Aluminum Extrusion Profiles Solidworks - Extruded Aluminum Profiles Prices Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Extruded Aluminum Profiles Prices Made in China

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Extruded Aluminum Profiles Prices Made in China

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Extruded Aluminum Profiles Prices Made in China

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

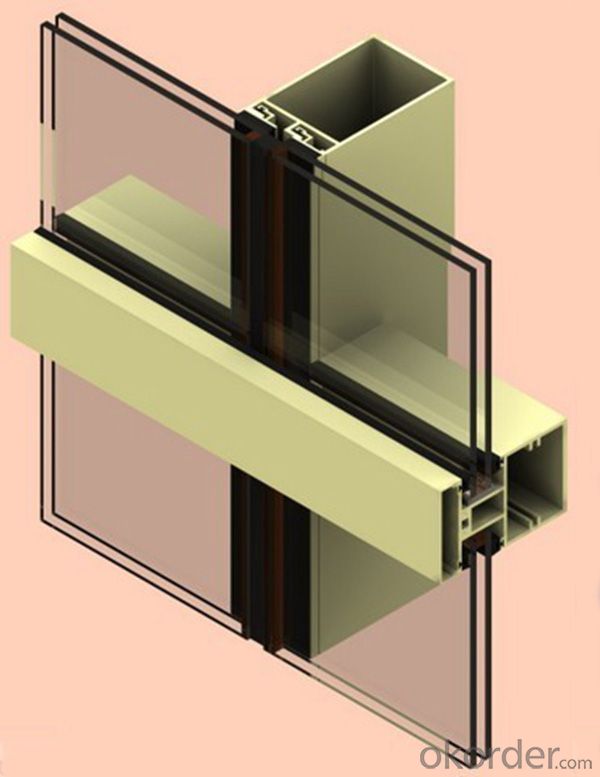

5. Image of Extruded Aluminum Profiles Prices Made in China

6. Package and shipping of Extruded Aluminum Profiles Prices Made in China

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: How do I cut and shape aluminum profiles?

- In order to cut and shape aluminum profiles, one must possess several tools and techniques. Here is a step-by-step manual to aid you in accomplishing this task: 1. Obtain the required tools: A miter saw or a circular saw equipped with a carbide-tipped blade suitable for aluminum cutting is essential. Additionally, it is advisable to possess a metal file, sandpaper, a deburring tool, and a tape measure. 2. Measure and mark: Utilize a tape measure to determine the desired length of the aluminum profile. Indicate the location where the cut is to be made using a pencil or marker. 3. Secure the aluminum: Firmly place the aluminum profile on a workbench or cutting surface. Utilize clamps or a vice to hold it securely in place, ensuring it remains stationary during the cutting process. 4. Cut the aluminum: Position the saw blade at the marked location and align it perpendicular to the aluminum profile. Initiate the saw and gradually guide it through the aluminum, applying constant pressure. Allow the saw to perform the task without exerting excessive force, as excessive pressure may cause the blade to bind or chip. Exercise caution and wear safety goggles and gloves to shield yourself from any flying debris. 5. Smooth the edges: Following the cut, you may observe sharp or rough edges on the aluminum profile. Employ a metal file or sandpaper to level these edges, ensuring a clean and safe outcome. 6. Deburring: Employ a deburring tool to eliminate any burrs or rough spots remaining from the cutting process. Gently run the tool along the cut edges, applying slight pressure to smoothen them. 7. Shape the aluminum: If shaping the aluminum profile is necessary, numerous methods can be employed. A common technique involves clamping the profile to a workbench and gradually bending it using a hammer or rubber mallet. Alternatively, specialized tools such as a metal brake or bending machine can be utilized for more precise shaping. 8. Final touches: Once the aluminum profile has been cut and shaped, thoroughly clean it to eliminate any debris or metal shavings. Inspect the profile for any imperfections and make necessary adjustments before employing it for the intended application. Remember to exercise proper safety precautions throughout the process, including wearing safety goggles, gloves, and securely fastening the aluminum profile to prevent accidents.

- Q: You need is the extrusion machine section now has Liaoning Zhong Wang Liaoyuan Midas Nanshan aluminum aluminum Hunan Sheng Guangxi jungle SWA South northeast light alloy etc. they have more than 4500 tons of extrusion machine mainly produces large section comprises a track body profile LED lamp shell container ship with large cross section conductor rail section I is a seamless tube a market analyst if you have aluminum industrial material need to be aware of the problem you can consult me as friends.

- 4500T is not very large extrusion machine, a little aluminum factory are generally, in the hope of Liaoning, Qinghai Guoxin, Yun ore has more than 10000 tons of production lines, more than sixty percent domestic aluminum production is Guangdong Foshan, there are several manufacturers have the production line, such as Albert, Jianmei so, need to understand the aluminum things to find the best side to understand

- Q: What are the vibration damping properties of aluminum profiles?

- Aluminum profiles boast outstanding capabilities in mitigating vibrations. With their impressive ratio of stiffness to mass, aluminum profiles efficiently absorb and disperse vibrations, resulting in decreased magnitude and prevention of transmission to nearby structures. This particular attribute renders aluminum profiles highly suitable for industries like aerospace, automotive, and construction, where vibration management is of utmost importance. The inherent damping properties of aluminum profiles aid in reducing noise, minimizing damage, and guaranteeing structural stability. Moreover, aluminum's capacity to damp vibrations further elevates the overall comfort and safety of diverse products and structures.

- Q: What are the different surface polishing options for aluminum profiles?

- There are several surface polishing options for aluminum profiles, including mechanical polishing, chemical polishing, electro-polishing, and anodizing. Mechanical polishing involves the use of abrasive materials to remove imperfections and create a smooth surface. Chemical polishing uses chemical solutions to dissolve a thin layer of aluminum and produce a polished finish. Electro-polishing uses an electric current to remove surface imperfections and create a shiny surface. Anodizing is a process in which a protective oxide layer is formed on the surface of the aluminum, providing both a polished appearance and enhanced corrosion resistance.

- Q: This question asks for a method to determine the quantity of aluminum profiles required for a construction project.

- <p>To calculate the amount of aluminum profiles needed for a building project, follow these steps: 1. Determine the design specifications and dimensions of the project, including the length, width, and height of the structure. 2. Identify the types and sizes of aluminum profiles required based on the structural needs and design. 3. Calculate the total linear footage of each profile type needed by multiplying the length of each required section by the number of sections. 4. Add up the total linear footage for all profile types. 5. Account for waste and cutting losses, typically adding 5-10% to the total. 6. Ensure the calculations comply with building codes and safety standards. Consult with engineers or architects if necessary.</p>

- Q: Can aluminum profiles be used in the manufacturing of furniture?

- Furniture production can utilize aluminum profiles, which are versatile and lightweight materials. Aluminum possesses numerous advantages for furniture manufacturing, such as durability, corrosion resistance, and a high strength-to-weight ratio. Due to these properties, it is suitable for various furniture applications, including chairs, tables, shelving units, and frames. Moreover, aluminum profiles offer easy customization, enabling the creation of distinctive and contemporary designs. By incorporating aluminum into furniture manufacturing, sustainability is promoted as it is a recyclable material. In conclusion, aluminum profiles offer flexibility and durability to designers and manufacturers, rendering them a favored option in the furniture industry.

- Q: How is the thickness of the base plate of the aluminum profile radiator calculated? Are there formulas for calculation?

- There should be empirical formula, the heat of the surface heat dissipation is related to thermal conductivity, thickness, temperature change, surface area. Then the best thickness is calculated by linear programming.

- Q: This question asks for a list of various types of adhesives that are typically used in conjunction with aluminum profiles in construction projects.

- <p>Common types of adhesives used with aluminum profiles in construction include epoxy resins, which offer strong bonding and resistance to chemicals and temperature changes; polyurethane adhesives, known for their flexibility and durability; silicone adhesives, which are excellent for sealing and bonding in a wide range of temperatures; acrylic adhesives, valued for their versatility and quick setting times; and cyanoacrylate or 'super glue', which bonds quickly and is great for small, precise applications. Each type has unique properties that make it suitable for different construction needs.</p>

- Q: For example, 80*80 square tube 2.0mm thick. Or 38*25 square tube, 0.8mm thick, how to calculate the rice weight? Please tell the specific formula, urgent

- Length (you want to count the number of meters) * width (square tube expansion size) * high (wall thickness) * density (you this square tube material density, aluminum alloy gold density is more complex, generally in 2650~2750Kg/m3)1m * (0.08 * 4) * * 2750kg/m 0.002=0.00064m fand fand =1.76KGThen you 80*80 wall thickness of 2 square tubes, one meter is 1.76 kilogramsWindows and doors exchange group (228021644) hope to help you!

- Q: Are aluminum profiles suitable for use in the construction of high-rise buildings?

- <p>Yes, aluminum profiles can be used in high-rise buildings. They are known for their high strength-to-weight ratio, which makes them ideal for structural applications where weight is a concern. Aluminum profiles are also resistant to corrosion and can withstand harsh weather conditions, making them a popular choice for exterior applications. Additionally, their recyclability and sustainability make them an environmentally friendly option. However, it's important to ensure that the aluminum profiles meet the specific load-bearing requirements and safety standards for high-rise construction.</p>

Send your message to us

Aluminum Extrusion Profiles Solidworks - Extruded Aluminum Profiles Prices Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords