EPDM Waterproof Membrane with Fleeced Back for Liner Ponds

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

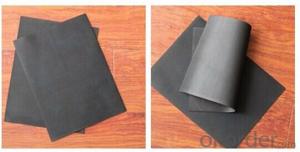

EPDM Waterproof Membrane with Fleeced Back for Liner Ponds

Description Of EPDM Waterproof Membrane with Fleeced Back for Liner Ponds:

We have more than 15 years experience in development & manufacture construction materials such as waterproof membrane,waterproof coils,waterproof panels,waterproof coating,geomembrane,geotextiles etc.Depending on our full set production line,well equipped laboratory,cooperation with institute&college and experienced employees,we have successfully developed and consolidated domestic and foreign market.With a high-tech team of research and development,we have our patent technology, the spray application waterproof membrane.They are the most advanced technology in tunnel and underground projects.Quality is our life,customer satisfaction is our goal, to build the world be more beautiful is our responsibility!

Main Features of EPDM Waterproof Membrane with Fleeced Back for Liner Ponds:

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

Specifications of EPDM Waterproof Membrane with Fleeced Back for Liner Ponds:

| Material | EPDM Rubber |

| Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

| Thick | 1.2mm, 1.5mm, 2.0mm |

| Type | Vulcanized & Weldable |

| Pattern | Non-reinforced (homogeneous) |

| Certificate | ISO9001/14001 |

Applications of EPDM Waterproof Membrane with Fleeced Back for Liner Ponds:

1. Roofs, Basement, Toilet

2. Industrial and civil building waterproofing

3. Geo-synthetic liner for swimming pool, channels, irrigation system

4. Especially suit for projects with high requirements in durability, anti-corrosion and deformation

IMages of EPDM Waterproof Membrane with Fleeced Back for Liner Ponds:

FAQ of EPDM Waterproof Membrane with Fleeced Back for Liner Ponds:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be pre-fabricated or pre-made for easy installation?

- Yes, a waterproofing membrane can be pre-fabricated or pre-made for easy installation. In fact, many manufacturers offer pre-made waterproofing membranes that are specifically designed to simplify the installation process. These membranes are typically manufactured in controlled factory conditions, ensuring consistent quality and reducing the potential for errors during installation. Pre-fabricated waterproofing membranes are made from various materials such as bitumen, PVC, EPDM, or TPO, and come in different forms such as sheets or rolls. They are designed to be easily transported and installed on-site. The advantages of using pre-fabricated waterproofing membranes include increased efficiency, reduced labor costs, and improved installation quality. By eliminating the need for on-site fabrication, contractors can save time and resources. Additionally, pre-made membranes often come with detailed installation instructions, making it easier for contractors to ensure proper installation. Furthermore, pre-fabricated waterproofing membranes can be tailored to fit specific project requirements, such as size, shape, or slope. This customization helps to ensure a seamless and effective waterproofing solution. Overall, using pre-fabricated or pre-made waterproofing membranes can significantly simplify the installation process and provide a reliable and durable waterproofing solution for various applications, including roofs, basements, and foundations.

- Q: Can a waterproofing membrane be used in mining or excavation projects?

- Yes, a waterproofing membrane can be used in mining or excavation projects. Waterproofing membranes are designed to prevent the ingress of water and other liquids, making them an ideal solution for areas that are prone to water intrusion, such as mines or excavations. These membranes are typically made from durable materials, such as rubber or bitumen, and are applied to the walls, floors, or roofs of these structures to create a watertight barrier. By using a waterproofing membrane, mining and excavation projects can minimize the risk of water damage, protect equipment and infrastructure, and ensure a safe working environment for workers.

- Q: Is a waterproofing membrane suitable for use in areas with high groundwater levels?

- Yes, a waterproofing membrane is suitable for use in areas with high groundwater levels. A waterproofing membrane is designed to prevent water penetration and can be effective in creating a barrier against groundwater. These membranes are typically made from materials such as bitumen, PVC, or EPDM, which are highly resistant to water and can withstand high hydrostatic pressure. They are specifically engineered to provide a watertight seal, preventing water from seeping into structures or underground spaces. Therefore, a waterproofing membrane is an ideal solution for areas with high groundwater levels, as it can effectively protect against water intrusion and potential damage to buildings or infrastructure.

- Q: Can a waterproofing membrane be used for modular buildings or container homes?

- Yes, a waterproofing membrane can be used for modular buildings or container homes. It provides a protective layer against moisture, preventing water damage and enhancing the durability of the structure.

- Q: Can a waterproofing membrane be used on zinc surfaces?

- Yes, a waterproofing membrane can be used on zinc surfaces. Zinc is a durable and corrosion-resistant material commonly used in various applications, including roofing and cladding. Applying a waterproofing membrane on zinc surfaces can provide an additional layer of protection against water intrusion and moisture damage. It can help prevent leaks, extend the lifespan of the zinc surface, and maintain its overall integrity. However, it is important to ensure that the waterproofing membrane is compatible with zinc and specifically designed for such applications. It is recommended to consult with a professional or manufacturer to determine the best waterproofing solution for zinc surfaces.

- Q: Can a waterproofing membrane be used on tunnels with communication systems?

- Yes, a waterproofing membrane can be used on tunnels with communication systems. The membrane can help protect the communication systems from water damage and ensure their proper functioning.

- Q: Does a waterproofing membrane require any special considerations for installation in high-humidity areas?

- Special considerations are required when installing a waterproofing membrane in high-humidity areas. The presence of high humidity can impact the membrane's performance if not addressed properly during installation. Here are some important points to keep in mind: 1. Moisture management is crucial: Before installing the waterproofing membrane, it is essential to control moisture levels in the area. Thoroughly drying the surface and resolving any existing moisture issues or leaks is necessary. 2. Vapor barriers are beneficial: To prevent moisture from seeping through the membrane, it is advisable to install a vapor barrier underneath. This is particularly important in consistently humid environments. 3. Adequate ventilation is key: To avoid excessive moisture buildup, proper airflow and ventilation systems should be in place. This promotes drying and prevents condensation, which can compromise the integrity of the waterproofing membrane. 4. Choose the right membrane: Not all waterproofing membranes are suitable for high-humidity areas. It is crucial to select a membrane specifically designed and recommended for such environments. Look for membranes with high moisture resistance and durability. 5. Professional installation is recommended: Proper installation techniques are vital for the long-term performance of the waterproofing membrane. In high-humidity areas, it is advisable to hire experienced contractors who have worked in similar conditions. By considering these factors, you can ensure that the waterproofing membrane effectively protects against moisture in high-humidity areas.

- Q: Can a waterproofing membrane be used for stadiums or arenas?

- Yes, a waterproofing membrane can be used for stadiums or arenas. Waterproofing membranes are commonly used in construction to prevent water infiltration, and they can be applied to the roofs, walls, or foundations of stadiums or arenas to protect them from water damage. These membranes are designed to withstand harsh weather conditions and provide long-lasting protection, making them suitable for large-scale structures like stadiums or arenas.

- Q: Can a waterproofing membrane be used for plant rooms or mechanical spaces?

- Yes, a waterproofing membrane can be used for plant rooms or mechanical spaces. These areas often require protection against water damage due to the presence of pipes, equipment, or other mechanical systems. A waterproofing membrane provides an effective barrier to prevent water intrusion and protect the integrity of the space.

- Q: Are there any limitations to using a waterproofing membrane?

- Yes, there are some limitations to using a waterproofing membrane. One limitation is that the membrane can be punctured or damaged during installation, which can compromise its effectiveness. Additionally, waterproofing membranes may not be suitable for all types of surfaces or structures, and certain conditions such as extreme temperatures or excessive movement can affect their performance. Moreover, the lifespan of a waterproofing membrane can vary depending on factors like maintenance, exposure to UV rays, and overall wear and tear.

Send your message to us

EPDM Waterproof Membrane with Fleeced Back for Liner Ponds

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords