EPDM Self-adhesive Waterproof Membrane for Ro9999oftop Rubber Foam

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

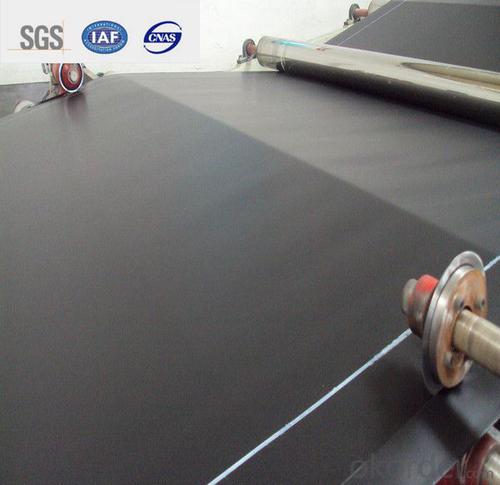

Description Of EPDM Self-adhesive Waterproof Membrane for Rooftop Rubber Foam :

Self adhesive waterproof rolling material:

thickness:1.2/1.5/2.0mm

length/roll:10/20m

width/roll:1.02m

Low temperature:-15 -20,-30

Main Features of EPDM Self-adhesive Waterproof Membrane for Rooftop Rubber Foam :

1 High tear

2 High puncturing strength

3 Great temperature resistance.

4 High dimensional stability

Specifications of EPDM Self-adhesive Waterproof Membrane for Rooftop Rubber Foam :

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

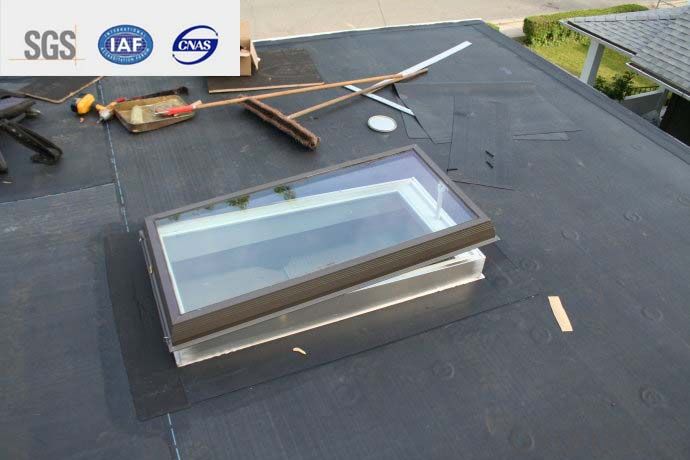

Applications of EPDM Rubber Waterproof Membrane:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can waterproofing membranes be used on foundation walls?

- Indeed, it is possible to utilize waterproofing membranes on foundation walls. These membranes possess a specific design that aims to impede the infiltration of water and are commonly employed on foundation walls to safeguard against moisture and water-related harm. Typically, these membranes consist of resilient materials like rubberized asphalt, thermoplastic, or PVC, which exhibit durability and resistance to water penetration. The installation of these membranes occurs on the outer side of the foundation walls, thereby serving as a highly efficient barrier against water, effectively averting its seepage into the basement or crawl space. Without a doubt, waterproofing membranes constitute an indispensable element in the realm of building construction, as they actively contribute to the preservation of the foundation's structural integrity, preventing adverse consequences such as water damage, mold growth, and foundation settlement.

- Q: Does a waterproofing membrane prevent efflorescence or mineral deposits on surfaces?

- Yes, a waterproofing membrane can help prevent efflorescence or mineral deposits on surfaces. Efflorescence occurs when water-soluble salts in concrete or masonry materials dissolve and then migrate to the surface, leaving behind a white powdery residue. By preventing water from penetrating the surface, a waterproofing membrane can minimize the amount of water available to dissolve these salts and transport them to the surface. This can significantly reduce the occurrence of efflorescence. Similarly, mineral deposits can form on surfaces when water containing dissolved minerals evaporates, leaving behind the minerals as a residue. A waterproofing membrane can prevent water from reaching the surface, thereby reducing the formation of mineral deposits. However, it's important to note that while a waterproofing membrane can help minimize these issues, it may not completely eliminate them, especially if there are underlying issues with the material or water source. Regular maintenance and proper installation of the waterproofing membrane are also crucial for its effectiveness in preventing efflorescence or mineral deposits on surfaces.

- Q: On the roof of the waterproofing membrane paving the direction of what are the requirements

- ?As for the upper and lower layers are not allowed between the vertical paving, the reason is that after the paving more heavy joints, and heavy seam is the most vulnerable to leakage of weak parts. ????????Dragon waterproof experts to remind you: things always have a dual nature. In the southern region, the temperature is high, rainy days, to the web paving brought a lot of difficulties. In order to waterproof roofing, when the rain is easy to coil joints, in addition to less than 3% of the roof slope, the remaining slope of the roof coil should take the vertical roof direction paving.

- Q: Does a waterproofing membrane require any specific cleaning or maintenance procedures?

- To ensure the longevity and effectiveness of a waterproofing membrane, it is necessary to follow specific cleaning and maintenance procedures. Regular cleaning and maintenance are important to prevent the accumulation of debris, dirt, and contaminants that could compromise the membrane's ability to keep water out. The exact procedures for cleaning and maintenance may vary depending on the type of waterproofing membrane used, but there are some general guidelines to follow. Firstly, it is crucial to frequently inspect the membrane for any signs of damage, such as cracks, tears, or deterioration. If any issues are found, they should be addressed promptly to prevent further damage. When it comes to cleaning, it is recommended to use a soft-bristle broom or a leaf blower to remove loose debris or dirt from the membrane surface. It is important to avoid harsh chemicals or abrasive materials that could harm the membrane. Instead, a mild detergent or specialized cleaning solution recommended by the manufacturer should be used. The surface can be gently scrubbed with a soft brush or sponge and thoroughly rinsed with clean water. Additionally, it is vital to keep the surrounding drainage systems clear and free from obstructions. Regular inspection and cleaning of gutters, downspouts, and drains are necessary to ensure proper water flow and prevent potential water damage. Lastly, it is advisable to have the waterproofing membrane professionally inspected and maintained on a regular basis. This will help identify any potential issues early on and ensure that the membrane is functioning optimally. By following these specific cleaning and maintenance procedures, the lifespan of the waterproofing membrane can be prolonged, and its effectiveness in preventing water infiltration can be maintained.

- Q: Can a waterproofing membrane be used to repair existing water leaks or damage?

- Yes, a waterproofing membrane can be used to repair existing water leaks or damage. Waterproofing membranes are designed to create a barrier that prevents water from penetrating through surfaces such as roofs, walls, or foundations. By applying a waterproofing membrane to areas where water leaks or damage have occurred, it can effectively seal off the affected area and prevent further water intrusion. However, it is important to note that the success of the repair depends on the extent of the damage and the quality of the waterproofing membrane used. It is always recommended to consult with a professional to assess the situation and determine the best course of action for repairing existing water leaks or damage.

- Q: Roof SBS waterproofing membrane additional layer needs to be wide

- Asphalt waterproofing membrane is in the base tire (such as base paper, fibrous fabric) dip on asphalt, and then spread in the surface of powder or sheet of the isolation material made of curled sheet waterproof material.

- Q: Are waterproofing membranes suitable for stadium structures?

- Yes, waterproofing membranes are suitable for stadium structures. These membranes provide an effective barrier against water infiltration, protecting the structure from potential damage caused by moisture. Additionally, waterproofing membranes are flexible and can accommodate movement in the stadium's structure without compromising their effectiveness.

- Q: What is the PEDM waterproofing membrane material?

- It is widely used at home and abroad high-grade waterproof material for roof, underground, subway, bridges and require a higher waterproofing works.

- Q: Can a waterproofing membrane be used for below-grade applications?

- Yes, a waterproofing membrane can be used for below-grade applications. In fact, it is commonly used in construction projects to prevent water penetration in below-grade structures such as basements, foundations, and retaining walls. A waterproofing membrane is designed to provide a barrier against water and moisture, protecting the structure from potential damage caused by water infiltration. It is typically applied to the exterior side of the below-grade structure and serves as a protective layer that prevents water from seeping into the building. Waterproofing membranes for below-grade applications are specifically formulated to withstand the high hydrostatic pressure that can be exerted by the surrounding soil and water. They are usually made from durable materials such as modified bitumen, rubberized asphalt, or polyvinyl chloride (PVC), which are capable of withstanding the harsh conditions typically found below grade. Additionally, these membranes are designed to be flexible, allowing them to accommodate for any movement or settlement that may occur in the structure over time. Overall, using a waterproofing membrane for below-grade applications is an effective and reliable method to prevent water intrusion and protect the integrity of the structure.

- Q: Can a waterproofing membrane be used in stadiums or sports complexes?

- Stadiums and sports complexes can indeed benefit from the use of waterproofing membranes. It is highly advisable to employ waterproofing solutions in these types of structures to safeguard them against water damage and leaks. The purpose of a waterproofing membrane is to serve as a barrier, preventing water from infiltrating the concrete or other construction materials employed in the stadium or sports complex. This is especially crucial in regions where heavy rainfall or high humidity levels are prevalent. Implementation of a waterproofing membrane on the roofs, walls, and foundations of these edifices helps guarantee their longevity and structural integrity, while also offering a comfortable and secure environment for athletes and spectators alike. Waterproofing membranes are specifically designed to endure the pressures and movements associated with the building, making them an optimal choice for stadiums and sports complexes. Additionally, contemporary waterproofing membranes come in diverse forms, including liquid-applied or sheet membranes. This allows for flexibility in application and compatibility with various construction materials.

Send your message to us

EPDM Self-adhesive Waterproof Membrane for Ro9999oftop Rubber Foam

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords