric or leather on surface, have excellent soundproof performance in both mid and high frequency. They are decorative and easy to installed. The fabrics on the surface are available in different colors and patterns. Customized is acceptable, you can also provide your own fabrics and designs.

Specification

Application

It is recommended that the Fiberglass Acoustic Wall Panels be installed to the opposite two walls to control the echo of the surroundings. The panels are widely used in Commercial Halls, Classrooms, Offices, Librairies, Shopping Centers, Music Rooms, Auditoriums, etc.where have special request for sound absorption.

Product Features

Environmental protection

Fire proof

Light weight

Whole frequency sound absorption, especially medium-high frequency

High decorative performance diversified colors and and grains

Anti-microbial

Easy installation

Formaldehyde free, dust free

Customization available upon request

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 4 weeks after receiving of downpayment

Picture

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound absorption, sound insulation, insulation, ring glass board ceiling construction process

- Q: How to do with glass fiber wall anti-crack

- First look at what is the wall, is the load-bearing walls, non-load-bearing walls, as well as the original wall is now there are cracks? Do the best way to do anti-crack wall is to shovel the original wall shovel, a plaster leveling or low-level gypsum leveling, after drying in the use of ecological white latex patch, cloth to use really good, so you can prevent the wall The surface is cracked.

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- If the walls of the cracks are more words, you can use the grid covered with paste, and then batch of putty construction;

- Q: What is the quality of the light barrier now?

- The partition board includes glass fiber reinforced concrete slab, glass fiber reinforced gypsum hollow slab, steel wire (steel mesh) reinforced concrete slab, light concrete slab, composite sandwich light bar and so on. The full name is the building wall with a light strip, as a general industrial buildings, residential buildings, public works of non-load-bearing wall of the main material. It is a lightweight partition project which is a non-bearing internal wall of a commercial building, a residential building and a public building project with a light partition.

- Q: What are the lightweight wallboard materials?

- Light wall material as a new type of product, technology is still in the process of the evening, this period inevitably there are some quality problems, affecting its promotion. In the long run, due to the wall material has embarked on a thin body, light, functional diversification (insulation, sound insulation) of the road of innovation, light wall panels will be developed as the country, as a wall material leading.

- Q: What should the overall wardrobe design should have?

- 1, wardrobe side panels and laminates and other places need to bear the weight of 18mm thickness of the three polyamine in the density of fiberboard, the cabinet board to the national authority of the test report, in line with national mandatory standards GB18584-2001 standard, formaldehyde release The amount of ≤ 1.5mg / L, moisture content between 5-11; backplane does not require load-bearing, you can use 5mm thick to make, this can save costs, conditions permit, the door and backplane thickness should be 9mm. For the hanging cabinet, the back plate on the need to use 18mm thickness, density standard 0.6-0.9g / cm3, to enhance the stability of the hanging cabinet; ???? 2, although the overall wardrobe is tailor-made products, but there are standard and non-standard points, the standard parts is the manufacturer in accordance with the specifications of the plate to calculate the production, you can achieve maximum use of the board, the edge is generally uniform, Black line and sawtooth printed; non-standard parts will waste a lot of sheet metal, so the price, non-price will be more expensive;

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- The current state to promote the third generation of environmentally friendly energy-saving partition board, with moisture, earthquake noise, fire insulation, small footprint, good strength, fast construction and other advantages.

- Q: What is grc widget

- Now the domestic grc component manufacturers in the rising, but do a lot better to do a few, Guangzhou Shengfan building materials is one of them

- Q: Wall material that kind of environmental protection?

- Now environmentally friendly materials are relatively more latex paint and wall cloth are good, but the use of life is limited, weak base of diatom mud to do not only environmental protection can also be used for more than 20 years, is now popular new materials.

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production of glass fiber is "clay crucible method", "platinum on behalf of the crucible method", "pool kiln" three methods. "Clay crucible method" is the most primitive process, the main raw materials for the waste glass, the process of high energy consumption, poor product quality, is the state out of the prohibition of the process. "Platinum crucible method" is currently widely used in the process, the raw material for the glass ball. "Pool kiln" is the most advanced technology, its raw materials are "pyrophyllite" mainly mineral powder mixture.

Send your message to us

Fiberglass Decorative Wall Panel Sound Insulation Wall Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords