Extruded Aluminum Profiles China - Aluminum Perfiles Extruidos Producidos

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Perfiles Extruidos Producidos Made in China

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Perfiles Extruidos Producidos Made in China

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Perfiles Extruidos Producidos Made in China

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

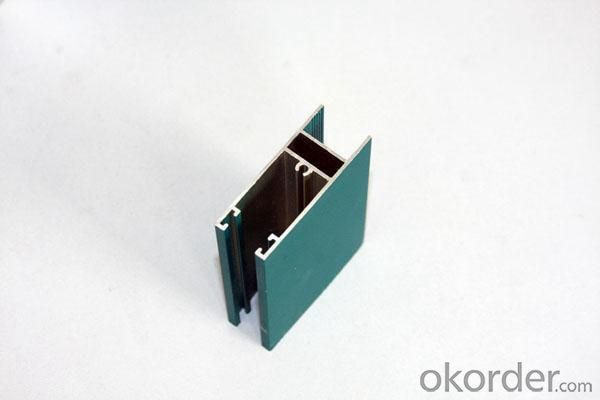

5. Image of

6. Package and shipping of Aluminum Perfiles Extruidos Producidos Made in China

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Are aluminum profiles suitable for use in pharmaceutical manufacturing?

- Yes, aluminum profiles are suitable for use in pharmaceutical manufacturing. They are lightweight, corrosion-resistant, and easily sanitized, making them ideal for maintaining high levels of cleanliness and meeting the stringent requirements of pharmaceutical manufacturing processes. Additionally, aluminum profiles offer excellent strength and durability, ensuring the safety and reliability of pharmaceutical equipment.

- Q: What are the various types of connectors that can be used with aluminum profiles?

- <p>Aluminum profiles can be connected using a variety of connectors designed for different applications and structural needs. Common types include: 1. T-slots connectors, which slide into the T-slots of the profiles for secure attachment. 2. Angle connectors, used to join profiles at right angles. 3. Corner brackets, for creating 90-degree corners. 4. Clamping blocks, which hold profiles together without screws. 5. Hinges, allowing for pivoting movements. 6. End caps, to cover the ends of profiles. 7. Cylindrical connectors, for joining round tubes. 8. Linear connectors, for straight-line connections. 9. Specialized connectors for specific applications, such as cable management or mounting brackets. These connectors are crucial for assembling aluminum profile systems in various configurations.</p>

- Q: What are the different cutting options available for aluminum profiles?

- Aluminum profiles have various cutting options to choose from, depending on the project's specific requirements. Some commonly used cutting methods include: 1. Miter Saw: A popular choice for aluminum profiles, the miter saw utilizes a circular blade to make precise angled cuts, ensuring accuracy and cleanliness. 2. Chop Saw: Similar to the miter saw, the chop saw is also frequently employed for cutting aluminum profiles. It effortlessly creates straight cuts at 90-degree angles, making it efficient and capable of handling larger profiles. 3. Bandsaw: Offering versatility, the bandsaw utilizes a continuous looped blade to make straight cuts. It provides flexibility in terms of cutting angles and can handle thicker aluminum profiles. 4. CNC Cutting: Renowned for its precision, CNC cutting involves the use of a computer-controlled cutting machine that can follow intricate design patterns. This method is ideal for detailed and intricate cuts, guaranteeing high precision and repeatability. 5. Laser Cutting: Laser cutting is a popular choice due to its high precision and ability to create clean cuts. By using a focused laser beam to melt or vaporize the aluminum, laser cutting ensures smooth and accurate results. It is suitable for both simple and complex designs. 6. Waterjet Cutting: Waterjet cutting is a versatile method that employs a high-pressure jet of water mixed with abrasive particles to cut through aluminum profiles. It can handle various thicknesses and shapes, providing precise cuts without altering the properties of the aluminum or generating heat. 7. Shearing: A basic yet effective cutting method, shearing involves using sharp blades to trim or cut aluminum profiles. It is commonly used for straight cuts and is suitable for thinner profiles. 8. Plasma Cutting: Plasma cutting employs a high-velocity jet of ionized gas to cut through aluminum profiles. It is suitable for thicker profiles and allows for faster cutting speeds compared to other methods. These are just a few of the cutting options available for aluminum profiles. The choice of method depends on factors such as desired cut type, accuracy requirements, profile thickness, and design complexity. It is crucial to consider these factors and seek professional consultation to determine the most suitable cutting option for a specific project.

- Q: This question asks for an explanation of the various methods employed in the manufacturing of aluminum profiles.

- <p>Aluminum profiles are produced using several manufacturing processes, each suited to different applications and profile shapes. The primary methods include: Casting, where molten aluminum is poured into molds to form profiles; Extrusion, the most common process, where aluminum is pushed through a die to create long, continuous shapes; Rolling, used for creating flat or curved sheets and plates; Forging, which involves shaping aluminum by applying compressive forces; and Machining, where aluminum profiles are cut and shaped using tools. Each process has its advantages and is chosen based on the desired profile's complexity, strength, and cost-effectiveness.</p>

- Q: Can aluminum profiles be used for stadium seating?

- Yes, aluminum profiles can be used for stadium seating. Aluminum is a lightweight and durable material that is commonly used in various construction applications, including stadium seating. It offers the advantage of being corrosion-resistant, easy to maintain, and can be customized to meet specific design requirements. Additionally, aluminum profiles provide structural stability and can withstand heavy loads, making them suitable for stadium seating systems.

- Q: What are the potential health risks associated with handling aluminum profiles?

- <p>Working with aluminum profiles generally does not pose significant health concerns under normal conditions. However, there are a few considerations. Inhalation of aluminum dust can cause respiratory issues, and prolonged exposure may lead to a condition known as 'aluminum dust disease.' Additionally, aluminum can cause skin irritation in some individuals, especially with prolonged contact. It's important to use proper personal protective equipment (PPE), such as masks and gloves, to minimize these risks. Ingestion of aluminum is also a concern, as it can lead to health problems if it enters the body through contaminated food or water, although this is not directly related to handling aluminum profiles.</p>

- Q: How are aluminum shapes made?

- 2, extrusion: extrusion is the method of forming profiles. Firstly, the die is designed and manufactured according to the section of the profile, and the heated round casting bar is extruded out of the die by using an extruder. Commonly used grade 6063 alloy, in the extrusion, also use an air-cooled quenching process and the artificial aging process, to complete the heat treatment strengthening. Different grades of alloy can be treated by heat treatment, and their heat treatment system is different.

- Q: This question asks about the various applications of aluminum profiles within the construction industry.

- <p>Aluminum profiles are versatile in construction and have several uses: 1. Structural framing for buildings, providing support and stability. 2. Window and door frames, known for their durability and resistance to corrosion. 3. Facade systems, offering lightweight and aesthetically pleasing exterior solutions. 4. Modular construction, where aluminum profiles can be prefabricated and assembled quickly. 5. Roofing and cladding systems, due to their weather resistance and ease of installation. 6. Handrails and balustrades for safety and design. 7. Solar panel mounting structures, taking advantage of aluminum's lightweight and strength. 8. Scaffolding systems, for temporary construction support. These applications highlight aluminum's adaptability and strength in construction.</p>

- Q: This question is asking about the various types of aluminum profiles that are used for exterior cladding purposes.

- <p>Aluminum profiles for exterior cladding are diverse and serve various architectural and functional needs. Some common types include: 1. Flat Profiles: Used for simple, sleek designs. 2. Box Profiles: Ideal for creating a modern, industrial look. 3. Angle Profiles: Useful for corners and edges. 4. Channel Profiles: Often used for window and door frames. 5. T-Profiles: Commonly used for hidden fastening systems. 6. U-Channels: Suitable for cover applications. 7. Special Profiles: Custom designs for specific architectural requirements. Each type offers unique benefits in terms of aesthetics, strength, and weather resistance, making them suitable for different building facades and exterior applications.</p>

- Q: Are aluminum profiles capable of being tailored to fulfill unique design needs or standards?

- <p>Yes, aluminum profiles can be customized to meet specific design requirements or specifications. This customization can include varying the dimensions, finishes, and shapes to fit the intended application. Manufacturers can modify the extrusion process to create profiles with specific tolerances, surface treatments, and mechanical properties. This flexibility makes aluminum profiles suitable for a wide range of industries, including construction, automotive, and aerospace.</p>

Send your message to us

Extruded Aluminum Profiles China - Aluminum Perfiles Extruidos Producidos

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords