EPDM Waterproof Rubber Membrane with 2.0mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

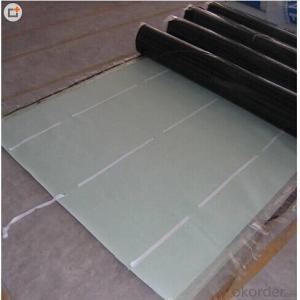

EPDM Waterproof Rubber Membrane with 2.0mm Thickness

Description Of EPDM Waterproof Rubber Membrane with 2.0mm Thickness:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Waterproof Rubber Membrane with 2.0mm Thickness:

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Specifications of EPDM Waterproof Rubber Membrane with 2.0mm Thickness:

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strenght,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

Applications of EPDM Waterproof Rubber Membrane with 2.0mm Thickness:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

IMages of EPDM Waterproof Rubber Membrane with 2.0mm Thickness:

<img alt="wKhQpFVgNGGEHhlqAAAAAOq8DWg838_gezshou.jpg" src="https://file2.okorder.com/attach/2015/07/06/36ad99a316c05c4eb552ce97f8d3bd30.jpg" style="float: none; w

- Q: Can a waterproofing membrane be used for a dam?

- Yes, a waterproofing membrane can be used for a dam. It can effectively prevent water leakage and seepage, ensuring the structural integrity of the dam and its ability to hold and control water.

- Q: Does a waterproofing membrane require any specific surface preparation?

- Specific surface preparation is necessary prior to the installation of a waterproofing membrane. The quality and condition of the surface play a significant role in determining the success and effectiveness of the membrane. To begin with, the surface must be thoroughly cleaned and devoid of any dirt, debris, oil, grease, or loose particles. This can be accomplished by utilizing a pressure washer, scrub brush, or appropriate cleaning agents. Additionally, any existing coatings or sealants must be eliminated to ensure proper adhesion of the membrane. Furthermore, the surface should be even and smooth. Any uneven areas, cracks, or holes need to be repaired and leveled prior to applying the membrane. This can be achieved by filling the cracks or holes with a suitable filler or patching compound and smoothing it out to establish a uniform surface. Moreover, it is imperative that the surface is completely dry. Moisture can compromise the adhesion and effectiveness of the waterproofing membrane. Therefore, it is essential to ensure the surface is fully dry before commencing the installation. This may involve allowing the surface to air dry or employing appropriate drying methods such as fans or dehumidifiers. In addition to these general surface preparations, specific types of waterproofing membranes may entail additional requirements. For instance, certain membranes may necessitate the application of a primer on the surface before installation. It is crucial to adhere to the manufacturer's instructions and recommendations for the specific membrane being used. Overall, proper surface preparation is vital for the accomplishment of a waterproofing membrane installation. It guarantees optimal adhesion, durability, and performance of the membrane, ultimately preventing water penetration and safeguarding the underlying structure.

- Q: Can a waterproofing membrane be applied on a vertical surface?

- Yes, a waterproofing membrane can be applied on a vertical surface. Waterproofing membranes are designed to create a barrier against water penetration, whether it is applied horizontally or vertically. They are commonly used on vertical surfaces such as walls, retaining walls, and foundations to prevent water damage and leakage.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Yes, a waterproofing membrane can be used on adobe block surfaces. Adobe blocks are made from a mixture of clay, sand, and straw, which can be susceptible to water damage. Applying a waterproofing membrane can help prevent water penetration and protect the adobe blocks from moisture-related issues such as cracking, erosion, or mold growth. It is important to ensure that the waterproofing membrane is compatible with adobe surfaces and follows the manufacturer's guidelines for application. Additionally, proper surface preparation and repair of any existing damage is crucial before applying the membrane to ensure its effectiveness.

- Q: Can a waterproofing membrane be used for tunnels and underground structures?

- Yes, a waterproofing membrane can be used for tunnels and underground structures. Waterproofing membranes are commonly used in construction to provide a barrier against water infiltration and protect structures from potential damage caused by water. In the case of tunnels and underground structures, where there is a higher risk of water ingress due to the surrounding soil and groundwater, waterproofing membranes are essential to ensure the integrity and longevity of the infrastructure. Waterproofing membranes for tunnels and underground structures are specifically designed to withstand the unique challenges posed by these environments. They are typically made of durable and flexible materials such as bitumen, PVC, or EPDM, which can effectively resist water pressure and provide long-lasting protection. Additionally, these membranes are often reinforced with various layers or fabrics to enhance their strength and resistance to puncture or tear. The application of waterproofing membranes in tunnels and underground structures involves a meticulous process. The surfaces that need to be waterproofed, such as the walls and floors, are thoroughly cleaned and prepared to ensure proper adhesion of the membrane. The membrane is then applied in multiple layers, ensuring complete coverage and a seamless seal. Special attention is given to critical areas such as joints, corners, and penetrations to prevent any potential weak points. By using a waterproofing membrane, tunnels and underground structures can be effectively protected from water intrusion, groundwater pressure, and potential damage caused by moisture. This helps to maintain the structural integrity of the infrastructure, prevent water-related problems such as leaks, corrosion, or deterioration, and ensure the safety and functionality of the tunnel or underground facility.

- Q: What are the different types of waterproofing membranes?

- There are several different types of waterproofing membranes that are commonly used in construction and building projects. These membranes are designed to prevent water from penetrating through walls, roofs, or other structures, and can be applied to various surfaces. 1. Bituminous Membranes: Bitumen-based waterproofing membranes are composed of a mixture of bitumen, polymers, and reinforcement materials such as fiberglass or polyester. They are commonly used in roofing applications and can be applied as a hot or cold process. Bituminous membranes provide excellent waterproofing properties and are durable. 2. PVC Membranes: Polyvinyl chloride (PVC) membranes are synthetic materials that are highly resistant to water, chemicals, and UV radiation. They are commonly used in roofing applications, especially for flat or low-slope roofs. PVC membranes are lightweight, flexible, and easy to install. They provide long-lasting waterproofing protection and are resistant to punctures and tears. 3. EPDM Membranes: Ethylene Propylene Diene Monomer (EPDM) membranes are synthetic rubber membranes that are commonly used in roofing applications. EPDM membranes are highly durable, flexible, and resistant to UV radiation, ozone, and extreme temperatures. They can be installed as a single-ply membrane or in combination with other materials. 4. TPO Membranes: Thermoplastic Olefin (TPO) membranes are a type of single-ply roofing membrane that is commonly used in commercial and industrial applications. TPO membranes are composed of a blend of polymers and reinforcement materials. They are highly resistant to water, chemicals, and UV radiation. TPO membranes are lightweight, flexible, and easy to install. 5. Liquid Applied Membranes: Liquid applied membranes are a type of waterproofing system that is applied as a liquid and cures to form a seamless and flexible membrane. These membranes can be made from various materials such as acrylic, polyurethane, or rubber-based compounds. They are commonly used for below-grade applications, such as basements or foundations, and can also be used for roofs or other surfaces. It is important to consider the specific requirements of the project and consult with a professional to determine the most suitable type of waterproofing membrane to ensure effective and long-lasting waterproofing protection.

- Q: What is the difference between construction non-vulcanized waterproofing membrane and vulcanized waterproofing membrane?

- The vulcanized waterproofing membrane is characterized in that it consists of a vulcanized butyl rubber, a softening agent, a hard acid and a filler, wherein the parts by weight are butyl rubber: softening agent: hard acid: filler = 1 : 0.003-0.015: 0.006-0.036: 0.32-0.73, wherein the softening agent uses a mechanical oil, which can also be made into a high-strength waterproofing membrane by sandwiching a layer of the web between the two layers of the waterproofing membrane.

- Q: What is the use of waterproof membrane?

- It is the first barrier between the foundation of the project and the building, which is the first barrier to the entire project. It plays a vital role in the whole project.

- Q: Can waterproofing membranes be used on outdoor decks?

- Yes, waterproofing membranes can be used on outdoor decks. Waterproofing membranes are a popular choice for outdoor decks as they provide an effective barrier against moisture, preventing water from seeping through and causing damage to the underlying structure. These membranes are typically made of durable materials such as rubber or PVC and are designed to withstand exposure to the elements. They are applied directly onto the deck surface, creating a waterproof seal that protects the deck from rain, snow, and other forms of moisture. Additionally, waterproofing membranes can also help to prolong the lifespan of the deck by preventing water damage, rot, and decay. Therefore, using waterproofing membranes on outdoor decks is a practical and effective solution for maintaining the integrity and longevity of the deck.

- Q: Are waterproofing membranes resistant to sewage?

- Yes, waterproofing membranes are resistant to sewage. These membranes are specifically designed and manufactured to provide a barrier against various liquids, including sewage. They are made from durable materials that can withstand exposure to sewage and prevent any leakage or seepage. Waterproofing membranes create a protective layer that keeps sewage from penetrating and damaging the underlying structures. This resistance to sewage makes waterproofing membranes an effective solution for areas prone to sewage backup or high moisture content, such as basements, bathrooms, and water treatment facilities.

Send your message to us

EPDM Waterproof Rubber Membrane with 2.0mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords