Extrusion Aluminum Profiles for Aluminium T-Profile Windows and Doors Installation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium T-profile for Windows and Doors Instalation Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium T-profile for Windows and Doors Instalation:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

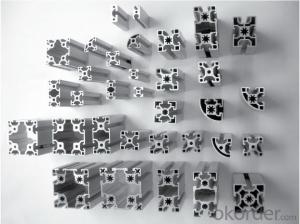

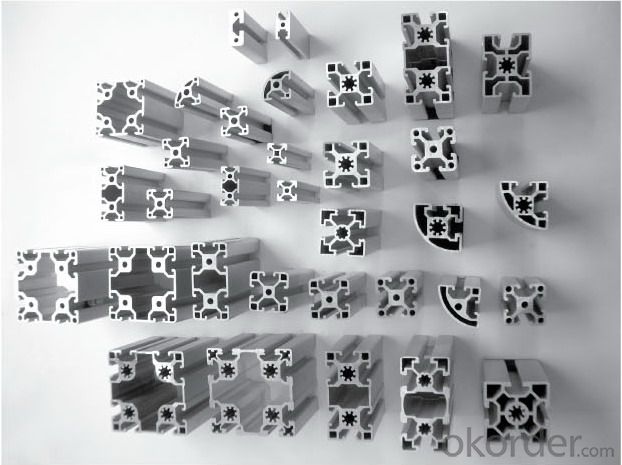

Images of the Aluminium T-profile for Windows and Doors Instalation:

Aluminium T-profile for Windows and Doors Instalation Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: how to determine its value? After these scrap to foundry on the 30...Emergency: the scrap aluminum production enterprises how to conduct accounting treatment, how to determine its value? After the aluminum foundry to exchange into ingots, to pay the processing fee to enter

- The cost of scrap is usually included in the cost of the product. Therefore, the sale of scrap, only income, there is no cost. If the need for management, the establishment of "raw materials - Waste - XXX" can also be. Examples are as follows:1, March 5th workshop in accordance with product production needs. Lead aluminum 1000kg, the unit price is 23.4567 yuanBorrow: production cost - direct material 23456.70Credit: raw materials, -XX profiles, 1000kg 23456.702 and March 25th, the waste generated by the workshop 20kg into the waste warehouse, according to the market price of 5 yuan /kg valuation, according to retire the library for accounting treatmentBorrowing: production costs - direct material -100Credit: raw materials - Scrap - profiles -20kg, -1003 and March 27th, the stock 1200kg scrap sent to the foundry for aluminum ingot, ingot factory price 6 yuan /kgBy: accounts receivable - foundries 7200Credit: other business income + tax 72004, March 27th, scrap exchange aluminum ingot 1050kg, unit price 8 yuan /kg, separately pay processing fee 1200 yuanBorrow: raw material - aluminium ingot 10508400Credit: accounts receivable - foundries 7200Accounts payable - foundries 1200Payment of processing fees (differentials)By: accounts payable 1200Cash: 1200

- Q: Can aluminum profiles be utilized in creating distinctive architectural structures?

- <p>Yes, aluminum profiles can be used to create unique architectural designs. They are favored for their strength, lightweight, and corrosion resistance. Architects can utilize aluminum's flexibility to design complex structures, such as intricate facades, modern window systems, and innovative support frameworks. Aluminum's adaptability allows for both functional and aesthetically pleasing designs, making it a popular choice in contemporary architecture.</p>

- Q: Are aluminum profiles suitable for use in food processing environments?

- Aluminum profiles are well-suited for application in food processing environments. The food industry widely utilizes aluminum due to its exceptional properties. Its lightweight, durable, and corrosion-resistant nature makes it an ideal material for use in food processing, where cleanliness and hygiene are paramount. Cleaning and sanitizing aluminum profiles is a breeze, which is crucial for preventing contamination and ensuring food safety. Their smooth and non-porous surface inhibits bacterial growth and simplifies maintenance. Moreover, aluminum boasts excellent thermal conductivity, enabling efficient heat transfer and temperature control during food processing. This characteristic proves particularly valuable in food packaging, cooking, and chilling applications. In addition to its physical attributes, aluminum is non-toxic and does not react with food or beverages. As an inert material, it does not release any harmful substances that could contaminate the processed food. Overall, aluminum profiles are a reliable and suitable choice for food processing environments. They meet the industry's stringent requirements for hygiene, durability, and safety, making them a popular option in the food processing and packaging sectors.

- Q: Can aluminum profiles be used for transportation applications?

- Indeed, for transportation applications, aluminum profiles are highly suitable. Due to its lightweight and durable nature, aluminum proves to be an ideal material for various transportation purposes. It is extensively employed in the fabrication of automobiles, such as cars, trucks, trains, airplanes, and ships. By utilizing aluminum profiles, robust and stiff frameworks can be constructed, ultimately decreasing the overall weight of the vehicle. Consequently, this enhances fuel efficiency and diminishes emissions. Furthermore, aluminum possesses corrosion resistance, rendering it appropriate for outdoor and maritime applications. The transportation industry widely embraces aluminum profiles due to their versatility and strength.

- Q: What are the different packaging options available for aluminum profiles?

- Aluminum profiles can be packaged in various ways to meet the specific needs and preferences of manufacturers or customers. The available packaging options include bundling, boxing, tubing, palletizing, and customized solutions. For larger profiles or bulk shipments, bundling is commonly used. This involves stacking multiple profiles together and securing them with strapping or shrink wrap. Smaller profiles can be packaged in boxes, which provide protection during transportation and storage. Individual compartments within the box prevent damage from rubbing. Circular profiles can be packaged in tubes made of durable materials like cardboard or plastic. These tubes offer excellent protection from scratches or dents. When shipping in large quantities, pallets can be used. Profiles are stacked on a pallet and secured with stretch wrap or straps. This option enables easy handling and transportation using forklifts or pallet jacks. In certain cases, customized packaging may be necessary. This can include foam inserts, protective film, or other specialized materials to ensure maximum protection during transit. When selecting the appropriate packaging option for aluminum profiles, it is important to consider factors such as size, weight, fragility, and transportation requirements. Compliance with industry standards and regulations should also be taken into account to ensure safe delivery to end-users.

- Q: Can aluminum profiles be used for solar panel mounting systems?

- Yes, aluminum profiles can be used for solar panel mounting systems. Aluminum is a commonly used material for this purpose due to its lightweight, durable, and corrosion-resistant properties. It provides a strong and stable support structure for solar panels while being easy to install and maintain.

- Q: Are aluminum profiles suitable for use in the mining industry?

- The mining industry can benefit greatly from the use of aluminum profiles. Aluminum, known for its lightweight yet strong and durable qualities, offers numerous advantages in mining applications. One crucial advantage of aluminum profiles lies in their exceptional resistance to corrosion. In the mining industry, where equipment often faces harsh environmental conditions and exposure to chemicals, this corrosion resistance is vital. Aluminum profiles can endure moisture, chemicals, and other corrosive substances without deteriorating, ensuring long-lasting performance and minimizing maintenance costs. Another perk of aluminum profiles is their impressive strength-to-weight ratio. Compared to other metals commonly used in mining equipment, such as steel, aluminum is significantly lighter. This lightweight characteristic makes aluminum profiles easier to handle, transport, and install, resulting in saved time and reduced labor costs. Despite being lightweight, aluminum profiles are still robust enough to withstand the demanding conditions of the mining industry, making them a reliable choice for various applications. Furthermore, aluminum profiles offer excellent thermal conductivity. This property proves advantageous in mining operations involving heat-generating machinery or processes. Aluminum profiles efficiently dissipate heat, preventing equipment overheating and enhancing overall safety and productivity. Moreover, aluminum is a non-magnetic material, making it ideal for mining operations that require non-magnetic equipment. This characteristic ensures that aluminum profiles will not interfere with sensitive equipment or disrupt magnetic fields, maintaining the accuracy and reliability of mining processes. In summary, aluminum profiles are highly suitable for the mining industry due to their corrosion resistance, high strength-to-weight ratio, thermal conductivity, and non-magnetic properties. Integrating aluminum profiles into mining equipment can improve performance, reduce maintenance costs, and enhance overall efficiency in various mining applications.

- Q: How can I control the hardness of 6063 aluminum profile at 6-9 degrees?

- Classification: extension material, non heat treatment alloy and heat treatment alloy1.1 non heat treated alloys: pure aluminum - 1000 series, Al Mn alloy - 3000 series, Al Si alloy - 4000 series, Al Mg alloy - 5000 Series1.2 heat treatment of Al Cu Mg alloy alloy: 2000, aluminum magnesium silicon alloy - 6000 series aluminium zinc magnesium alloy - 7000.Two, alloy number: China's current general is the American Aluminum Association "Aluminium Association" numberExamples are as follows: 1070-H14 (pure aluminum)2017-T4 (heat treatment alloy)3004-H32 (non heat treated alloy)2.1 first digit: indicates the main addition of alloying elements1: pure aluminum2: the main alloy element added copper3: the main alloying elements are manganese or manganese and magnesium4: the main alloy element is added silicon5: the main alloying element is magnesium6: mainly add alloy elements for silicon and magnesium7: the main alloying elements are zinc and magnesium8: a new alloy that does not belong to the above alloy series2.2, second digits: an alloy that indicates the addition of alloying elements or impurities in the original alloy0: table alloy1: table original alloy by the first amendment2: table original alloy after second modifications2.3, third, and four digits:Pure aluminum: represents the original alloyAlloy: the designation of individual alloys"- >: the back of Hn or Tn indicates the condition of work hardening or the symbol of heat treatment state-Hn: indicating the symbol for non heat treated alloys-Tn: a symbol for heat treatment alloysHeat treatment of 2 aluminium and aluminium alloyA chain symbol: if the alloy element is added, it is not enough to meet the requirements, but still needs cold processing, quenching and agingTreatment and soft burning to obtain the required strength and performanceAs a result of quenching and tempering, the result of quenching and tempering is chain

- Q: This question asks for a list of various aluminum profiles that are specifically designed or used for roofing systems in regions with cold climates.

- <p>In cold climates, aluminum profiles for roofing systems are selected for their durability, strength, and resistance to harsh weather conditions. Common types include: 1. Standing Seam Profiles: These are popular for their weather-tightness and resistance to snow and ice. 2. Trapezoidal Profiles: Known for their strength and ability to handle heavy snow loads. 3. Box Rib Profiles: These provide excellent structural integrity and are suitable for areas with high wind uplift. 4. Snap-Lock Profiles: Easy to install and offer good resistance to snow and ice. 5. Corrugated Profiles: Provide a traditional look while being cost-effective and offering good drainage. 6. Panel Rib Profiles: These are designed for long spans and can withstand heavy snowfall. Each profile has specific applications and advantages, and the choice depends on the specific roofing requirements and local climate conditions.</p>

- Q: Can aluminum profiles be used for creating lightweight furniture?

- Indeed, lightweight furniture can be fashioned using aluminum profiles. Given its lightweight and durable nature, aluminum proves to be an optimal choice for furniture design when weight is a factor to be taken into account. The malleability of aluminum profiles allows for their transformation into an assortment of furniture elements, including frames, legs, and supports. Moreover, the corrosion resistance offered by aluminum profiles is highly advantageous for furniture intended for outdoor or moisture-exposed environments. The adaptability of aluminum profiles enables the conception of elegant and contemporary furniture designs that not only possess a feather-light quality but also possess an aesthetically appealing allure.

Send your message to us

Extrusion Aluminum Profiles for Aluminium T-Profile Windows and Doors Installation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords