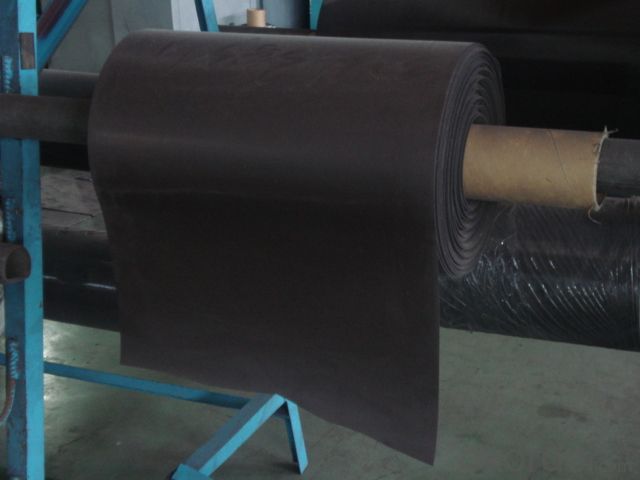

EPDM Waterproofing Membrane for Under Roof Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product instruction

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Detailed Product Description

1. High adhesive strength, durability, long after the bond;

2.Excellent weathering resistance, aging resistance;

3. Nano stabilizer added ingredients, low heat dimensional change;

4. High tensile strength, elongation, strong grass-roots stretching or cracking adaptability, resistance to low temperatures, can be adapted to -40 ℃;

5.Cold installation, easy to operate, reduce environmental pollution and improve working conditions of workers;

Application

EPDM (TBD) selfadhesive waterproofing membrane used in roofing projects, exposed roofing, building foundations, basements, storage tanks, subways, tunnels, supermarkets, airports and other buildings waterproof.

Introduction for EPDM Waterproofing Membrane:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for podium decks or plaza areas?

- Yes, a waterproofing membrane can be used for podium decks or plaza areas. Waterproofing membranes are commonly used in construction to prevent water penetration and protect the underlying structure from moisture damage. In outdoor areas like podium decks or plaza areas, where exposure to rain or other forms of water is common, a waterproofing membrane can provide an effective barrier against water infiltration and help maintain the integrity of the deck or plaza surface.

- Q: Can a waterproofing membrane be used on roofs with rooftop gardens?

- Yes, a waterproofing membrane can be used on roofs with rooftop gardens. The membrane serves as a protective layer that prevents water from seeping into the underlying structure, ensuring that the rooftop garden remains dry and well-maintained.

- Q: What is the difference between SBS and APP rolls?

- Compared to the use of SBS waterproofing membrane to use a larger range. But each has its own advantages and disadvantages, according to the local environment and the actual situation of the building in combination with the characteristics of two kinds of coil to choose materials. You have to compare the next, I can only tell you SBS waterproofing membrane prices than APP waterproofing membrane high.

- Q: Can a waterproofing membrane be used in conjunction with drainage systems?

- Yes, a waterproofing membrane can be used in conjunction with drainage systems. The membrane provides a barrier to prevent water penetration, while the drainage system helps to channel and remove any water that may accumulate. This combination ensures effective and comprehensive waterproofing for various applications such as basements, roofs, and underground structures.

- Q: Can a waterproofing membrane be used on precast plastic surfaces?

- Precast plastic surfaces can indeed benefit from the use of a waterproofing membrane. These membranes serve the purpose of establishing a shield against moisture and can be utilized on various surfaces such as concrete, metal, and plastic. By correctly implementing a waterproofing membrane, water infiltration is prevented, thus guaranteeing the long-lasting and resilient nature of the precast plastic surface. To ensure proper adhesion and effectiveness, it is crucial to select a waterproofing membrane that is compatible with plastic and adhere to the guidelines provided by the manufacturer during application.

- Q: How does a waterproofing membrane handle movement joints or cracks?

- A waterproofing membrane is designed to handle movement joints or cracks by providing a flexible and stretchable barrier that can accommodate the shifting or settling of a structure. When there are movement joints or cracks present, the membrane is applied in a way that creates a continuous and seamless layer over the surface. The flexibility of the waterproofing membrane allows it to move and adapt to changes in the structure, such as expansion or contraction, without compromising its integrity. This is especially important in areas where there is significant movement or where cracks are prone to develop, such as in concrete slabs or foundations. In the case of movement joints, the membrane is typically terminated or split at the joint to allow for movement without creating stress or tension on the membrane. This ensures that any movement or shifting of the structure does not cause the membrane to tear or fail. For cracks, the waterproofing membrane is applied directly over the surface, bridging the gap and sealing it off from water infiltration. The flexible nature of the membrane allows it to stretch and conform to the shape of the crack, effectively sealing it and preventing further water damage. Overall, a waterproofing membrane is designed to handle movement joints or cracks by providing a durable and flexible barrier that can accommodate structural movements and prevent water penetration. This helps to maintain the integrity of the structure and protect it from water damage.

- Q: Can a waterproofing membrane be used in geotechnical applications?

- Indeed, geotechnical applications can make effective use of waterproofing membranes. These membranes are commonly employed to safeguard structures against water infiltration and are applied to various surfaces such as roofs, basements, and foundations. In geotechnical applications, these membranes serve the purpose of preventing water from seeping into the soil, thus averting erosion and stabilizing slopes. They can be positioned either horizontally or vertically to establish a barrier that hinders water penetration, which proves particularly advantageous in retaining walls, embankments, and dams. Furthermore, waterproofing membranes can be used to regulate water flow and enhance drainage in geotechnical projects. All in all, incorporating a waterproofing membrane into geotechnical applications can significantly enhance the longevity and performance of structures while effectively safeguarding them against water-related issues.

- Q: Can a waterproofing membrane be used in conjunction with roofing materials?

- Yes, a waterproofing membrane can be used in conjunction with roofing materials. In fact, it is quite common to use a waterproofing membrane as an added layer of protection for roofs. The membrane is typically applied directly on top of the roofing material, creating an additional barrier against water penetration. This is especially beneficial in areas prone to heavy rainfall or where the roof is exposed to high levels of moisture. The waterproofing membrane helps to prevent leaks, extend the lifespan of the roof, and protect the structure from potential water damage. Additionally, the membrane can also provide added insulation and energy efficiency benefits. Overall, using a waterproofing membrane in conjunction with roofing materials is a wise choice to enhance the waterproofing capabilities and durability of the roof.

- Q: Can a waterproofing membrane be applied on top of existing coatings?

- Yes, a waterproofing membrane can be applied on top of existing coatings. However, it is essential to ensure that the existing coating is in good condition and properly adhered to the surface. Additionally, the compatibility between the existing coating and the waterproofing membrane should be checked to ensure proper adhesion and effectiveness. A professional evaluation is recommended to determine the suitability and compatibility of applying a waterproofing membrane over existing coatings.

- Q: Are waterproofing membranes suitable for wastewater treatment plants?

- Yes, waterproofing membranes are suitable for wastewater treatment plants. Wastewater treatment plants deal with the treatment and processing of wastewater, which contains a variety of chemicals, contaminants, and bacteria. These substances can be highly corrosive and can cause damage to the infrastructure of the plant if not properly protected. Waterproofing membranes provide an effective barrier against water and chemical penetration, preventing leaks, seepage, and corrosion. They can be applied to various areas of the plant, including tanks, basins, pipelines, and concrete structures. Additionally, waterproofing membranes are durable, long-lasting, and can withstand the harsh conditions and chemicals present in wastewater treatment plants. Therefore, using waterproofing membranes in wastewater treatment plants is a recommended practice to ensure the integrity, longevity, and efficiency of the infrastructure.

Send your message to us

EPDM Waterproofing Membrane for Under Roof Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords