EPDM Waterproofing Rubber Roofing Membrane New Kind

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

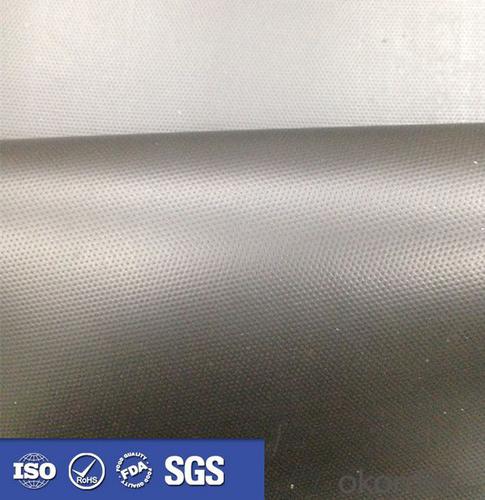

Description Of EPDM Waterproofing Rubber Roofing Membrane New Kind:

Self adhesive waterproof rolling material:

thickness:1.2/1.5/2.0mm

length/roll:10/20m

width/roll:1.02m

Low temperature:-15 -20,-30

Main Features of EPDM Waterproofing Rubber Roofing Membrane New Kind:

1) High tear

2) High puncturing strength

3) Great temperature resistance.

4) High dimensional stability

Specifications of EPDM Waterproofing Rubber Roofing Membrane New Kind:

Material | EPDM Self-adhesive Waterproof Membrane |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Waterproofing Rubber Roofing Membrane New Kind:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Does a waterproofing membrane require any specific safety precautions during installation?

- Yes, installing a waterproofing membrane does require specific safety precautions. These may include wearing protective clothing, such as gloves and goggles, to prevent contact with chemicals or materials that may be harmful. It is important to ensure proper ventilation in the installation area to minimize exposure to potentially harmful fumes or vapors. Additionally, following manufacturer's instructions, using proper tools and equipment, and working in a well-organized manner can help prevent accidents or injuries during the installation process.

- Q: Are waterproofing membranes resistant to freeze-thaw cycles?

- Waterproofing membranes, in general, exhibit resistance towards freeze-thaw cycles. Their design caters to enduring severe weather patterns, which encompass freezing temperatures and subsequent thawing. The selection of materials for these membranes is often based on their durability and capacity to expand and contract without jeopardizing their waterproofing capabilities. This resilience against freeze-thaw cycles guarantees the preservation of membrane integrity and efficacy in obstructing water infiltration, irrespective of regions experiencing frequent temperature fluctuations.

- Q: Can a waterproofing membrane be applied to roofing systems?

- Yes, a waterproofing membrane can be applied to roofing systems. Waterproofing membranes are commonly used in roofing to provide an additional layer of protection against water and moisture infiltration. These membranes are typically made of synthetic materials such as PVC or EPDM and are designed to be durable, flexible, and resistant to environmental factors such as UV radiation and temperature fluctuations. When properly installed, a waterproofing membrane can help to prevent leaks, extend the lifespan of the roof, and protect the underlying structure from water damage. It is important to consult with a professional roofing contractor to determine the most suitable type of waterproofing membrane for a specific roofing system and to ensure proper installation and maintenance.

- Q: Can a waterproofing membrane be used for wastewater treatment plants or sewage facilities?

- Yes, a waterproofing membrane can be used for wastewater treatment plants or sewage facilities. It helps to prevent water leakage, ensuring the containment and proper treatment of wastewater or sewage.

- Q: Can a waterproofing membrane be used for basements?

- Yes, a waterproofing membrane can be used for basements. Waterproofing membranes are commonly used in basements to prevent water penetration and protect the interior space from moisture damage.

- Q: Can a waterproofing membrane be used for walkways or pedestrian bridges?

- Yes, a waterproofing membrane can be used for walkways or pedestrian bridges. Waterproofing membranes are designed to create a barrier that prevents water from seeping into the structure and causing damage. By applying a waterproofing membrane to the surface of a walkway or pedestrian bridge, it can protect the underlying structure from water infiltration, thus increasing its durability and lifespan. This is especially important in areas prone to heavy rainfall or where the walkway or bridge is exposed to water sources such as rivers or lakes. Additionally, waterproofing membranes can also provide additional benefits such as improving slip resistance and protecting against chemicals or pollutants.

- Q: Can waterproofing membranes be used on below-grade parking structures?

- Yes, waterproofing membranes can be used on below-grade parking structures. In fact, they are commonly used to protect these structures from water infiltration and potential damage. Waterproofing membranes are designed to provide a barrier against water penetration, thus preventing moisture from seeping into the concrete and causing deterioration. These membranes can be applied to the below-grade walls and floors of parking structures to ensure their long-term durability and structural integrity. Additionally, waterproofing membranes can also help prevent the formation of mold and mildew, which can be a common issue in damp environments such as below-grade parking structures. Overall, using waterproofing membranes is highly recommended for below-grade parking structures to protect them from water damage and extend their lifespan.

- Q: Can a waterproofing membrane be used in crawl spaces?

- Yes, a waterproofing membrane can be used in crawl spaces to prevent moisture infiltration and protect the space from water damage.

- Q: Can a waterproofing membrane be used for a sports facility?

- Yes, a waterproofing membrane can be used for a sports facility. Waterproofing membranes are commonly used to protect buildings and structures from water damage, including sports facilities. They can be applied to various surfaces such as roofs, walls, and floors to prevent water infiltration and ensure a dry and safe environment for athletes and spectators.

- Q: SBS waterproofing membrane sub-class I and II when to use what level to use a secondary level

- Classification: According to physical indicators are divided into: Ⅰ (-20 ℃), Ⅱ (-25 ℃) type two categories; According to the fetal base can be divided into: polyester tires, glass fiber tire two categories; according to the surface material can be divided Waterproof sheet

Send your message to us

EPDM Waterproofing Rubber Roofing Membrane New Kind

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords