EPDM Waterproof Membrane for Pond Liner Use with Pure Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

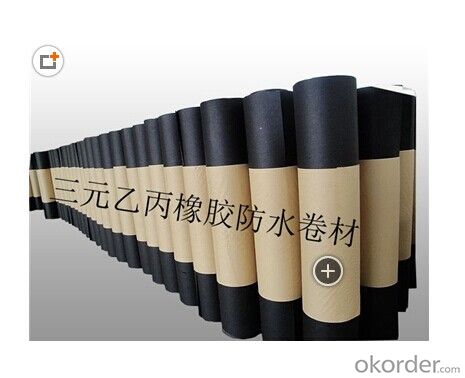

EPDM Waterproof Membrane

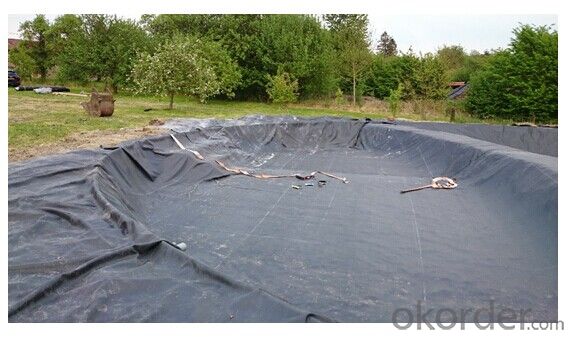

Introduction for EPDM Waterproof Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Characteristics for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

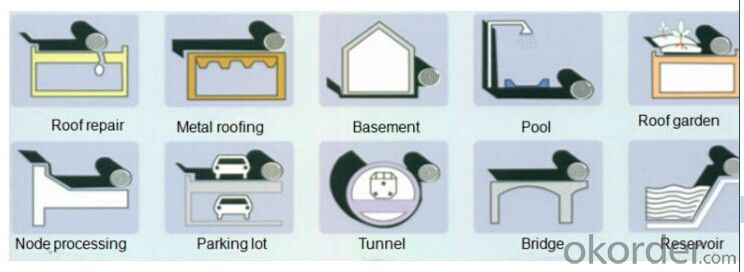

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Type | EPDM |

Material | EPDM Rubber |

Thickness | 1.2mm,1.5mm,2.0mm |

Length | 20m/roll |

Width | 1.2m |

Usage | roof/walls/bathroom/tunnel/basement/bridge/road/underground, |

Application method | Hot melt |

Length | 20m |

Surface | Smooth surface,fleece surface |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used in bathrooms?

- Yes, a waterproofing membrane can be used in bathrooms. In fact, it is highly recommended to use a waterproofing membrane in bathrooms to prevent water damage and leakage. The membrane is typically applied on the walls and floors, creating a barrier that prevents water from seeping through and causing structural damage or mold growth. This is especially important in areas such as showers and around bathtubs where water exposure is high. Waterproofing membranes are designed to withstand moisture and provide long-lasting protection, ensuring the integrity of the bathroom and extending its lifespan.

- Q: Does a waterproofing membrane have any impact on the indoor air quality?

- Yes, a waterproofing membrane can have an impact on indoor air quality. Waterproofing membranes are commonly used to prevent water infiltration into buildings, especially in areas prone to moisture, such as basements, roofs, and foundations. These membranes are typically made of synthetic materials, such as polyethylene or polypropylene, which can release volatile organic compounds (VOCs) into the air. VOCs are chemicals that can evaporate at room temperature and can have adverse effects on indoor air quality. When released into the air, VOCs can contribute to the formation of indoor air pollutants, such as formaldehyde or benzene. Prolonged exposure to VOCs can cause various health issues, including eye, nose, and throat irritation, headaches, dizziness, and even respiratory problems. However, it is important to note that not all waterproofing membranes have the same impact on indoor air quality. Some manufacturers have developed low VOC or VOC-free waterproofing membranes, which are designed to minimize the release of harmful chemicals into the air. These products undergo rigorous testing to ensure they meet stringent air quality standards. Additionally, proper installation and ventilation can also play a significant role in mitigating any potential negative impact on indoor air quality. Adequate ventilation systems can help remove any VOCs or other pollutants from the air, preventing them from accumulating and causing health issues. Therefore, when considering the installation of a waterproofing membrane, it is crucial to select a product that has been tested for low VOC emissions and to ensure proper ventilation is in place to maintain good indoor air quality. Consulting with professionals in the field can provide valuable guidance in choosing the most appropriate waterproofing solution for your specific needs while minimizing any potential impact on indoor air quality.

- Q: Can a waterproofing membrane be used for elevator shafts?

- A waterproofing membrane is an effective solution for elevator shafts. Elevator shafts are prone to water infiltration, which can harm the building's structure and the elevator system itself. By using a waterproofing membrane, water can be prevented from entering the shaft, safeguarding it against moisture-related issues such as corrosion, mold, and mildew. Typically, the membrane is applied to the shaft's walls and floors, creating a barrier that blocks water. To ensure optimal effectiveness and durability, it is important to select a waterproofing membrane specifically designed for elevator shafts. Moreover, proper installation and maintenance are crucial for the long-term performance of the waterproofing system. In conclusion, employing a waterproofing membrane for elevator shafts is a recommended measure to shield against water damage and uphold the elevator system's functionality and safety.

- Q: How long does a waterproofing membrane last?

- The lifespan of a waterproofing membrane can vary depending on several factors. Generally, a well-installed and properly maintained waterproofing membrane can last between 10 to 20 years. However, this estimate can be influenced by various factors such as the quality of the membrane material, the level of exposure to environmental elements, the frequency of foot traffic or other stressors, and the overall maintenance and care provided. It is important to note that regular inspections and maintenance are crucial for prolonging the lifespan of a waterproofing membrane. Additionally, following manufacturer guidelines and recommendations can ensure optimal performance and increase the longevity of the membrane.

- Q: Are waterproofing membranes resistant to oil and grease?

- Yes, waterproofing membranes are often resistant to oil and grease. These membranes are designed to create a barrier against water infiltration, and many of them are also made to withstand exposure to various chemicals, including oil and grease. This resistance is typically achieved through the use of specialized materials and coatings that are able to repel or prevent absorption of oil and grease. However, it is important to note that the level of resistance can vary depending on the specific type and brand of the waterproofing membrane. Therefore, it is advisable to consult the manufacturer's specifications or seek professional advice to ensure the membrane chosen is suitable for the specific application and level of oil and grease exposure.

- Q: Can a waterproofing membrane be used in kitchens?

- Certainly! Kitchens can indeed benefit from the application of a waterproofing membrane. It is strongly advised to employ such membranes in spaces that are susceptible to moisture and water, like kitchens. These specialized membranes are engineered to establish a shield against water, thwarting its infiltration into the foundation and safeguarding it against harm. They are frequently utilized on floors, walls, and even countertops to ensure a tight seal that resists water damage, the growth of mold, and various other complications. Moreover, waterproofing membranes can aid in soundproofing while enhancing the sturdiness and lifespan of kitchen surfaces.

- Q: Can a waterproofing membrane be used on tunnels with seismic protection systems?

- Yes, a waterproofing membrane can be used on tunnels with seismic protection systems. In fact, it is highly recommended to use a waterproofing membrane in such tunnels to prevent water ingress and subsequent damage to the structure. Seismic protection systems are designed to absorb and dissipate the energy generated by an earthquake, ensuring the safety and stability of the tunnel. However, these systems do not provide any protection against water infiltration. By installing a waterproofing membrane, the tunnel can be safeguarded against potential water leaks and seepage, which can lead to corrosion of reinforcement, deterioration of concrete, and overall structural damage. It is important to select a waterproofing membrane specifically designed for use in tunnels, considering factors such as flexibility, durability, and resistance to movement caused by seismic events. Additionally, proper detailing and installation techniques should be employed to ensure a seamless and effective waterproofing system that works in conjunction with the tunnel's seismic protection measures.

- Q: Can a waterproofing membrane be used as a vapor barrier?

- Indeed, a vapor barrier can be achieved by utilizing a waterproofing membrane. The main purpose of waterproofing membranes is to obstruct the flow of water across various surfaces, such as roofs or foundations. As a result of their water-repelling capabilities, these membranes simultaneously serve as vapor barriers, hindering the movement of water vapor. This serves to minimize the likelihood of condensation and other moisture-related problems within a structure. Nonetheless, it is crucial to acknowledge that not all waterproofing membranes possess the same degree of vapor resistance. Consequently, it is imperative to carefully select a waterproofing membrane that is explicitly designed to function as a vapor barrier, should this be a necessity for the intended application.

- Q: What are the different thickness options for a waterproofing membrane?

- The different thickness options for a waterproofing membrane typically range from 10 mils to 40 mils, with some specialty options available in even greater thicknesses.

- Q: Can a waterproofing membrane be used for a planter box waterproofing?

- Yes, a waterproofing membrane can be used for planter box waterproofing. The membrane helps to prevent water from seeping through the planter box and causing damage to the surrounding structures. It acts as a barrier between the soil and the planter box, ensuring that water stays contained within the box.

Send your message to us

EPDM Waterproof Membrane for Pond Liner Use with Pure Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords