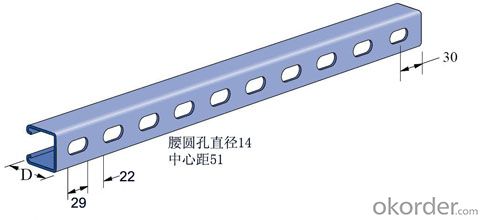

equilateral H type steel, galvanized Z type steel, solar stent type Z steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 8000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Design and construction of atlas and complete, all the stress components -- type steel and fastener (with locking serrations) can realize the assembly components of a rigid mating,connecting without displacement, no order adjustment, accurate positioning. Shock and vibration, enhance the shear resistance capacity of bracket nodes.

And tracking services, real-time guidance, doubts on the construction site

Technical personnel at the scene guidance, FAQ, do mechanics analysis in real-time tomeet in the construction of the special support and hanger, and the coordination of various professional bundle

And fast installation, short construction period

The installation speed is 6~8 times of traditional practices, in reducing the cost ofmanufacture and installation of 1/2. All professions and trades cross operation, improve work efficiency, shorten the construction period.

And long service life, convenient maintenance

The use of the environment, according to special requirements of customers, provide different process materials are electric galvanized (Leng Duxin), hot dip galvanized andgalvanized coating powder (spray)

Quasi - materials budget

Ensure the products for the standardization of semi-finished products, model identificationwith clear, standardized management, materials and the fittings on the waste and loss ofrare.

And excellent quality assurance

With ISO9000, ISO9002 standard, ensure the stability of the whole system integrity andhanger.

Good generality

And the combination of standard component types of rich, available options. Ensure all kinds of support under different conditions, simplicity, applicability and flexibility.

And environmental protection

Construction without welding and flame, will not impact on the environment and office.

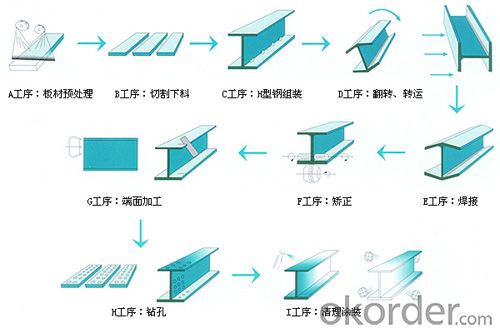

Our factory has ten fully automatic and semi automatic cold bending production line eight,has its own development team, the independent development of mold design to meet the various needs of customers. Product appearance, size precision, reasonable design,convenient use saves the massive manpower and physical for customers, reducing the cost, the products are widely used in the construction industry, automobile manufacturing,solar power generation, machinery manufacturing, power transmission tower, bridge, shipmilitary aviation industry, railway and highway construction, machine room

- Q: What is the role of steel in insulation and energy efficiency?

- Steel does not directly contribute to insulation and energy efficiency. However, it is commonly used in the construction of energy-efficient buildings due to its strength and durability, which allows for the creation of well-insulated structures. Steel is often incorporated into the framework of buildings, providing stability and support for insulation materials, such as foam or fiberglass, which are responsible for the actual insulation and energy efficiency.

- Q: What are the different types of steel structures?

- Some of the different types of steel structures include steel frame structures, steel truss structures, steel arch structures, steel grid structures, and steel shell structures.

- Q: How are steel structures designed for long spans and open spaces?

- Steel structures are designed for long spans and open spaces by taking advantage of the material's unique properties and utilizing efficient structural systems. Firstly, steel is known for its high strength-to-weight ratio, which allows for the construction of lightweight structures that can span large distances. This property enables the design of long-span steel structures that can cover vast areas without the need for intermediate columns or supports. To achieve this, engineers employ different structural systems such as trusses, arches, and cable-supported structures. Trusses are commonly used for long-span steel structures as they efficiently distribute the loads across multiple members, reducing the need for bulky columns or walls. Arches provide natural structural stability, allowing for long spans with minimal internal supports. Cable-supported structures, such as suspension bridges, use high-strength steel cables to support the weight of the structure, allowing for even longer spans. Another important factor in designing steel structures for long spans and open spaces is the use of computer-aided design (CAD) and advanced analysis software. These tools help engineers accurately analyze the structural behavior and optimize the design for maximum efficiency. By simulating different loading conditions and testing various design options, engineers can identify the most suitable structural system and select the appropriate steel sections to achieve the desired span and open space. Moreover, steel structures can be prefabricated off-site, allowing for faster construction and minimizing disruption to the surrounding area. This prefabrication process ensures high precision and quality control, resulting in efficient and reliable structures. Overall, steel structures are designed for long spans and open spaces by leveraging the material's inherent strength, utilizing efficient structural systems, employing advanced analysis tools, and implementing prefabrication techniques. These factors combine to create versatile, cost-effective, and aesthetically pleasing solutions for a wide range of applications, including warehouses, sports arenas, exhibition halls, and airports.

- Q: How are steel structures designed to accommodate fire protection systems?

- Steel structures are designed to accommodate fire protection systems by incorporating features such as fire-resistant coatings, fireproofing materials, and the inclusion of fire barriers and compartments. These measures help to prevent or slow down the spread of fire, allowing occupants more time to evacuate and firefighters more time to respond. Additionally, fire alarm systems, sprinkler systems, and smoke control systems are integrated into the design to detect and suppress fires effectively.

- Q: How are steel structures used in research and laboratory buildings?

- Steel structures are widely used in research and laboratory buildings due to their numerous advantages. Firstly, steel is known for its strength and durability, making it an ideal material for supporting heavy scientific equipment and machinery. This allows for the construction of large open spaces without the need for excessive columns or walls, providing flexibility for future modifications or reconfigurations of the building layout. Additionally, steel structures offer a high level of precision and accuracy, which is crucial in research and laboratory settings. The dimensional stability of steel ensures that measurements and experiments are not affected by structural deformations over time. This is especially important in environments where sensitive instruments and equipment are used, as even the slightest movement or vibration can compromise the accuracy of results. Steel also possesses excellent fire resistance properties, which is essential for laboratory buildings where hazardous materials are handled. Steel structures can be designed to meet specific fire resistance requirements, ensuring the safety of researchers and preventing the spread of fire in case of an accident or malfunction. Moreover, steel structures are relatively lightweight compared to other construction materials, allowing for faster and more efficient construction processes. This is particularly advantageous for research and laboratory buildings where time is a critical factor in project completion. The use of steel also reduces the need for extensive foundations, resulting in cost savings and less disruption to the surrounding environment. In terms of sustainability, steel structures are highly recyclable and can be reused or repurposed after their useful life, minimizing waste and reducing the environmental impact. Steel also has a lower carbon footprint compared to other materials commonly used in construction, making it a more sustainable choice for research and laboratory buildings. Overall, the use of steel structures in research and laboratory buildings offers numerous benefits, including strength, durability, precision, fire resistance, efficiency, and sustainability. These advantages make steel a preferred choice for creating safe, adaptable, and functional spaces that meet the unique requirements of research and laboratory facilities.

- Q: What is the role of steel in sports facilities?

- Due to its strength, durability, and versatility, steel plays a vital role in the construction of sports facilities. When it comes to sports, steel is primarily used for structural framing, creating a stable and secure environment for athletes and spectators alike. One of the main advantages of steel in sports facilities is its high strength-to-weight ratio. This allows for the creation of spacious areas without the need for excessive supporting columns or walls. Architects and engineers can design stadiums and arenas with unobstructed views and roomy interiors, enhancing the overall experience for spectators. Steel is also renowned for its durability, making it ideal for withstanding the demanding conditions of sports facilities. Whether it's the heavy loads exerted by large crowds or the potential impact from sporting activities, steel provides the necessary strength and resilience to maintain the structural integrity of the facility. Furthermore, steel's versatility allows for flexible design options, enabling the construction of unique and iconic sports venues. The material can be easily shaped, allowing for the construction of curved or sloping structures, as well as the incorporation of complex architectural features. This versatility not only adds aesthetic appeal but also contributes to the functionality and performance of the facility. In addition to its structural role, steel is extensively used in the infrastructure of sports facilities. This includes the construction of roofs, grandstands, staircases, walkways, and even the installation of lighting systems. Steel's versatility and ease of installation make it the preferred choice for these components, ensuring both safety and functionality. Overall, steel's role in sports facilities is essential. Its strength, durability, and versatility contribute to the construction of safe and visually pleasing venues that can accommodate large crowds, withstand the demands of sporting events, and provide an enjoyable experience for athletes and spectators.

- Q: How are steel structures used in the construction of stadiums?

- Steel structures are commonly used in the construction of stadiums due to their strength, durability, and versatility. Steel beams and columns provide the necessary support for large spans, allowing for the creation of expansive open spaces within stadiums. Additionally, steel is lightweight, making it easier to transport and assemble on-site. This material is also resistant to fire, corrosion, and seismic activities, ensuring long-lasting and safe structures. From the framework to the roof and seating areas, steel is utilized in various aspects of stadium construction, enabling the creation of iconic and iconic sports venues worldwide.

- Q: Can steel structures be designed with pedestrian bridges?

- Yes, steel structures can indeed be designed and used for pedestrian bridges. Steel offers several advantages for bridge construction, such as its high strength-to-weight ratio, durability, and ability to span long distances. Steel bridges can be designed to accommodate pedestrian traffic by incorporating appropriate safety features like guardrails, non-slip surfaces, and adequate width for pedestrians to walk comfortably.

- Q: What are the challenges associated with erecting steel structures?

- There are several challenges associated with erecting steel structures. One of the main challenges is the complexity of the construction process. Steel structures often require meticulous planning and coordination to ensure that all components are properly aligned and connected. This involves careful consideration of the structural design, fabrication, transportation, and installation. Another challenge is the weight and size of steel components. Steel structures can be extremely heavy, and transporting and lifting these components can be difficult and require specialized equipment. The size of these components can also pose logistical challenges, especially when working in confined spaces or urban environments. Furthermore, safety is a major concern when erecting steel structures. Workers must adhere to strict safety protocols to prevent accidents and injuries. This includes proper training in using heavy machinery, ensuring proper fall protection, and following safety guidelines during installation. Weather conditions can also present challenges during the erection process. Wind, rain, and extreme temperatures can affect the stability of the structure and pose risks to workers. Therefore, construction schedules must be carefully planned to minimize exposure to adverse weather conditions. Additionally, the cost of erecting steel structures can be a challenge. The materials and equipment required for steel construction can be expensive, and the labor costs associated with skilled workers can also be high. Therefore, careful budgeting and cost management are necessary to ensure the project remains within the allocated financial resources. Overall, erecting steel structures requires careful planning, coordination, and consideration of various challenges. However, with proper preparation and experienced professionals, these challenges can be overcome to successfully complete construction projects.

- Q: What are the design considerations for steel mixed-use buildings?

- Design considerations for steel mixed-use buildings include structural integrity, flexibility, fire safety, acoustic performance, and sustainability. Firstly, structural integrity is a key consideration when designing steel mixed-use buildings. Steel is known for its strength and durability, making it an ideal material for supporting complex and multi-story structures. The design must account for the loads and stresses that the building will experience, ensuring that the steel framework can safely support the various uses and occupancies within the building. Flexibility is another important factor in the design of steel mixed-use buildings. These buildings often house a combination of residential, commercial, and recreational spaces, which may have different spatial requirements. Steel offers the advantage of long-span capabilities, allowing for open floor plans and adaptable spaces that can be easily reconfigured as the needs of the occupants change over time. Fire safety is a critical consideration in any building design, and steel provides inherent fire-resistant properties. However, the design must also include measures to prevent fire spread, such as fire-rated partitions, adequate fire exits, and effective fire suppression systems. Additionally, the design should incorporate fire-resistant materials for finishes and furnishings to enhance the overall fire safety of the building. Acoustic performance is another important consideration, especially in mixed-use buildings where different activities and uses may generate varying levels of noise. The design should include appropriate sound insulation measures to minimize sound transmission between different spaces and ensure a comfortable and peaceful environment for occupants. Finally, sustainability is an increasingly important consideration in building design. Steel is a highly recyclable material, and its use in construction can contribute to reducing the environmental impact of the building. The design should consider energy efficiency measures, such as incorporating natural lighting and ventilation, as well as integrating renewable energy sources. Additionally, the selection of sustainable materials and the incorporation of green building practices can further enhance the sustainability of steel mixed-use buildings. In summary, the design considerations for steel mixed-use buildings encompass structural integrity, flexibility, fire safety, acoustic performance, and sustainability. By addressing these aspects, architects and engineers can create buildings that are not only aesthetically pleasing but also safe, functional, and environmentally responsible.

Send your message to us

equilateral H type steel, galvanized Z type steel, solar stent type Z steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 8000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords