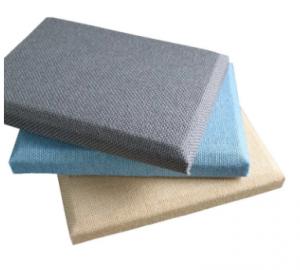

Fiberglass Acoustic Wall Panel

- Loading Port:

- SHANGHAI, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 10000 M2 per month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Wall Panel is consist of a high-density fiberglass core and different items and colors of fabrics. The panel has perfect acoustic performance from low to high frequency noise absorbing, and excellent decorative effect. Available in various sizes / edges / fabrics, and for further digital printingon the fabrics.

Technical Data of Fiberglass Wall Panel:

Material: High density dry felt resin bonded fiberglass wool

Facing: Different items and colors of fabrics

Fire-resistant: Class A, non-combustible tested overseas

Humidity: Dimensionally stable with RH up to 95% at 40℃

Environmental: Panels and packing materials are fully recyclable

Main Characteristic of Fiberglass Wall Panel:

Excellent sound absorption

Fire-resistant

Moisture resistant

Cleanable and recyclable

Environmentally friendly

Application Areas of Fiberglass Wall Panel:

Offices, schools, libraries, hotels, cinemas, theaters, etc., where have special request for sound aborption

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The first floor said yes. I feel it In the use of grid cloth at the same time you have to look at the quality of grid cloth.

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- If the walls of the cracks are more words, you can use the grid covered with paste, and then batch of putty construction;

- Q: What is the quality of the light barrier now?

- 1. Thermal insulation performance: insulation than the thickness of 570mm brick wall, can greatly reduce the cooling and heating and other electricity, burning costs, can be described as the best choice for energy conservation. 2. Construction speed: easy to install, more than 8 times faster than the concrete pouring method; wall panels can be sawed, can be nailed, drillable, can be arbitrarily cut, free manufacturing structure. 3. Soundproof and waterproof fire performance: sound insulation up to 45dB, the plate has a self-waterproof function, fire resistance of 2.5 hours or more. Anti-freeze-thaw cycle more than 25 times, moisture-proof performance testing projects have reached the national standard.

- Q: What should the overall wardrobe design should have?

- Wardrobe door panels are glass, sheet and other materials, glass thickness of 5mm, the texture of frosted glass, clear glass, cloth glass and embossed glass and other options.

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- The current state to promote the third generation of environmentally friendly energy-saving partition board, with moisture, earthquake noise, fire insulation, small footprint, good strength, fast construction and other advantages.

- Q: What is grc widget

- GRC (Glass-fiber Reinforced Cement) glass fiber reinforced cement composite material abbreviation, from the European and American technology, is to alkali-resistant glass fiber, cement, sand and other composite materials according to a certain ratio of mixing, in the mold watering molding, production Modeling rich, texture and diverse products, are widely used in domestic and international characteristics of the building.

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- The role of fiber web: Cement concrete for the reticular fiber into the concrete, the concrete mixing process, the fiber optic cable between the horizontal connection can be the concrete's own rubbing and friction play a role in the formation of fiber monofilament or mesh structure fully open, thus To achieve a large number of polypropylene fiber monofilament to play the effect of cracking. Cement concrete special mesh fiber is extremely effective in controlling the plastic shrinkage, shrinkage, temperature change and other factors caused by micro-cracks, to prevent and inhibit the formation and development of cracks. As a new concrete with anti-cracking fiber, concrete with cement concrete mesh fiber is becoming the glass fiber, steel fiber fiber concrete industry research and application of hot

- Q: Wall material that kind of environmental protection?

- Glass fiber wall cloth, that is, wall fabric, the function is relatively strong, it is made of glass fiber, not only environmentally friendly, and fire anti-cracking moisture, scrub resistance, good care, life of more than 10 years. Whether the project or home improvement is a good choice.

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production of glass fiber is "clay crucible method", "platinum on behalf of the crucible method", "pool kiln" three methods. "Clay crucible method" is the most primitive process, the main raw materials for the waste glass, the process of high energy consumption, poor product quality, is the state out of the prohibition of the process. "Platinum crucible method" is currently widely used in the process, the raw material for the glass ball. "Pool kiln" is the most advanced technology, its raw materials are "pyrophyllite" mainly mineral powder mixture.

- Q: Grc light partition board construction steps is what

- 1, the process Material inspection → technology to the end of the net → clean-up → line → fixed U-shaped steel plate card → live installation → detection of vertical, flatness → fixed GRC light partition board → repeat the vertical degree, flatness → support pipe → tied to the joints with → seam mortar → scraping putty → polished smooth → surface coating. The following are the same as the " 2, prepare materials and construction tools Before the construction, need to prepare GRC lightweight partition board materials and doors and windows supporting frame bench material, and to prepare construction tools, such as temporary fixed fixture "U" type fixture, "L" type fixture, to be horizontal angle iron Of the pry bar, woodworking board saw, putty knife, wooden wedge and so on. The following are the same as the " According to the requirements of the drawings, in the wall and the roof pop-up wall and the location of the doors and windows. And the office, corridors, halls and other rooms are ceiling, so the need for height in the partition wall to do hanging columns and hanging beams.

Send your message to us

Fiberglass Acoustic Wall Panel

- Loading Port:

- SHANGHAI, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 10000 M2 per month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords