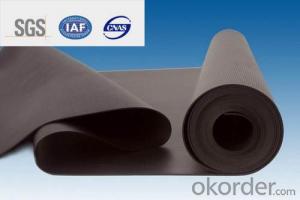

EPDM Waterproofing Roofing Membrane for Roof 1.2mm and 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Rubber Waterproof Membrane:

1.EPDM Waterproof Membrane / Roofing Material / Sheets Roofing

2.High tensile strength.

3.Good elongation.

4.UV resistant.

5.Anti-corrosion.

Main Features of EPDM Rubber Waterproof Membrane:

1) Excellent weather-ability, durability and size stability

2) Good adaptability to high and low temperature, UV resistant and anti-corrosion

3) High tensile strength and good elongation, accommodating to structure movement

4) Easy installation, solid joint, and no environmental pollution

5) Good rooting penetration resistance

6) Service life up to 50 years

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for bridges?

- Bridges can benefit from the use of a waterproofing membrane. Due to their exposure to harsh weather conditions and constant contact with water, bridges are susceptible to deterioration and structural harm. By applying a waterproofing membrane to the bridge surface, it becomes shielded against water infiltration, preventing the corroding of reinforcing steel and extending the bridge's lifespan. Acting as a barrier, the membrane prevents water from permeating the concrete and causing structural damage. Moreover, it aids in minimizing the negative impact of freeze-thaw cycles, which can further harm the bridge. Furthermore, the waterproofing membrane can enhance the overall durability and performance of the bridge, ultimately reducing maintenance and repair expenses in the long term.

- Q: Does a waterproofing membrane require any specific safety precautions during installation?

- Yes, installing a waterproofing membrane does require specific safety precautions. These may include wearing protective clothing, such as gloves and goggles, to prevent contact with chemicals or materials that may be harmful. It is important to ensure proper ventilation in the installation area to minimize exposure to potentially harmful fumes or vapors. Additionally, following manufacturer's instructions, using proper tools and equipment, and working in a well-organized manner can help prevent accidents or injuries during the installation process.

- Q: Are waterproofing membranes resistant to saltwater?

- Yes, waterproofing membranes are generally resistant to saltwater. These membranes are designed to create a barrier that prevents water from penetrating through surfaces such as roofs, walls, or foundations. They are made from materials like rubber, polyethylene, or PVC, which are inherently resistant to the corrosive effects of saltwater. This resistance allows waterproofing membranes to effectively protect structures and surfaces from water damage, even in saltwater environments. However, it is essential to choose a waterproofing membrane specifically designed for saltwater applications to ensure optimal performance and longevity.

- Q: Can a waterproofing membrane be used on EPDM roofs?

- Yes, a waterproofing membrane can be used on EPDM roofs. EPDM (ethylene propylene diene terpolymer) is a highly durable and flexible synthetic rubber roofing material commonly used for low-slope and flat roofs. While EPDM roofs are already waterproof, applying an additional waterproofing membrane can provide an extra layer of protection and enhance the roof's longevity. The waterproofing membrane can act as a barrier against water infiltration, preventing leaks and moisture damage. However, it is important to ensure that the waterproofing membrane is compatible with EPDM and follows the manufacturer's guidelines for installation to maintain the roof's integrity.

- Q: How does a waterproofing membrane handle movement in structural elements?

- A waterproofing membrane is designed to handle movement in structural elements by being flexible and accommodating any shifts or expansions that may occur. It can stretch and contract with the movement of the building, ensuring that it remains intact and continues to provide a watertight barrier.

- Q: Can a waterproofing membrane be used in elevator pits or sump pits?

- Yes, a waterproofing membrane can be used in elevator pits or sump pits to prevent water infiltration and protect the structure from potential damage caused by moisture.

- Q: Can waterproofing membranes be used on outdoor fountains?

- Indeed, outdoor fountains can benefit from the application of waterproofing membranes. The primary purpose of these membranes is to establish a protective shield that thwarts water infiltration, rendering them an excellent choice for safeguarding outdoor fountains against water-induced harm. Typically composed of water-resistant materials like rubber, PVC, or bitumen, these membranes effectively seal the fountain's structure. By applying a waterproofing membrane to an outdoor fountain, one can extend its longevity, avert leaks, and shield it from the elements.

- Q: Can a waterproofing membrane be used in kitchens?

- Yes, a waterproofing membrane can be used in kitchens. Waterproofing membranes are commonly used in areas prone to moisture, such as bathrooms and kitchens, to prevent water damage and leakage. They can be applied to various surfaces, including floors and walls, to create a waterproof barrier and protect against water infiltration. By using a waterproofing membrane in kitchens, one can ensure the longevity and durability of the space while preventing potential water-related issues.

- Q: Can waterproofing membranes be installed on uneven surfaces?

- Waterproofing membranes possess the capability to be installed on surfaces that are not even. In reality, one of the benefits of these membranes is their ability to adapt to different irregularities and unevenness on the surface. Typically, these membranes are flexible and can be easily shaped and adjusted to fit the contours of the substrate. Furthermore, certain waterproofing membranes possess self-adhesive properties or can be applied with adhesives, enabling them to effectively stick to both smooth and uneven surfaces. Nevertheless, it is crucial to emphasize that proper surface preparation is essential for a successful installation. The surface must be clean, dry, and devoid of any loose materials or debris to ensure the optimum adhesion and performance of the waterproofing membrane.

- Q: Can a waterproofing membrane be applied to wood surfaces?

- Yes, a waterproofing membrane can be applied to wood surfaces.

Send your message to us

EPDM Waterproofing Roofing Membrane for Roof 1.2mm and 1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords