China T-One Aluminum Extrusion Profiles for Sliding Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Profile Sliding Windows and Doors Made in China

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Profile Sliding Windows and Doors Made in China

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Profile Sliding Windows and Doors Made in China

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

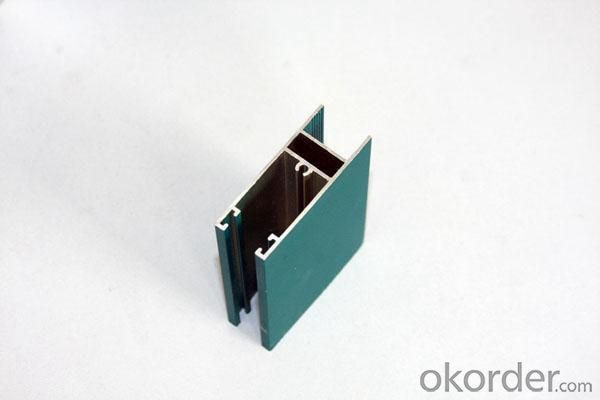

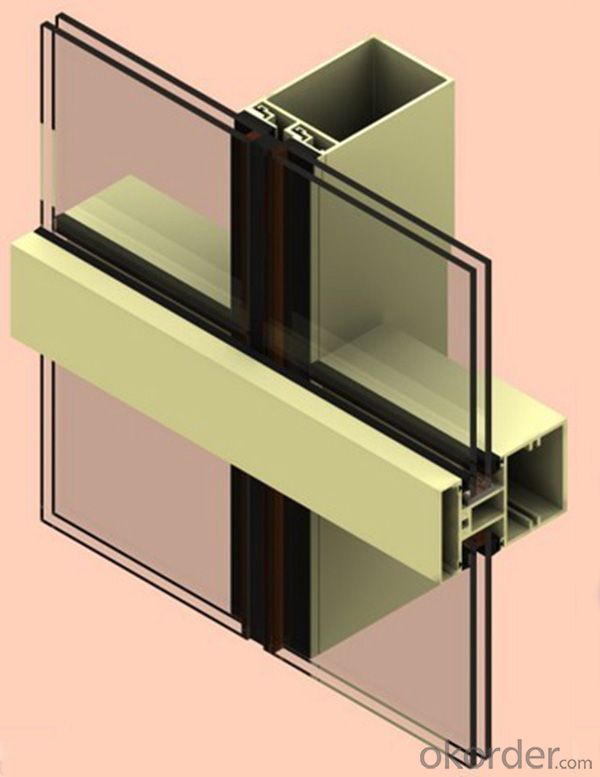

5. Image of Aluminum Profile Sliding Windows and Doors Made in China

6. Package and shipping of Aluminum Profile Sliding Windows and Doors Made in China

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: How do you install aluminum profiles?

- Follow these instructions for installing aluminum profiles: 1. Begin by measuring and cutting the profiles to the desired length using a saw equipped with a fine-tooth blade. It is essential to wear safety goggles and gloves during the cutting process. 2. Prior to installation, ensure the surface where the profiles will be placed is thoroughly cleaned. Remove any dirt, dust, or debris that could interfere with the installation. 3. Apply adhesive or silicone sealant to the back of the profile to securely attach it to the surface and create a watertight seal. 4. Position the profile on the surface and firmly press it down to guarantee proper adhesion. Utilize a level to ensure it is straight and correctly aligned. 5. If needed, utilize screws or fasteners to further secure the profile to the surface. Pre-drill pilot holes to prevent any cracking of the aluminum. 6. Repeat this process for each profile, leaving a small gap between them to account for expansion and contraction. 7. Once all profiles are installed, remove any excess adhesive or sealant. Use a damp cloth or sponge to wipe away any residue. 8. Allow the profiles to fully cure according to the manufacturer's instructions before applying any additional finishes or utilizing the area. Always consult the manufacturer's instructions for specific installation guidelines and recommendations.

- Q: Is it possible to recycle aluminum profiles and what are the benefits of doing so?

- <p>Yes, aluminum profiles can be recycled. Recycling aluminum is energy-efficient, as it requires only 5% of the energy needed to produce new aluminum from raw materials. This process reduces greenhouse gas emissions and conserves natural resources. Recycled aluminum maintains its quality, making it suitable for various applications, including construction, automotive, and consumer goods. Proper recycling also helps to reduce landfill waste and promotes a circular economy.</p>

- Q: Household aluminum profiles, which brand of cost-effective? Recommend!

- Cost performance is better, in our Nanshan factory is called a good fight,

- Q: Can aluminum profiles be used for balustrades?

- Yes, aluminum profiles can be used for balustrades. Aluminum is a lightweight and durable material that is often used in construction and architectural applications, including balustrades. It offers strength, versatility, and a sleek appearance, making it a popular choice for both residential and commercial projects. Additionally, aluminum is resistant to corrosion, which makes it suitable for outdoor installations.

- Q: Are there any specific cleaning and maintenance instructions for aluminum profiles?

- Yes, there are specific cleaning and maintenance instructions for aluminum profiles. Firstly, it is important to regularly dust and wipe down the aluminum profiles using a soft cloth or sponge. Avoid using abrasive materials or harsh chemicals, as they can damage the surface. For tougher stains or dirt, a mild soap solution can be used. It is crucial to rinse off any residue thoroughly and dry the profiles completely to prevent water spots. Additionally, applying a protective wax or polish can help maintain the shine and protect the aluminum from corrosion. Regular inspections should also be conducted to identify any signs of damage or wear, and necessary repairs should be addressed promptly.

- Q: Aluminum profiles and plastic doors and windows which good, what market?

- Do a lot of windows, Aluminum Alloy regular manufacturers are standard models of materials, thickness of 1.2 mm or more, and surface spraying or electrophoresis are very bright, the thickness of the coating is thick, make the effect and its performance are good. The insulation and heat insulation effect of the doors and windows made of plastic steel profiles and plastics are very good. Advantages: heat insulation, heat preservation, sound insulation, aging resistance, tightness: plastic door and window adopts multi-layer sealing design, and the surface of the type is smooth, and the dust and dirt are not easy to be adhered to, and the dustproof effect is excellent. Elegant and beautiful: plastic steel can be matched into a variety of colors. Plastic materials are difficult to distinguish between true and false, to verify the material capability available the most traditional way, false material is brittle, a hammer or a screwdriver on detection, especially the material edge collapse easily. Real material or carry a hammer hit several times. Because the material is recycled material, the process of adding a large amount of gypsum powder, and the surface of the material is not normal, the material is not so bright. The work is rough. Li Cunxin aluminum doors and windows. The quality and workmanship are very good. The price is still the lowest.

- Q: This question seeks to understand the methods used to prevent rust and corrosion on aluminum profiles.

- <p>To prevent aluminum profiles from rusting and corroding, several methods can be employed: 1) Anodizing: This process creates a protective oxide layer on the aluminum surface, enhancing its resistance to corrosion. 2) Powder Coating: Applying a durable powder coating can protect the aluminum from moisture and other corrosive elements. 3) Regular Cleaning: Regularly cleaning the aluminum profiles can remove dirt and debris that may lead to corrosion. 4) Protective Films: Applying protective films or tapes can shield the aluminum from environmental factors that cause corrosion. 5) Proper Storage: Storing aluminum profiles in a dry, well-ventilated area can prevent moisture accumulation, which is a leading cause of rust. 6) Use of Corrosion Inhibitors: Applying corrosion inhibitors can slow down or prevent the chemical reactions that lead to corrosion. By implementing these measures, the lifespan and integrity of aluminum profiles can be significantly improved.</p>

- Q: How much is aluminum section ton?

- Aluminum price = aluminum ingot price + processing fee + packing feeAccording to today's Yangtze River aluminum ingot price, 13350+ processing costs 3500-1200 (due to surface processing costs are not the same, floating) + packaging materials costsToday, the South China Sea informed aluminum ingot prices 13990+ processing costs, 3500-1200+ packaging materials costs, so that we can draw aluminum http://www.yzlvcai price. Mainly based on the price of aluminum ingot floating and calculate the price, so it is not a die price.

- Q: This question asks for a list of various types of adhesives that are typically used in conjunction with aluminum profiles in construction projects.

- <p>Common types of adhesives used with aluminum profiles in construction include epoxy resins, which offer strong bonding and resistance to chemicals and temperature changes; polyurethane adhesives, known for their flexibility and durability; silicone adhesives, which are excellent for sealing and bonding in a wide range of temperatures; acrylic adhesives, valued for their versatility and quick setting times; and cyanoacrylate or 'super glue', which bonds quickly and is great for small, precise applications. Each type has unique properties that make it suitable for different construction needs.</p>

- Q: Are aluminum profiles suitable for use in exterior wall systems?

- <p>Yes, aluminum profiles are commonly used for exterior wall systems due to their durability, low maintenance, and resistance to corrosion and weathering. They offer a lightweight and strong alternative to traditional materials, and can be designed to provide thermal insulation and aesthetic appeal. Their versatility allows for various configurations and customizations, making them suitable for a wide range of architectural styles and requirements.</p>

Send your message to us

China T-One Aluminum Extrusion Profiles for Sliding Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords